A kind of dyeing auxiliary agent for supercritical carbon dioxide cotton fiber dyeing and its preparation and application

A technology of dyeing auxiliaries and carbon dioxide, which is applied in the field of cotton fiber dyeing, can solve the problems of cotton fiber dyeing difficulties, achieve remarkable economic and environmental benefits, high color fastness, and high color depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

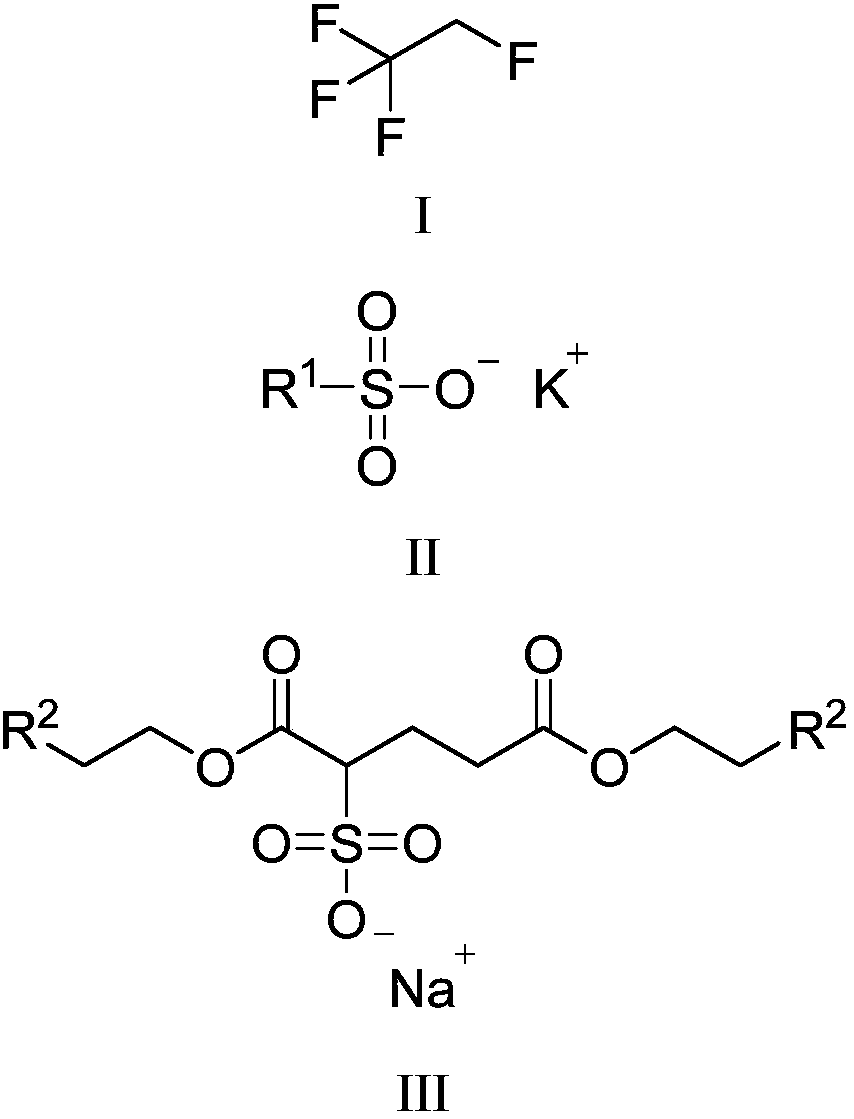

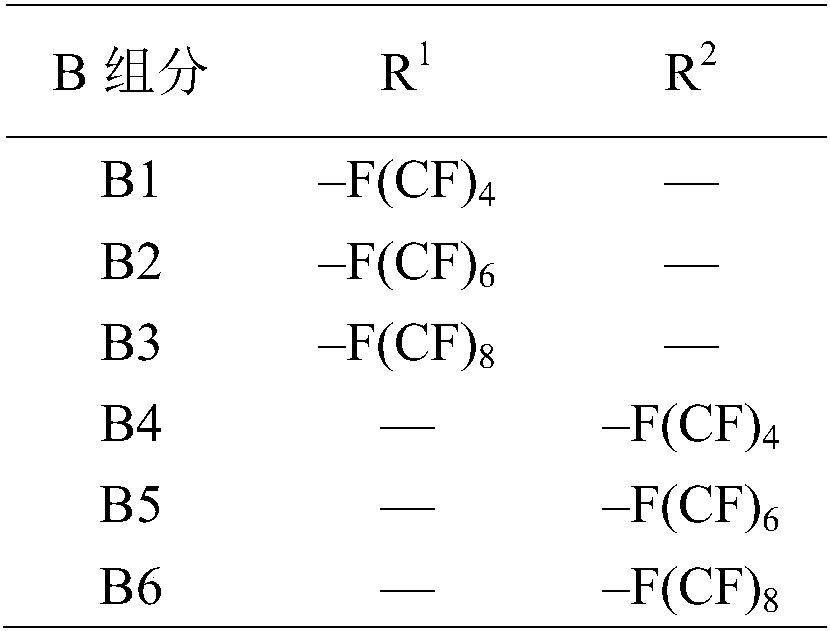

Method used

Image

Examples

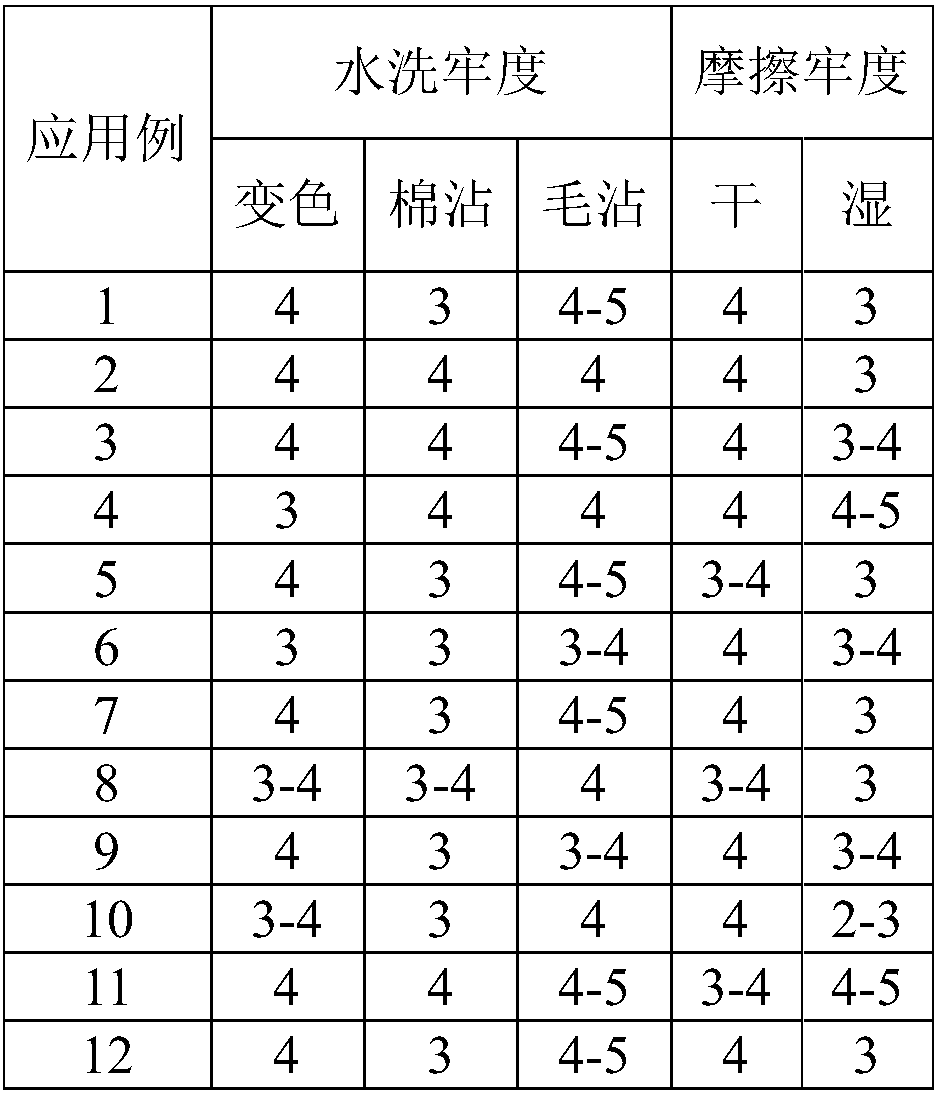

Embodiment 1

[0038] 1g curcumin is pulverized in 80 mesh fineness pulverizers, then puts in the dye kettle of supercritical carbon dioxide dyeing device (flow process is as shown in Fig. 1 in reference 1), the B in cotton loose fiber and dyeing auxiliary agent Put the components into the dyeing kettle, close the dyeing kettle, fill supercritical carbon dioxide into the supercritical dyeing device, heat up to make the system temperature 140°C, open the high-pressure system to make the pressure 25Mpa, and pass the auxiliary agent pump under this condition Fill the system with component A, wherein the dyeing auxiliaries are composed of 55% component A and 45% component B (component B is 100% B1), and the dyeing time is 120min; then release the pressure to 4Mpa, at 40 Carbon dioxide and dyes are recovered at ℃; the pressure is released, the temperature is lowered to normal, and the dyeing kettle is opened to obtain dyed cotton fibers. The dyed cotton fibers were washed with acetone, and then w...

Embodiment 2

