Water-resistant super-large section combined segmental conductor

A combination of split and conductor technology, applied in the direction of conductors, insulated conductors, insulated cables, etc., can solve the problems of reducing the service life of cables, accelerating cable electrical aging, corrosion, etc., to increase the conductor cross-section, strong water blocking function, and improve transmission capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

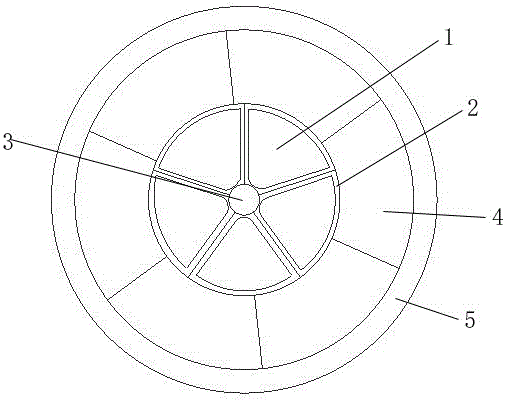

[0013] Such as figure 1 As shown, a water-blocking super large cross-section combined segmented conductor, the conductor center is formed by a plurality of segmented fan-shaped conductor strands 1 with the same size and cross-sectional shape, and fan-shaped strands are arranged outside each fan-shaped conductor strand water-blocking layer 2; water-blocking rope 3 is filled in the central gap after a plurality of fan-shaped conductor strands are assembled; a number of split corrugated conductor strands 4 are assembled outside the fan-shaped strand water-blocking layer, and finally the split corrugated-type A water-blocking layer 5 is provided outside the conductor strand; the section of the segmented corrugated conductor strand is 3%-8% larger than the segmented sector-shaped conductor strand, and the segmented sector-shaped conductor strand is larger than the segmented corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com