Ultra-thick copper printed board and solder resisting processing method

An ultra-thick copper and printed board technology, applied in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve problems such as difficult operation, unsuitable processing, screen printing alignment problems, etc., to avoid voids and air bubbles Produce, improve the efficiency of solder mask processing, improve the effect of solder mask quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

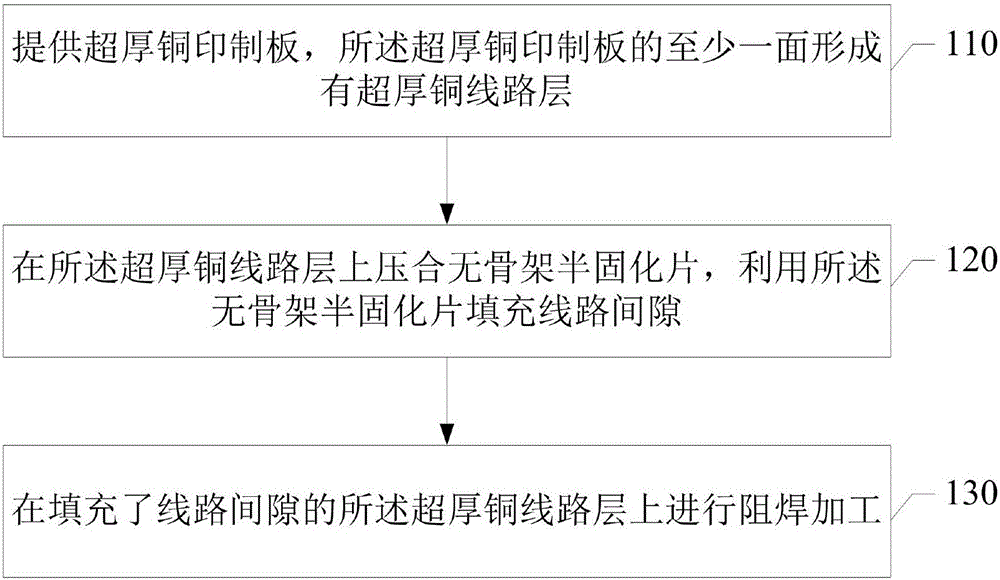

[0024] Please refer to figure 1 , an embodiment of the present invention provides a solder resist processing method for an ultra-thick copper printed board, the method may include:

[0025] 110. Provide an ultra-thick copper printed board, at least one side of the ultra-thick copper printed board is formed with an ultra-thick copper circuit layer, and the thickness of the ultra-thick copper circuit layer is not less than 10OZ.

