Electrolytic reaction device for preparing graphene

An electrolytic reaction and graphene technology, applied in the field of graphene, can solve the problems such as graphene cannot be automated, and achieve the effects of reducing the preparation cost and preparation difficulty, being easy to replace, and having a low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

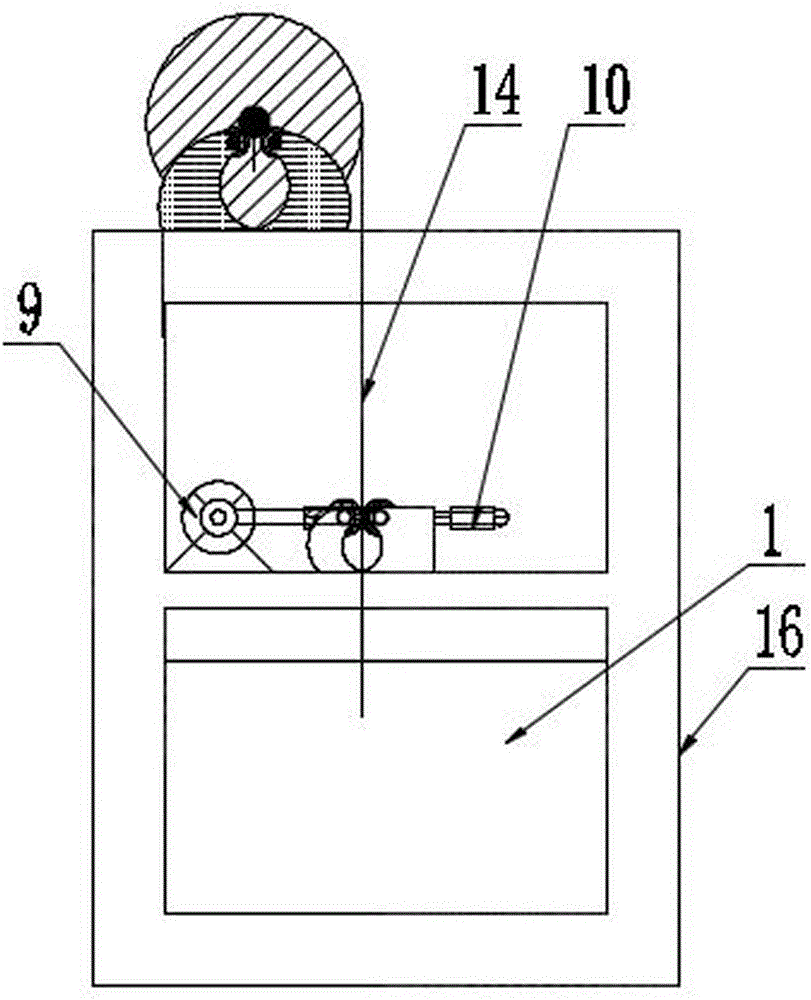

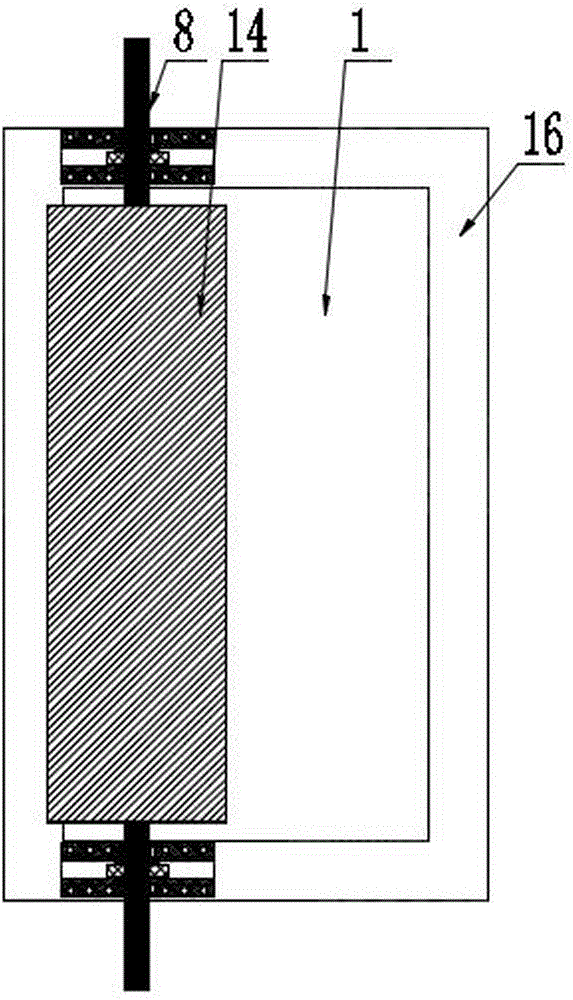

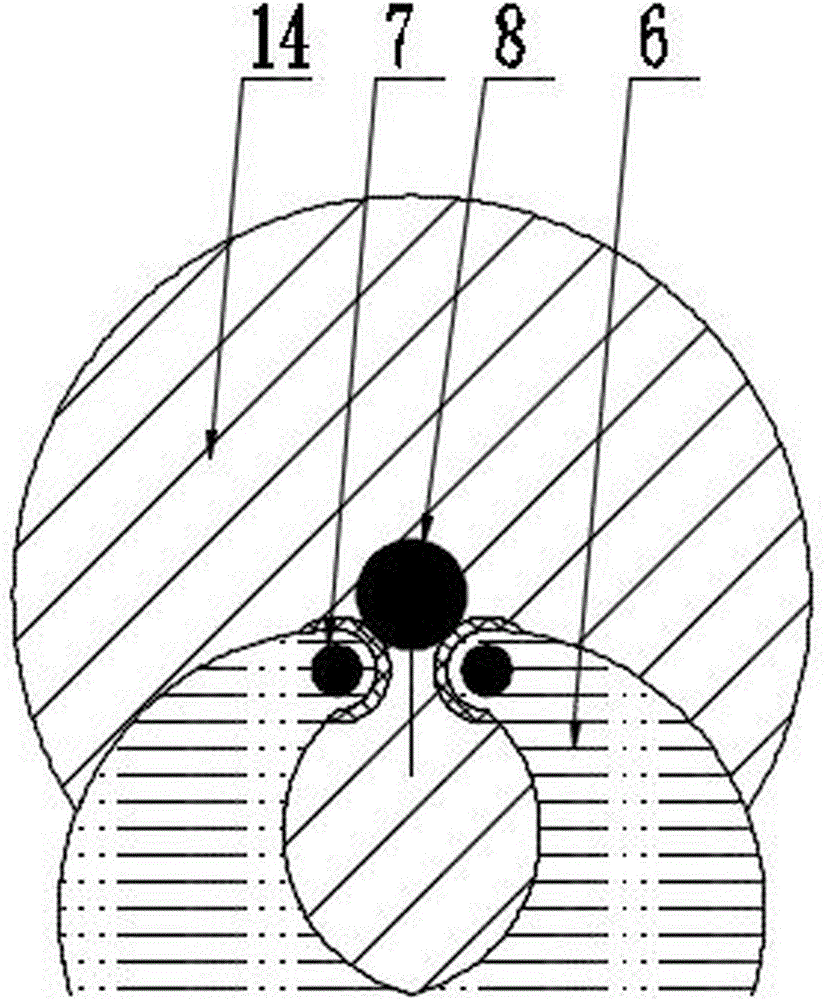

[0033] An electrolytic reaction device for preparing graphene, comprising an electrolytic cell 1, a motor 9, a graphite plate, a blanking mechanism and a graphite paper support mechanism, the blanking mechanism includes a pressing roller 3, a pressing cylinder 10 and a carbon brush 4 The graphite conductive roller 5 connected to the positive stage of the power supply, the pressing roller 3 and the graphite conductive roller 5 are symmetrically arranged above the electrolytic cell 1, the graphite conductive roller 5 is connected with the motor 9 through a belt 15, and the pressing cylinder 10 Connected with the pinch roller 3, it is used to adjust the distance between the graphite conductive roller 5 and the pinch roller 3, so as to realize the smooth unloading of the graphite paper 14; the graphite paper supporting mechanism is fixed above the unloading mechanism for supporting the winding Graphite paper 14; the graphite plate is connected to the negative pole of the power supp...

Embodiment 2

[0046]An electrolytic reaction device for preparing graphene, comprising an electrolytic cell 1, a motor 9, a graphite plate, a blanking mechanism and a graphite paper support mechanism, the blanking mechanism includes a pressing roller 3, a pressing cylinder 10 and a