Hydrophobicity detection method of power transmission line vulcanized silicone rubber coating

A technology of vulcanized silicone rubber and transmission lines, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve the problem of high lift requirements for drones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

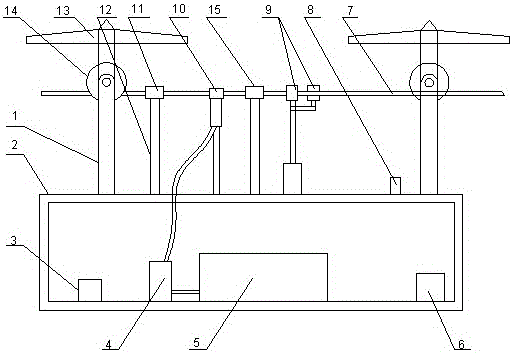

[0036] The method for testing the hydrophobicity of vulcanized silicone rubber coatings on transmission lines, the steps are as follows:

[0037] S1: Adopt a suspended detection device with a traveling mechanism 14, use a multi-rotor aircraft to lift it to the line 7 to be tested, and control it to hang on the line 7 through the remote control of the operator;

[0038] S2: After hanging on the line 7, the multi-rotor aircraft stops working to save energy consumption, and drives the device to walk on the line through the traveling mechanism 14;

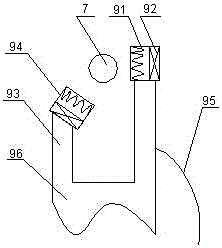

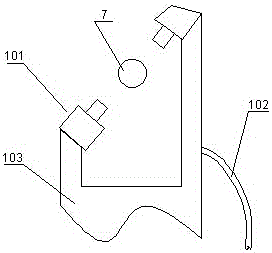

[0039] S3: Walk directly on the line 7 through this device, and collect and analyze the actual condition of the line through the front image acquisition module 8 set on it. If condensation occurs on the line 7, use the drying mechanism 9 on the line 7 dry to ensure the accuracy of detection after the water spray mechanism 10 sprays water;

[0040] S4: after drying, image acquisition is carried out by the middle image acquisition modul...

Embodiment 3

[0057] It differs from the second embodiment in that: the automatic telescopic rod 23 is an electric telescopic rod.

[0058] In this embodiment, a center-of-gravity adjustment module is provided at the bottom of the frame to adjust the center of gravity of the trolley, so as to avoid the instability of the center of gravity from affecting the work of the trolley; The position of the block can be used to adjust the center of gravity; the automatic telescopic rod adopts an electric telescopic rod, which has the advantages of small size and easy control.

Embodiment 4

[0060] The difference between it and Embodiment 3 is that: the upper part of the water tank 5 is provided with a water inlet, and the water inlet is connected with a water pipe 16, and the lower end of the water pipe 16 is connected with a quick joint 17, and the quick joint 17 is used to connect to the water tank on the ground. A water pump to fill the tank with water.

[0061] In this embodiment, a water inlet is provided on the upper part of the water tank, and the water inlet is connected with a water pipe, and the lower end of the water pipe is connected to the water pump on the ground through a quick joint, so that the water tank can be filled through the water pipe as required, thereby increasing the online operation of the device Time; The water-repellent agent that adopts in this embodiment pressurizes the storage tank by an air pump, then the water-repellent agent in the material storage tank is delivered to the spray nozzle through the paint pipe of its bottom, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com