Suspension type comprehensive pipe gallery and maintenance platform system

A comprehensive pipe gallery and hanging technology, applied in industrial buildings and other directions, can solve the problems of high operating costs, rough installation process, damage to the anti-corrosion coating on the surface of buildings, etc., to achieve widespread application value, shorten construction period, and facilitate theoretical effect of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

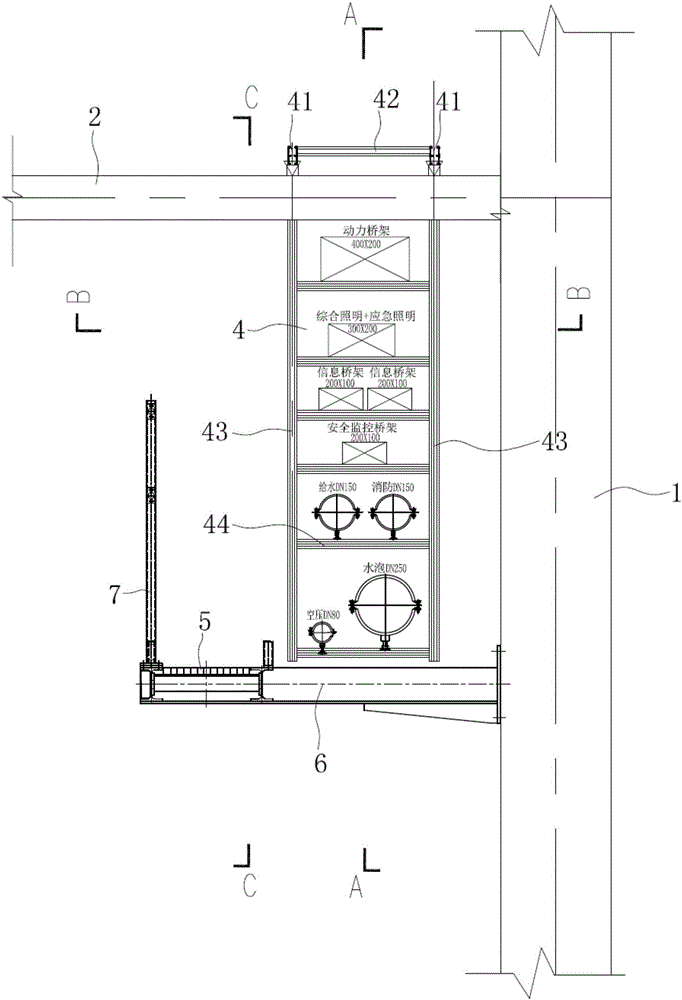

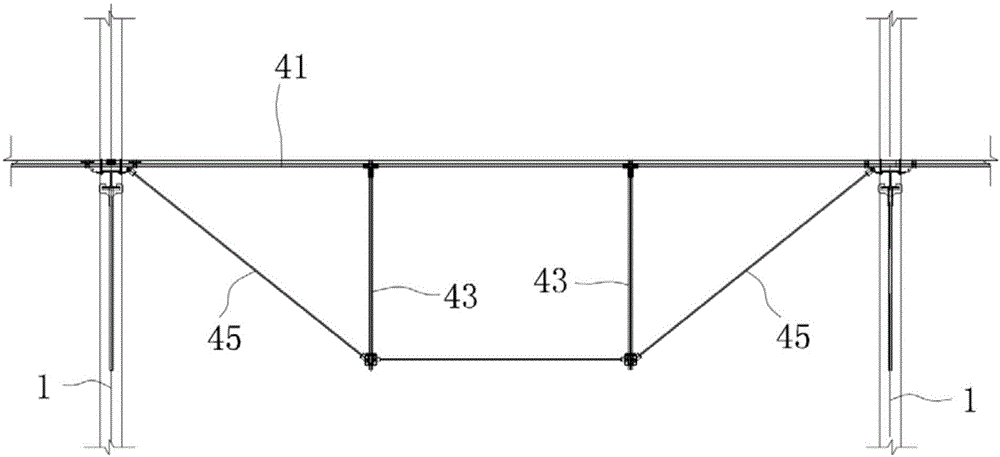

[0037] Attached below Figure 1-9 The technical solutions of the present invention are further described through specific implementation methods.

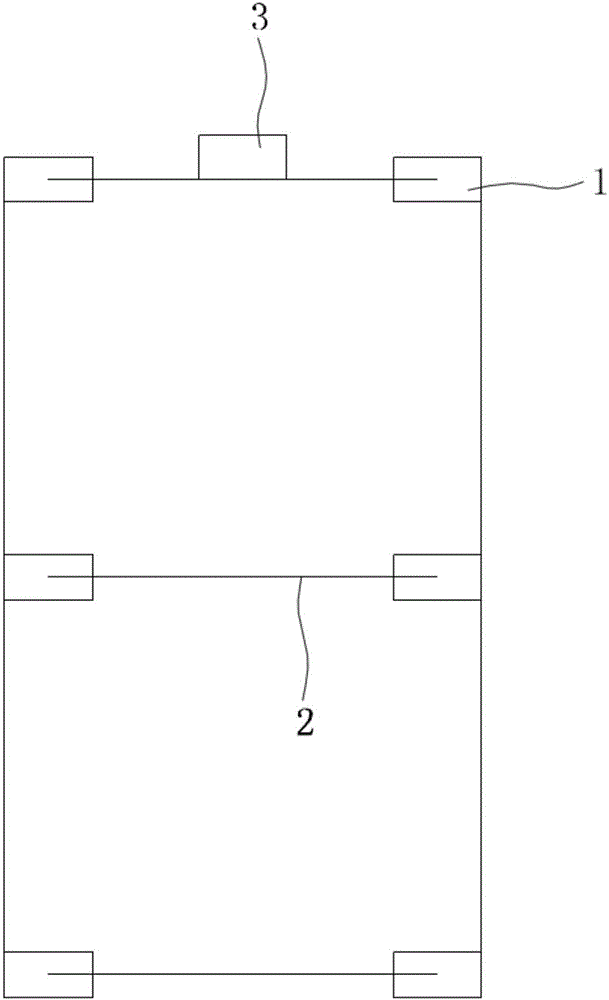

[0038] Such as figure 1 As shown, it is a schematic diagram of the distribution structure of the columns, beams and wind-resistant columns in the house; in this embodiment, it is a schematic diagram of the distribution structure inside the garage of the bullet train station. It has two rows of uprights 1 , each row comprising a plurality of uprights 1 . A crossbeam 2 is built between two columns 1 in the same row in the two rows of columns. Wind-resistant columns 3 are arranged at the ends of the two rows of uprights, and the wind-resistant columns 3 are located between the two uprights at the ends and outside the beams 2 . Hereinafter, based on such a house structure, the suspended integrated pipe gallery and maintenance platform system of the present invention will be further described.

[0039] A suspended integrated pipe ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com