carbon brush 4 The graphite conductive roller 5 connected to the positive stage of the power supply, the pressing roller 3 and the graphite conductive roller 5 are symmetrically arranged above the electrolytic cell 1, the graphite conductive roller 5 is connected with the motor 9 through a belt 15, and the pressing cylinder 10 Connected with the pinch roller 3, it is used to adjust the distance between the graphite conductive roller 5 and the pinch roller 3, so as to realize the smooth blanking of the graphite paper 14; the graphite paper support mechanism is fixed above the blanking mechanism for supporting the graphite paper roll; the graphite plate is connected to the negative pole of the power supply through a...

Embodiment 3

[0049] An electrolytic reaction device for preparing graphene, comprising an electrolytic cell 1, a motor 9, a graphite plate, a blanking mechanism and a graphite paper support mechanism, the blanking mechanism includes a pressing roller 3, a pressing cylinder 10 and a carbon brush 4 The graphite conductive roller 5 connected to the positive stage of the power supply, the pressing roller 3 and the graphite conductive roller 5 are symmetrically arranged above the electrolytic cell 1, the graphite conductive roller 5 is connected with the motor 9 through a belt 15, and the pressing cylinder 10 Connected with the pinch roller 3, it is used to adjust the distance between the graphite conductive roller 5 and the pinch roller 3, so as to realize the smooth blanking of the graphite paper 14; the graphite paper support mechanism is fixed above the blanking mechanism for supporting the graphite paper roll; the graphite plate is connected to the negative pole of the power supply through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com