Over-temperature alarm wiring device and system

A wiring device and terminal technology, which is applied in the direction of thermal switch components, etc., can solve the problems of not being able to monitor the contact temperature in real time, time-consuming and labor-intensive real-time performance, and low work efficiency, so as to achieve convenient over-temperature alarm, reduce workload, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

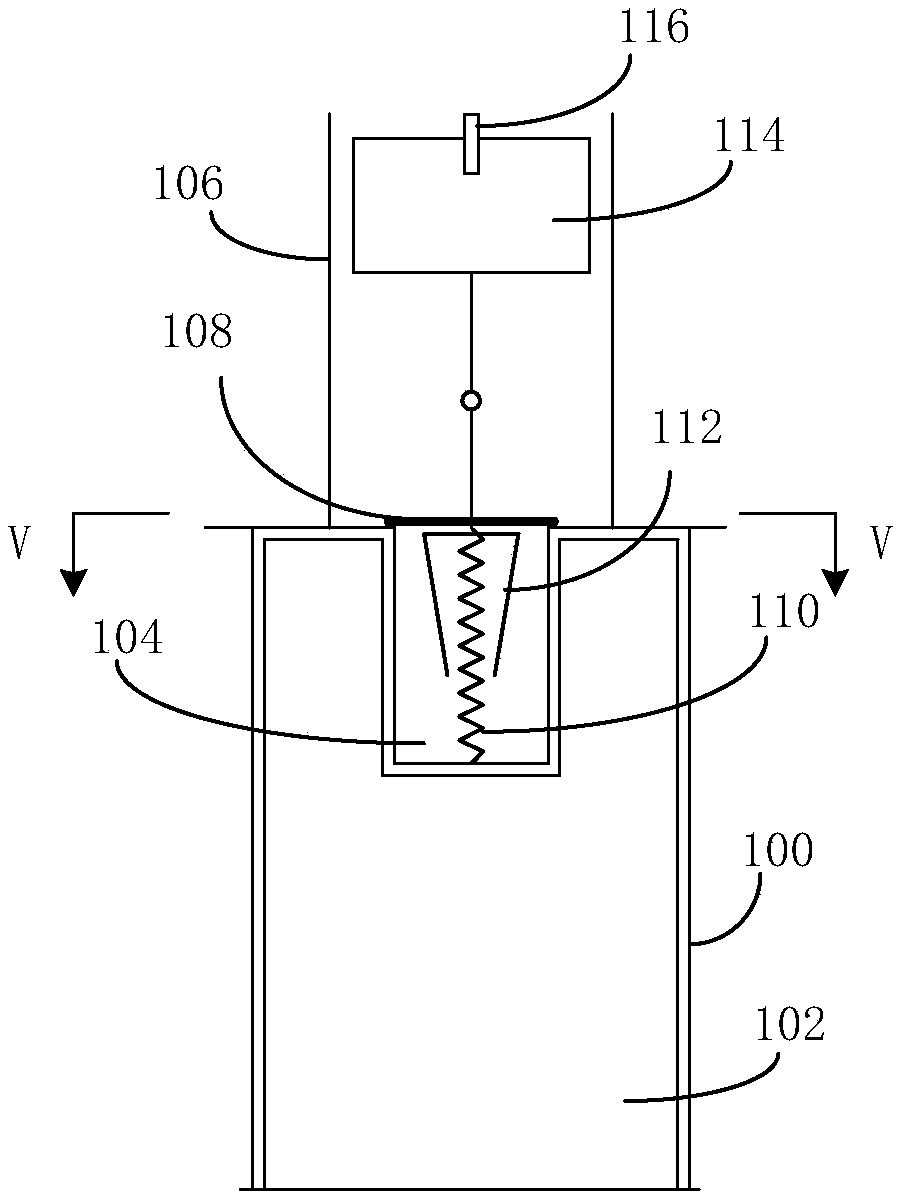

[0034] see figure 1 A structural schematic diagram of an over-temperature alarm wiring device shown; the device includes a wiring unit and an alarm unit; wherein the wiring unit includes a first insulating sleeve 100 and a connecting cylinder 102 matching the inner diameter of the first insulating sleeve 100 ; The terminal cylinder 102 is provided with a spiral groove ( figure 1 not shown in ); the spiral groove is used to accommodate the terminal; the center of the top of the above-mentioned terminal is provided with a cylindrical concave cavity with an inner diameter smaller than the inner diameter of the terminal;

[0035]The above-mentioned alarm unit includes a temperature-sensing chamber 104, an alarm component fixed at the center of the bottom of the temperature-sensing chamber, and a second insulating sleeve 106 outside the alarm component; the inner diameter of the above-mentioned temperature-sensing chamber 104 matches the inner diameter of the cylindrical recessed c...

