Gradation method of small-grain-size skeleton dense type asphalt mixture

A technology of asphalt mixture and small particle size, which can be applied to roads, on-site cohesive pavements, road repairs, etc. It can solve the problems that it is difficult to meet the requirements of road performance and anti-skid performance, and it is unreasonable to ensure that Road performance and durability, and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the drawings.

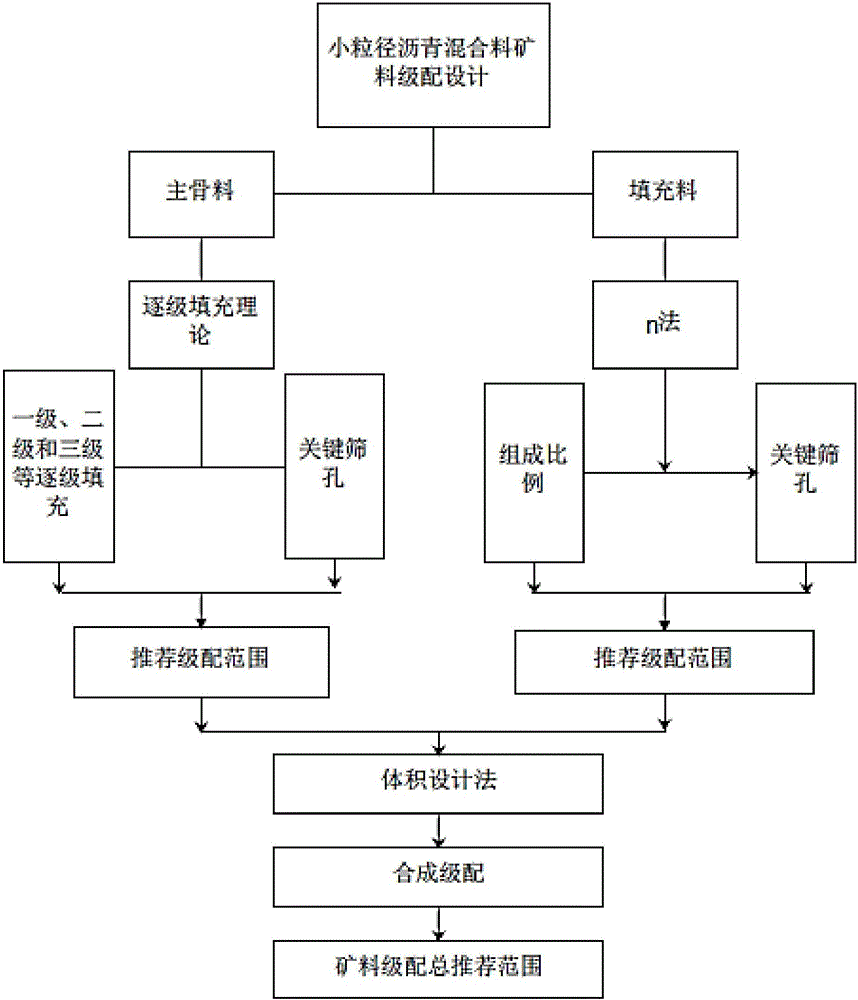

[0041] See figure 1 , The method for grading small particle size skeleton dense asphalt mixture of the present invention includes the following steps:

[0042] (1) Defining the main aggregate and filler: adopting the conclusions of Bailey method and related research to dynamically divide the boundary between the main aggregate and the filler aggregate in the small particle size skeleton dense asphalt mixture. The boundary point of the coarse and fine aggregate of the asphalt mixture changes with the change of the nominal maximum particle size of the aggregate. The boundary sieve opening of the coarse and fine aggregate is determined by 0.22 times the nominal maximum particle size.

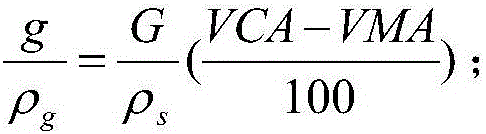

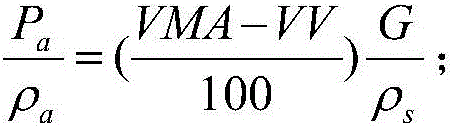

[0043] (2) Design of the main aggregate composition: Based on the gradual filling theory, determine the coarse aggregate clearance ratio VCA, California bearing ratio CBR and maximum bearing capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com