Coated paper and production method thereof

A technology for coated paper and pulp, applied in the field of papermaking, can solve the problems of low strength, excessive ash content and poor air permeability of coated paper, and achieve the effects of high quality, excellent quality and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

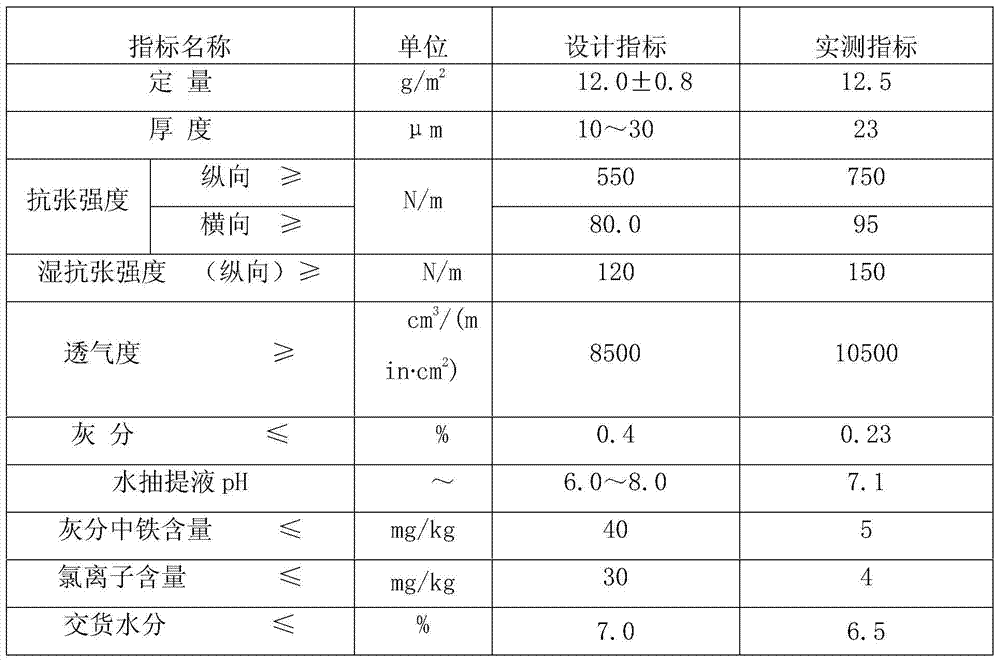

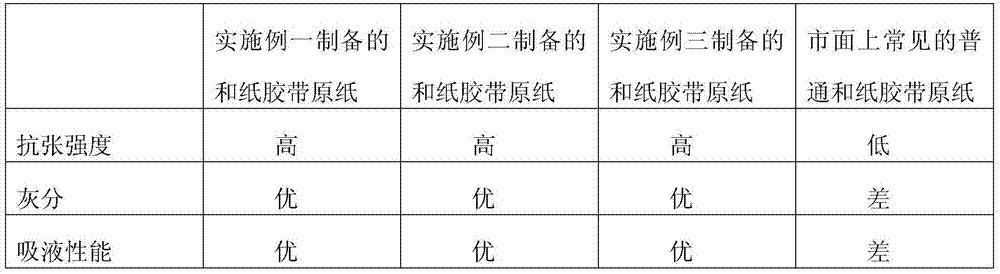

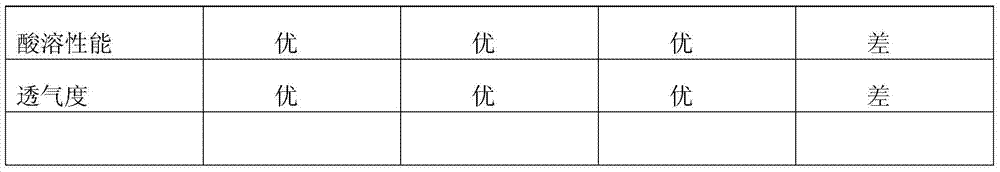

Examples

Embodiment 1

[0028] The coated board paper is made of the following raw material proportions by weight: 45 parts of long-fiber wood pulp, 25 parts of hemp pulp, 10 parts of chemical fiber, 1 part of wet strength agent, and 0.2 part of PEO dispersant.

[0029] Further, the long-fiber wood pulp is coniferous wood pulp, and is thick long-fiber wood pulp in coniferous wood.

[0030] Further, hemp pulp is Manila hemp pulp.

[0031] Further, the chemical fibers are viscose fibers.

[0032] Further, the wet strength agent is polyester amide.

[0033] Further, the PEO dispersant is polyoxyethylene.

[0034] Further, the above-mentioned production method of coated paper comprises the following steps:

[0035] The first step is raw water treatment. Tap water is first filtered twice with a sand filter, then filtered for the third time with a honeycomb filter, and then purified by a reverse osmosis water purifier to obtain raw water. At this time, the COD index of the raw water is 12 ;

[0036] T...

Embodiment 2

[0041] The coated board paper is made of the following raw material proportions by weight: 55 parts of long-fiber wood pulp, 30 parts of hemp pulp, 15 parts of chemical fiber, 2 parts of wet strength agent, and 0.5 part of PEO dispersant.

[0042] Further, the long-fiber wood pulp is coniferous wood pulp, and is thick long-fiber wood pulp in coniferous wood.

[0043] Further, hemp pulp is Manila hemp pulp.

[0044] Further, the chemical fibers are viscose fibers.

[0045] Further, the wet strength agent is polyester amide.

[0046] Further, the PEO dispersant is polyoxyethylene.

[0047] Further, the above-mentioned production method of coated paper comprises the following steps:

[0048] The first step is raw water treatment. Tap water is first filtered twice with a sand filter, then filtered for the third time with a honeycomb filter, and then purified by a reverse osmosis water purifier to obtain raw water. At this time, the COD index of the raw water is 13 ;

[0049] ...

Embodiment 3

[0054] The coated paper is made of the following raw material proportions by weight: 60 parts of long-fiber wood pulp, 35 parts of hemp pulp, 20 parts of chemical fiber, 3 parts of wet strength agent, and 0.8 part of PEO dispersant.

[0055] Further, the long-fiber wood pulp is coniferous wood pulp, and is thick long-fiber wood pulp in coniferous wood.

[0056] Further, hemp pulp is Manila hemp pulp.

[0057] Further, the chemical fibers are viscose fibers.

[0058] Further, the wet strength agent is polyester amide.

[0059] Further, the PEO dispersant is polyoxyethylene.

[0060] Further, the above-mentioned production method of coated paper comprises the following steps:

[0061] The first step is raw water treatment. Tap water is first filtered twice with a sand filter, then filtered for the third time with a honeycomb filter, and then purified by a reverse osmosis water purifier to obtain raw water. At this time, the COD index of the raw water is 15 ;

[0062] The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com