Hydraulic model test water surface profile and flow velocity measuring device and method

A hydraulic model and flow velocity measurement technology, applied in the field of measurement, can solve problems such as inaccurate depth control, and achieve the effects of reducing manpower input, increasing accuracy, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

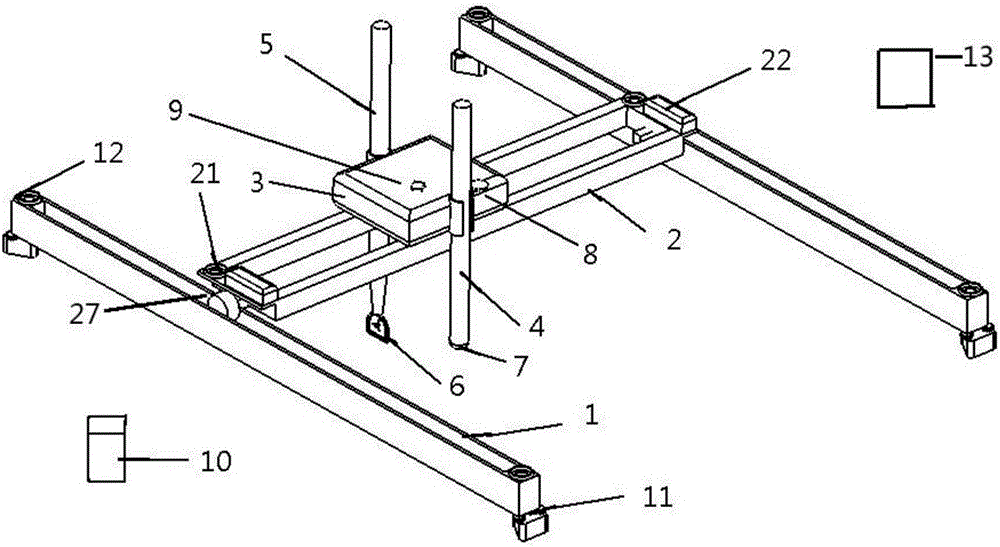

[0042] In order to enable the present invention to achieve its due actual effects, further description will be given below in conjunction with the accompanying drawings.

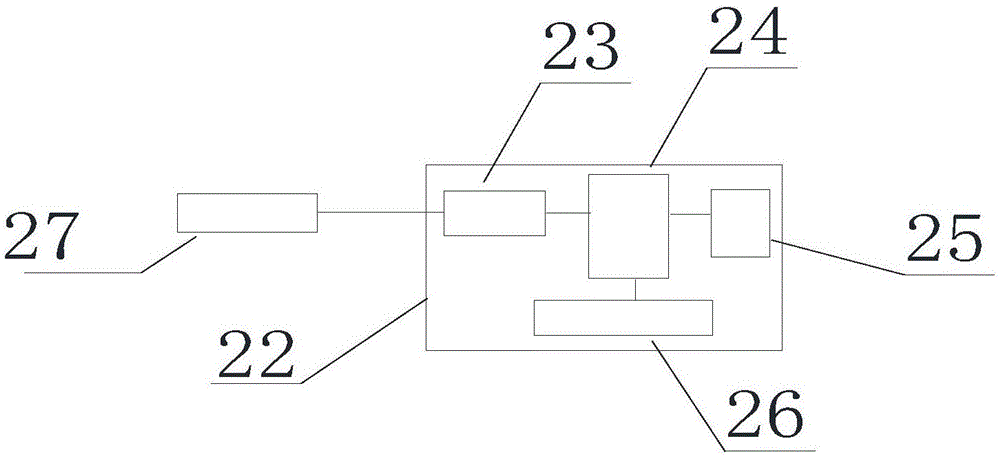

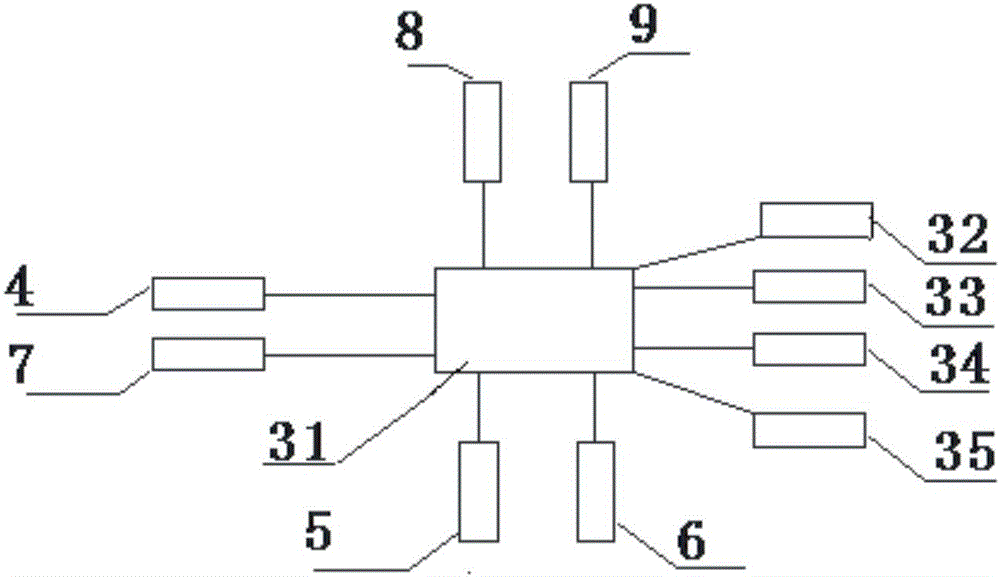

[0043] Such as Figure 1-7 As shown, a hydraulic model test water surface line and flow velocity measuring device includes two horizontally arranged fixed guide rails 1, on which two fixed guide rails 1 are provided with a vertical and movable back and forth. The movable guide rail 2 is provided with a movable measuring device 3 on the movable guide rail. The movable measuring rod I 4 and the movable measuring rod II 5 are vertically arranged on the outer side of the movable measuring device 3. The bottom of I 4 is provided with a touch switch 7, and the bottom of the movable measuring rod II5 is provided with a propeller flow meter 6; the probe of the laser rangefinder 8 extends out of the mobile measuring device, and the probe is fixed on the side wall of the mobile measuring device , Used to detect the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com