Self-excitation type retarder adopting double-rotor structure and control method of self-excitation type retarder

A retarder, double rotor technology, applied in electric braking systems, electric vehicles, transportation and packaging, etc., can solve the problem that the retarder braking torque is not adjustable, cannot fully utilize the dual rotor disc, cannot Generate braking torque and other problems to achieve the effect of solving thermal recession, continuous braking force, and expanding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

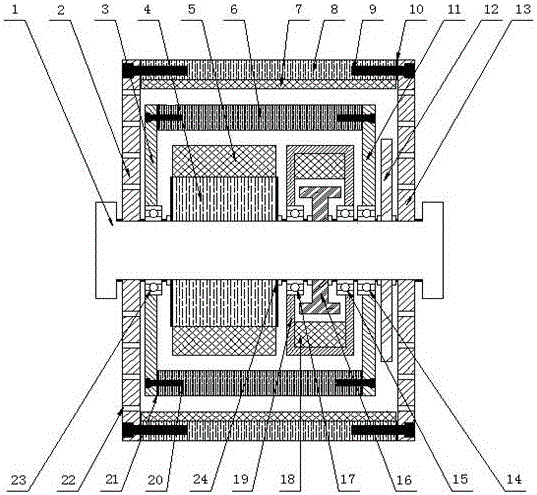

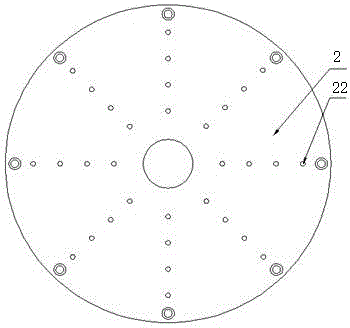

[0024] see figure 1 The self-excited retarder of the present invention has a transmission shaft 1, a left side housing 2 and a right side housing 13, and the left side housing 2 and the right side housing 13 are respectively coaxially sleeved on the left end and the right end of the transmission shaft 1 , and is fixedly connected with the transmission shaft 1. Between the radially outer edges of the left casing 2 and the right casing 13 , the outer rotor 8 is fixedly connected by first screws 9 . Salient poles are arranged on the inner side of the outer rotor 8 . The salient poles are arranged radially inward, and the outer rotor excitation coils 7 are wound on the salient poles. An outer rotor magnetic plate 10 is respectively connected between the left and right ends of the outer rotor 8 and the left casing 2 and the right casing 13 .

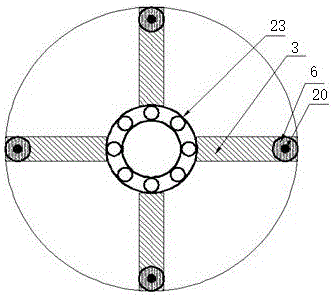

[0025] A left stator support 3 and a right stator support 11 are also arranged between the left housing 2 and the right housing 13, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com