A cold pad-batch process for preparing gray-black pure linen fabric

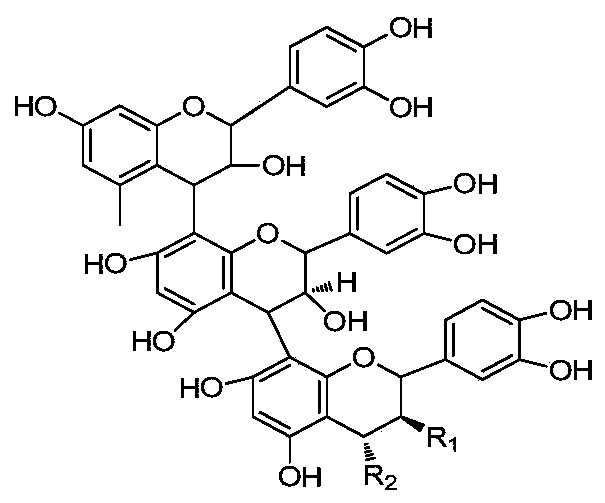

A flax fabric and cold-rolled stacking technology, which is applied in the field of fabric dyeing, can solve the problems of complex preparation process and difficult mass production of gray-black pure linen fabric, and achieve the effects of improving permeability, prolonging contact time, and cumbersome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

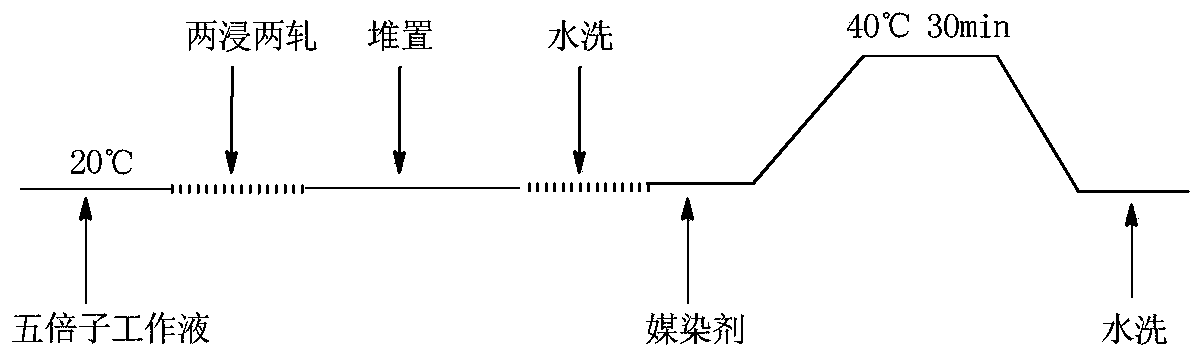

[0029] Preparation of gray-black pure linen fabric by cold-pile process:

[0030] (1) cold pad batch process

[0031] The o.w.f of Galla gall natural dye is 2%, the bath ratio is 1:20, dipped twice and rolled twice at 20°C, stacked for 10 hours, washed with water, and set aside;

[0032] (2) Post-mordanting process

[0033] HAc 2g / L, ferrous sulfate 5g / L, liquor ratio 1:30, constant temperature at 40°C for 30min; washing with water, soaping, and drying to obtain gray-black pure linen fabric.

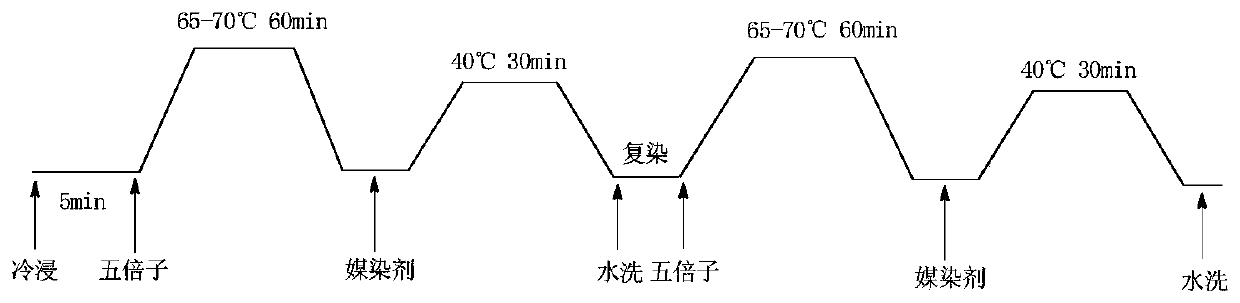

[0034] Preparation of gray-black pure linen fabric by high temperature dyeing process:

[0035] (1) dyeing process

[0036] The o.w.f of Galla gall natural dye is 2%, the bath ratio is 1:20, dyed at 60°C for 60min, washed with water, and set aside;

[0037] (2) Post-mordanting process

[0038] HAc 2g / L, ferrous sulfate 5g / L, bath ratio 1:30, constant temperature at 40°C for 30min; wash with water, set aside;

[0039] (3) Counter-staining process

[0040] After repeating steps (1) ...

Embodiment 2

[0042] Preparation of gray-black pure linen fabric by cold-pile process:

[0043] (1) cold pad batch process

[0044] The o.w.f of Galla gall natural dye is 4%, the bath ratio is 1:20, dipped twice and rolled twice at 20°C, stacked for 10 hours, washed with water, and set aside;

[0045] (2) Post-mordanting process

[0046] HAc 2g / L, ferrous sulfate 5g / L, liquor ratio 1:30, constant temperature at 40°C for 30min; washing with water, soaping, and drying to obtain gray-black pure linen fabric.

[0047] Preparation of gray-black pure linen fabric by high temperature dyeing process:

[0048] (1) dyeing process

[0049] The o.w.f of Galla gall natural dye is 4%, the bath ratio is 1:20, dyed at 60°C for 60 minutes, washed with water, and set aside;

[0050] (2) Post-mordanting process

[0051] HAc 2g / L, ferrous sulfate 5g / L, bath ratio 1:30, constant temperature at 40°C for 30min; wash with water, set aside;

[0052] (3) Counter-staining process

[0053] After repeating steps...

Embodiment 3

[0055] Preparation of gray-black pure linen fabric by cold-pile process:

[0056] (1) cold pad batch process

[0057] The o.w.f of gallnut natural dye is 6%, the bath ratio is 1:20, it is dipped and rolled twice at 20°C, stacked for 10 hours, washed with water, and set aside;

[0058] (2) Post-mordanting process

[0059] HAc 2g / L, ferrous sulfate 5g / L, liquor ratio 1:30, constant temperature at 40°C for 30min; washing with water, soaping, and drying to obtain gray-black pure linen fabric.

[0060] Preparation of gray-black pure linen fabric by high temperature dyeing process:

[0061] (1) dyeing process

[0062] The o.w.f of Galla gall natural dye is 6%, the bath ratio is 1:20, dyed at 60°C for 60min, washed with water, and set aside;

[0063] (2) Post-mordanting process

[0064] HAc 2g / L, ferrous sulfate 5g / L, bath ratio 1:30, constant temperature at 40°C for 30min; wash with water, set aside;

[0065] (3) Counter-staining process

[0066] After repeating steps (1) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com