Embodiment 2

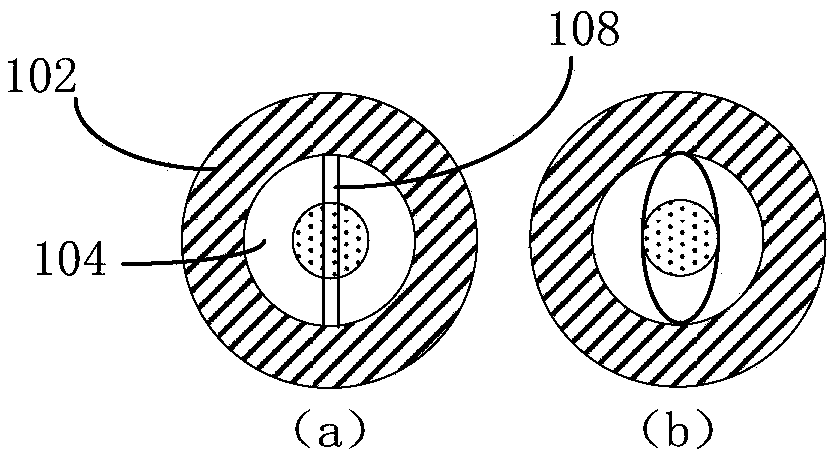

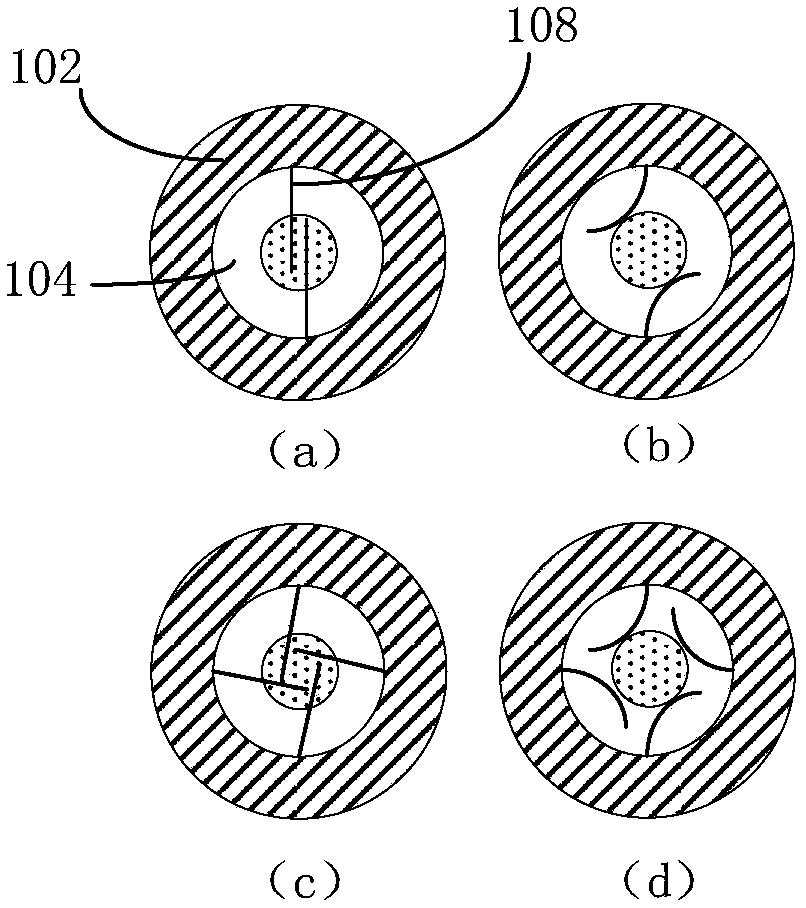

[0040] For a detailed description of the over-temperature alarm wiring device provided in the first embodiment, refer to figure 2 shown figure 1 The first sectional view along the V-V line; figure 2 A first arrangement of multiple temperature-sensitive metal sheets is shown, wherein the number of multiple temperature-sensitive metal sheets 108 is two; both ends of the temperature-sensitive metal sheets 108 are fixed to the edge of the opening of the temperature-sensing cavity 104 position; the positions of both ends of the temperature-sensitive metal sheet 108 are opposite to the temperature-sensing chamber; specifically, the length of the two temperature-sensitive metal sheets 108 can be the same as the diameter of the temperature-sensing chamber, so that the two temperature-sensitive metal sheets can be In the case of deformation, it is just fixed at the diameter of the opening of the temperature sensing chamber.

[0041] The above two temperature-sensitive metal sheets ...

Embodiment 3

[0056] see Figure 8 Shown is a schematic structural diagram of an over-temperature alarm wiring system; the system includes the above-mentioned over-temperature alarm wiring device 800 , a power line terminal 802 , and a substation or power distribution device 804 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com