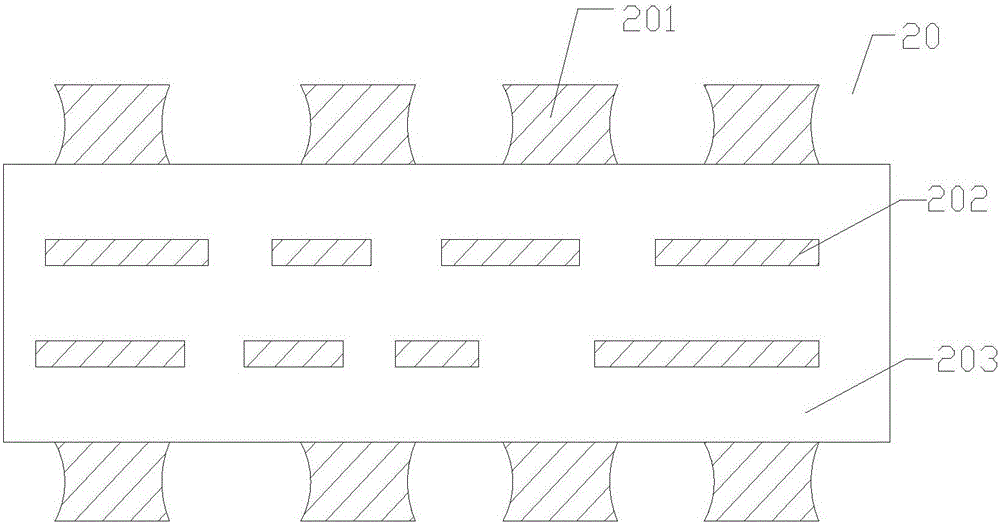

[0026] In the embodiment of the present invention, the ultra-thick copper printed board refers to a printed board with an ultra-thick copper foil layer on one or both sides. Such as Figure 2a As shown, it is a structural schematic diagram of an ultra-thick copper printed board 20 that has completed the outer layer pattern processing. The ultra-thick copper printed board 20 includes: an ultra-thick copper circuit layer 201 located on one or both sides, and a layer located on the inner layer or multiple inner wiring layers 202, and an insulating layer...

Embodiment 2

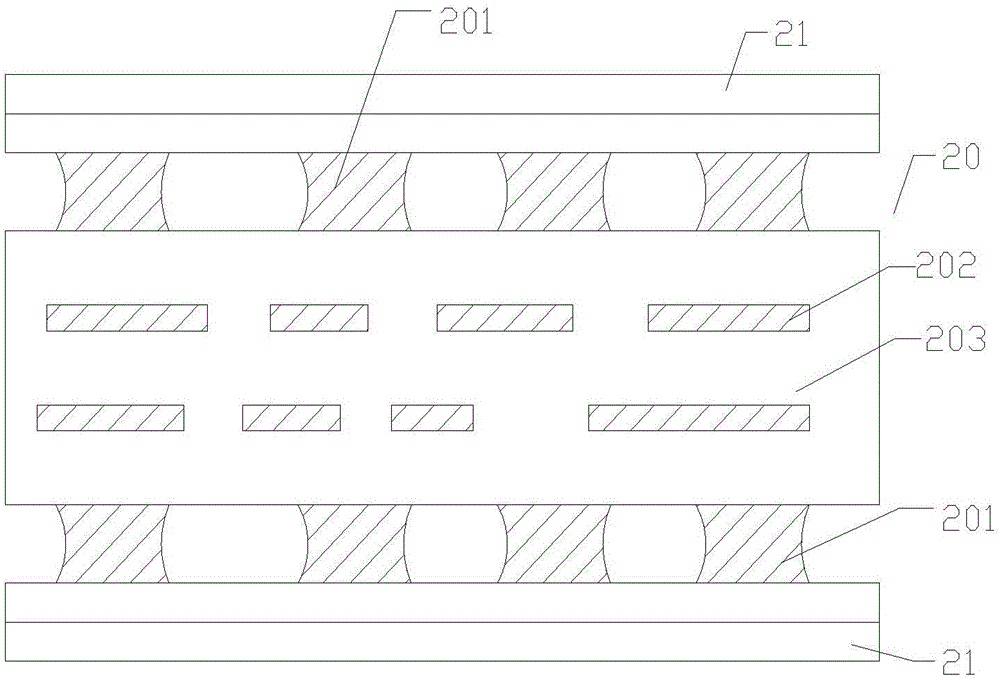

[0041] Please refer to Figure 2e , the embodiment of the present invention provides an ultra-thick copper printed board 20, at least one side of the ultra-thick copper printed board 20 is formed with an ultra-thick copper circuit layer 201, and the thickness of the ultra-thick copper circuit layer 201 is not less than 10OZ ; The circuit gap of the ultra-thick copper circuit layer 201 is filled with a skeleton-free prepreg 21 ; the solder resist ink 22 is set on the ultra-thick copper circuit layer 201 filled with circuit gaps.

[0042] Optionally, the thickness of the ultra-thick copper circuit layer 201 is not less than 15 OZ.

[0043] Above, the embodiment of the present invention discloses an ultra-thick copper printed board, which can be prepared by the method disclosed in Embodiment 1. For a more detailed description of the ultra-thick copper printed board, please Refer to the description in Example 1.

[0044] It can be seen from the above that in some feasible embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com