Four-wheel drive hub drive blade electric vehicle power assembly temperature integrated regulation and control system

A pure electric vehicle and powertrain technology, applied in electric vehicles, battery temperature control, electric power devices, etc., can solve problems such as the inability to guarantee the normal operation of the battery pack, improve work efficiency and service life, effectively utilize, realize energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

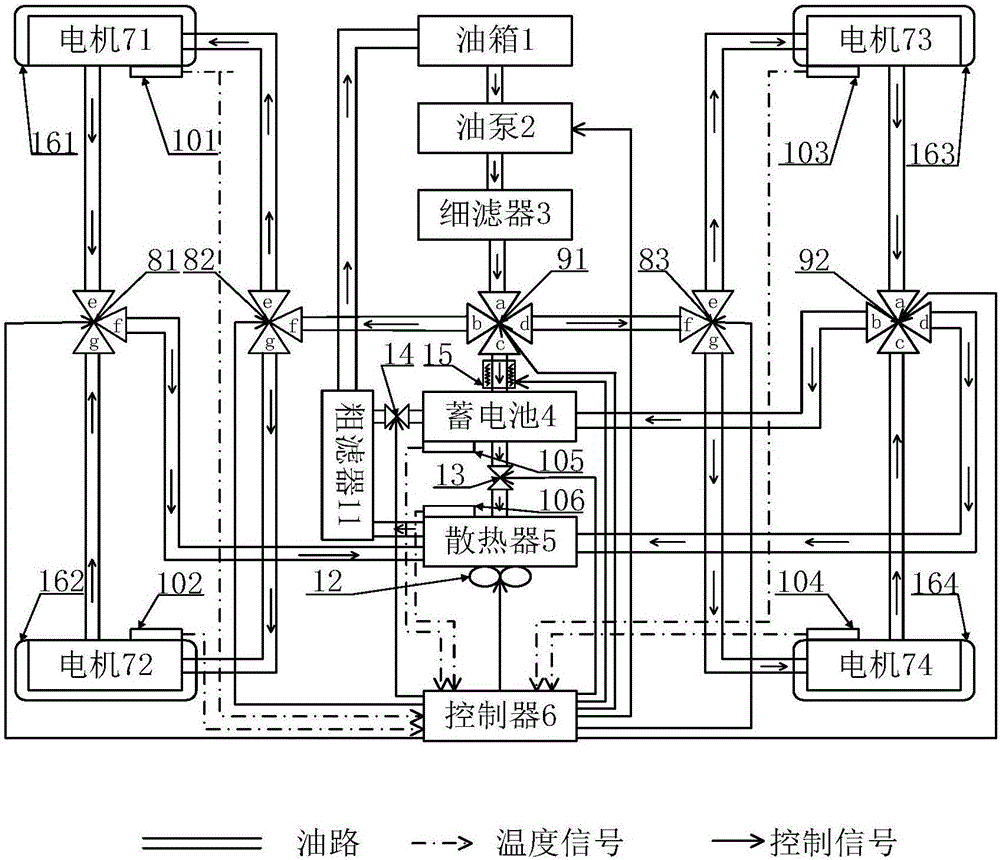

[0022] Such as figure 1 As shown, the four-wheel-drive hub-driven pure electric vehicle powertrain temperature integrated control system mainly consists of fuel tank 1, oil pump 2, fine filter 3, battery 4, radiator 5, controller 6, first hub motor 71, second hub Motor 72, third hub motor 73, fourth hub motor 74, first three-way valve 81, second three-way valve 82, third three-way valve 83, first four-way valve 91, second four-way valve 92, Temperature sensors 101, 102, 103, 104, 105 and 106, strainer 11, fan 12, first two-way valve 13, second two-way valve 14, heater 15 and wheels 161, 162, 163 and 164 and the like.

[0023] The oil pump 2 pumps the cooling oil from the oil tank 1 into the fine filter 3, and the cooling oil flows in through the valve port of the first four-way valve 91 and then divides into three branches, one of which flows through the second three-way valve 82 and then flows to the first hub motor 71 respectively. and the second wheel hub motor 72, then fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com