Folding type transmission equipment for unloading barreled water

A transmission equipment and a folding technology, applied in the field of folding transmission equipment, can solve the problems of difficulty in unloading bottled water, waste of time, waste of physical strength, etc., and achieve the effects of simple structure, easy portability, and high space utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

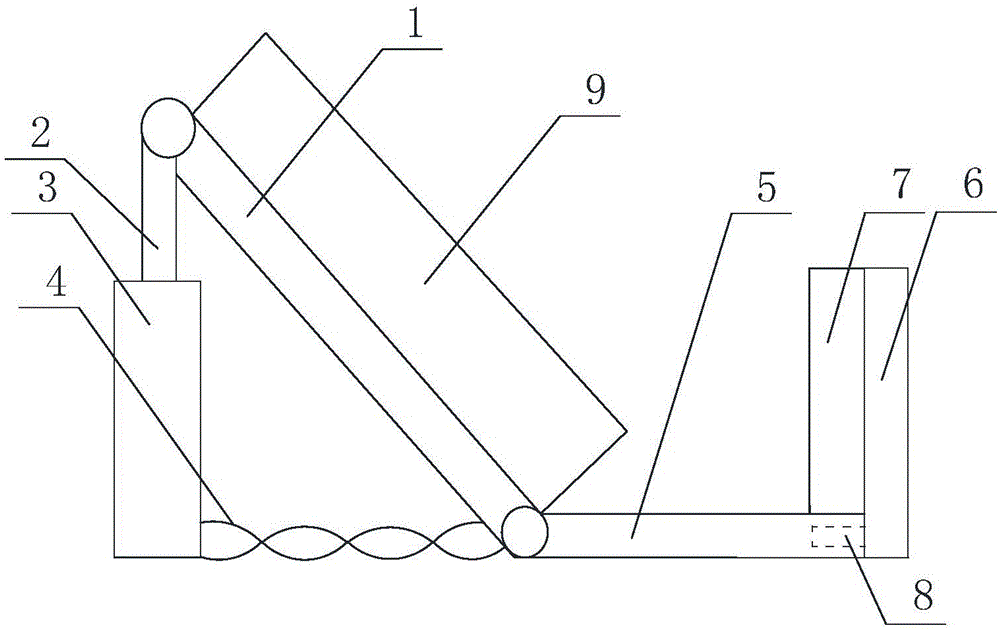

[0022] Such as figure 1 As shown, a folding transmission device for unloading bottled water in the present invention includes a slide plate 1 connected to a telescopic column, and the telescopic column includes a thin rod 2 connected to the upper end of the slide plate 1, and the thin rod 2 is connected to the upper end of the slide plate 1. The skateboard 1 is linked by a hinge, the other end of the thin rod 2 is sleeved in the sleeve rod 3, and the lower end of the sleeve rod 3 and the skateboard 1 is connected by a chain 4. The telescopic column is perpendicular to the ground and an inclination angle is formed between the telescopic column and the skateboard 1. The lower end of the slide plate 1 is also connected with an anti-friction plate 5, one end of the anti-friction plate 5 is linked with the slide plate 1 through a hinge, and the other end of the anti-friction plate 5 is equipped with a first baffle plate 6. Both sides of the slide plate 1 are provided with second ba...

Embodiment 2

[0025] Based on Embodiment 1, an air bag 7 is installed on one surface of the anti-friction board 5 , and the air bag 7 is located between the anti-friction board 5 and the slide plate 1 . When installing the device, fill the inert gas inside the inflatable bag. After the inflatable bag is filled with gas, it can provide a buffer for the falling bottled water; it also prevents the bottled water from sliding down from a high place quickly, and will continue to move forward due to inertia roll. If the cost is not considered, the inflatable bag is connected to an electronic gas generator, the gas generator is connected to the pressure sensor, and the pressure sensor is located on the anti-friction plate. Once the bucket water rolls on the anti-friction plate, the pressure sensor detects the pressure and will control The gas generator is turned on, and then the gas generator charges the inflatable bag. This method does not require manual inflation, and the inflation speed is fast....

Embodiment 3

[0027] Based on the above-mentioned embodiment, a bolt A is connected to one side wall of the sleeve rod 3, and a bolt B is connected to the other side wall of the sleeve rod 3, and the bolt A and the bolt B are mirror-image symmetric with respect to the sleeve rod 3, and the bolts Both A and bolt B pass through the sleeve rod 3 to the inside of the sleeve rod 3, and the bolt A and the bolt B cooperate to fasten the thin rod 2. The telescopic principle of the telescopic rod is: loosen bolt A and bolt B in advance, adjust the length of the thin rod by observing the height of the truck, the lower part of the thin rod can move up and down inside the sleeve rod, when the thin rod is adjusted to a suitable position, Tighten bolt A and bolt B at the same time to fix the thin rod and the sleeve rod. The present invention adopts the telescopic rod of this embodiment, which has low cost, simple adjustment method and convenient use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com