Separating method for collagen antifreeze peptide

A separation method, collagen technology, applied in the field of bioengineering, can solve problems such as difficult to achieve rapid, high-throughput screening, cumbersome and time-consuming screening process, and achieve the effect of low cost and simple separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

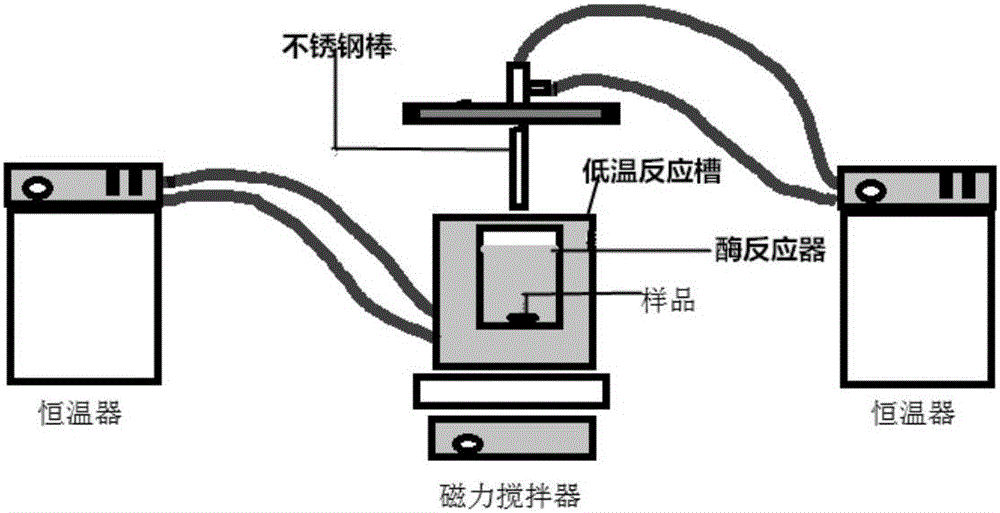

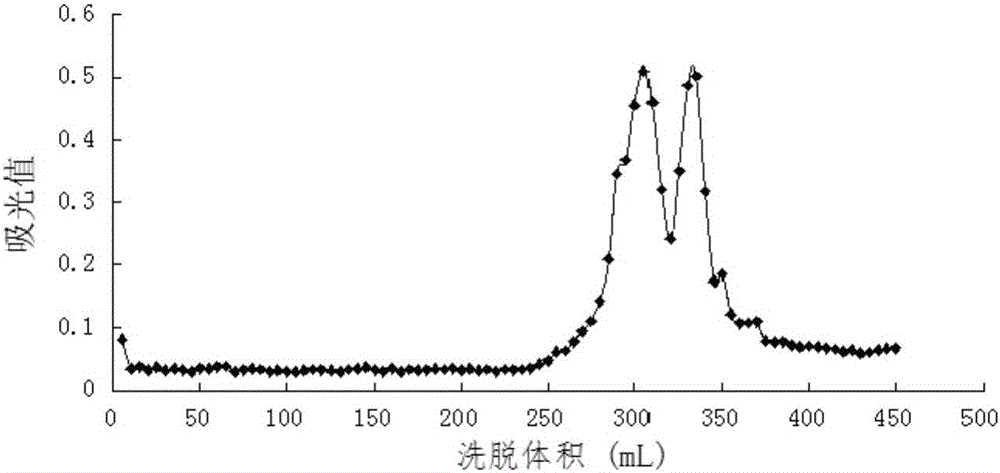

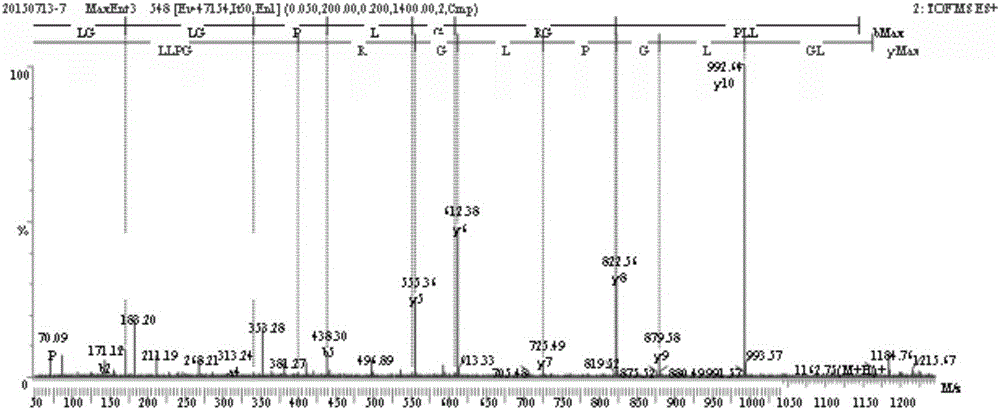

[0030] A preparation method of collagen antifreeze peptide, specifically comprising the steps of:

[0031] (1), preparation of collagen

[0032] ①. Use scissors to remove the hair on the surface of the pigskin, wash it with distilled water, and store it at -20°C for later use.

[0033] ②. Cut the pigskin after ① into pieces (0.5mm×0.5mm), degrease with 10% butanol solution prepared with 10 times the volume of double distilled water for 24 hours, change the butanol solution every 12 hours, and then wash it with distilled water .

[0034] ③. Soak degreased pigskin in 0.5M acetic acid solution prepared with double distilled water for 12 hours, and homogenate with 10 times the volume of the same solution; add (w / v) pepsin dissolved in 1% double distilled water to the homogenate (1200U / g), hydrolyzed at 4°C for 48h, centrifuged (5000g, 40min) after hydrolysis, and collected the supernatant; adding NaCl powder to the supernatant for salting out (to make the final concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com