Preparation method of fruity-flavor black tea

A technology of black tea and fruity aroma, which is applied in the field of preparation of fruity black tea, which can solve the problems of long withering time, unsatisfactory black tea quality characteristics, and insufficient long-lasting tea aroma, so as to achieve the effect of bright red tea soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

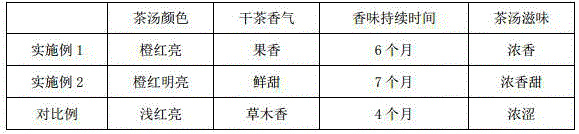

Examples

Embodiment 1

[0030] The preparation method of the fruity black tea of the present embodiment may further comprise the steps:

[0031] The first step: pick spring tea in March every year, and the spring tea is selected from the alpine tea farm in Meitan County, Zunyi City, Guizhou Province. When picking spring tea, only fresh leaves with one bud and one leaf at the top of the tea tree are picked as raw materials;

[0032] Step 2: Put the picked fresh leaves into the withering tank, spread the fresh leaves in the withering tank with a thickness of 2cm, first pass into the withering tank with air-conditioning at -3°C for 1 hour, and then pass through the withering tank. Enter the hot air for withering, the temperature of the hot air rises from 10°C to 30°C, and the temperature rising process lasts for 6 hours. After the temperature rises to 30°C, keep withering for 1 hour. The thickness of the fresh leaves laid in the withering tank is 2cm. When the fresh leaves Withering is completed when ...

Embodiment 2

[0040]The difference with Example 1 is that the first step is to pick the high mountain tea in May; in the second step, the cold air withering time at -3°C is 2 hours, and the temperature of the hot air withering rises to 30°C and keeps for 3 hours. The content of fresh leaves The withering is completed when the water volume is 60%; the fermentation time in the fourth step is 3 hours, and the fermentation temperature is 25°C; the hair fire is dried for 8 minutes in the fifth step; the temperature is controlled at 87°C in the seventh step, other conditions and implementation Same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com