[0040]1g curcumin is pulverized in 80 mesh fineness pulverizers, then puts in the dye kettle of supercritical carbon dioxide dyeing device (flow process is as shown in Fig. 1 in reference 1), the B in cotton loose fiber and dyeing auxiliary agent Put the components into the dyeing kettle, close the dyeing kettle, fill supercritical carbon dioxide into the supercritical dyeing device, heat up to make the system temperature 140°C, open the high-pressure system to make the pressure 25Mpa, and pass the auxiliary agent pump under this condition Fill the A component like the system, wherein, the dyeing auxiliaries are composed of 55% A component and 45% B component (B component is 100% B2), and the dyeing time is 120min; then release the pressure to 4Mpa, at 40 Carbon dioxide and dyes are recovered at ℃; the pressure is released, the temperature is lowered to normal, and the dyeing kettle is opened to obtain dyed cotton fibers. The dyed cotton fibers were washed with acetone, and th...

Embodiment 3

[0042] 1g curcumin is pulverized in 80 mesh fineness pulverizers, then puts in the dye kettle of supercritical carbon dioxide dyeing device (flow process is as shown in Fig. 1 in reference 1), the B in cotton loose fiber and dyeing auxiliary agent Put the components into the dyeing kettle, close the dyeing kettle, fill supercritical carbon dioxide into the supercritical dyeing device, heat up to make the system temperature 140°C, open the high-pressure system to make the pressure 25Mpa, and pass the auxiliary agent pump under this condition Fill the A component like the system, wherein, the dyeing auxiliaries are composed of 55% A component and 45% B component (B component is 100% B3), and the dyeing time is 120min; then release the pressure to 4Mpa, at 40 Carbon dioxide and dyes are recovered at ℃; the pressure is released, the temperature is lowered to normal, and the dyeing kettle is opened to obtain dyed cotton fibers. The dyed cotton fibers were washed with acetone, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com