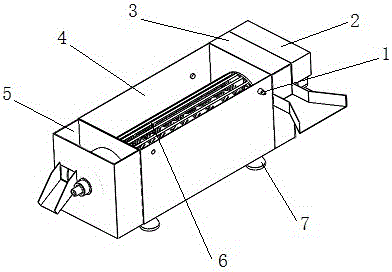

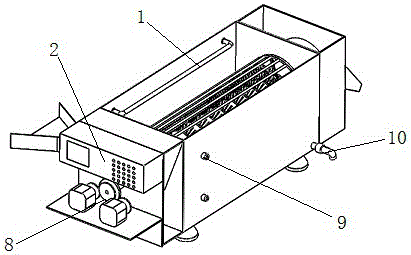

Automatic sweet potato washing machine (4)

A sweet potato, automatic technology, applied in the direction of non-electric variable control, food science, instruments, etc., can solve the problems of inability to realize automatic production, low production efficiency, damage to the skin structure of sweet potatoes, etc., to achieve water saving, high production efficiency, and no pollution environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

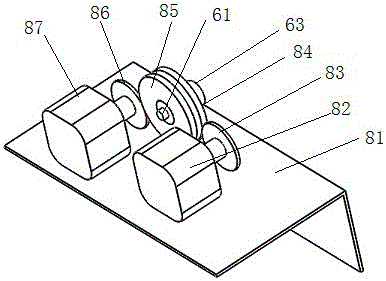

[0034] In order to further illustrate the technical scheme of the present invention, now in conjunction with accompanying drawing, illustrate the specific implementation manner of the present invention; Figure 10 , select the steel plate of thickness 8 millimeters for use in this example, choose its width identical with the width of feeding device 3 and weld it vertically into an angle iron shape, as mounting seat 81, install and fix holes on the vertical plate of mounting seat 81 , drive device installation elements are set on the plate; in this example, a commercially available motor and reducer integration are selected as the cage shaft drive device 82 and the brush shaft drive device 87, and they are respectively installed on the mounting base 81 on the cage shaft 63 In this example, the general gears used in this industry are selected as the cage shaft driving wheel 83, the cage shaft driving wheel 84, the brush shaft driving wheel 85 and the brush shaft driving wheel 86,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com