Semiconductor device

A semiconductor and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of reducing the reliability of source electrodes and bus electrodes, and achieve the effect of inhibiting corrosion and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Next, a semiconductor device 1 as an embodiment of the present invention will be described.

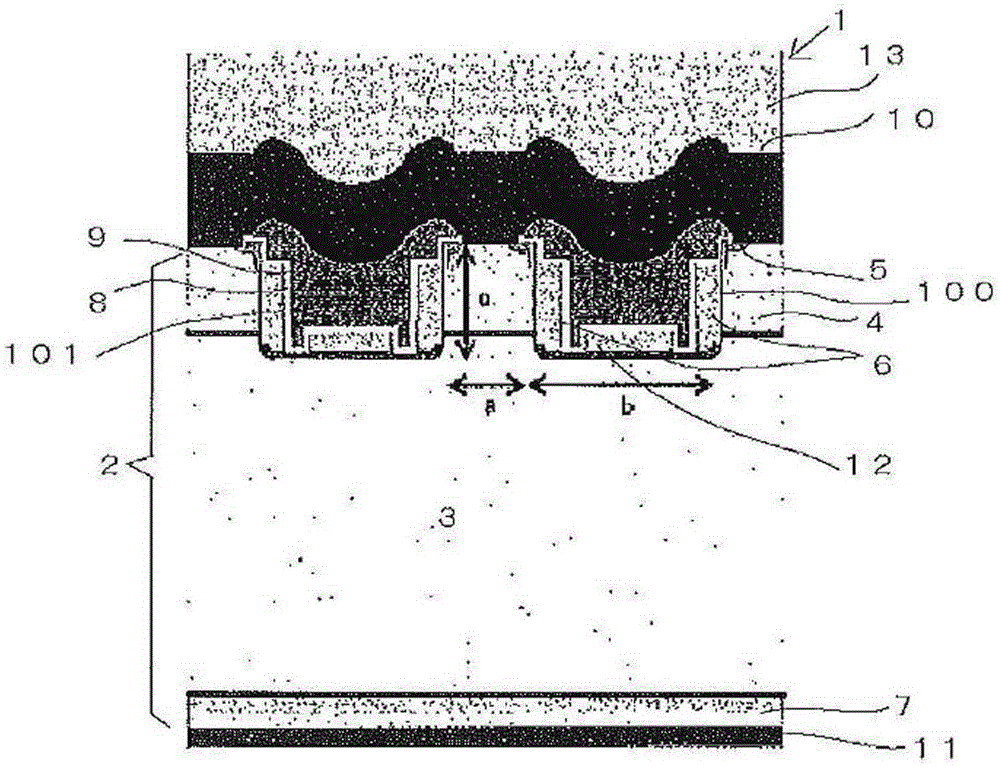

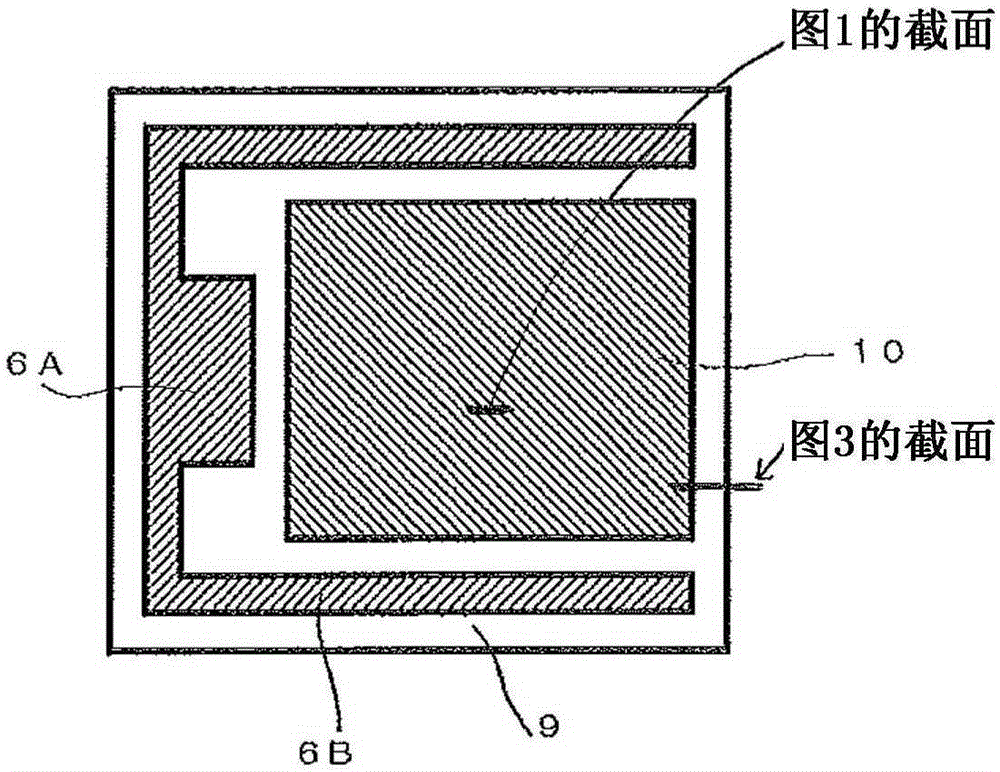

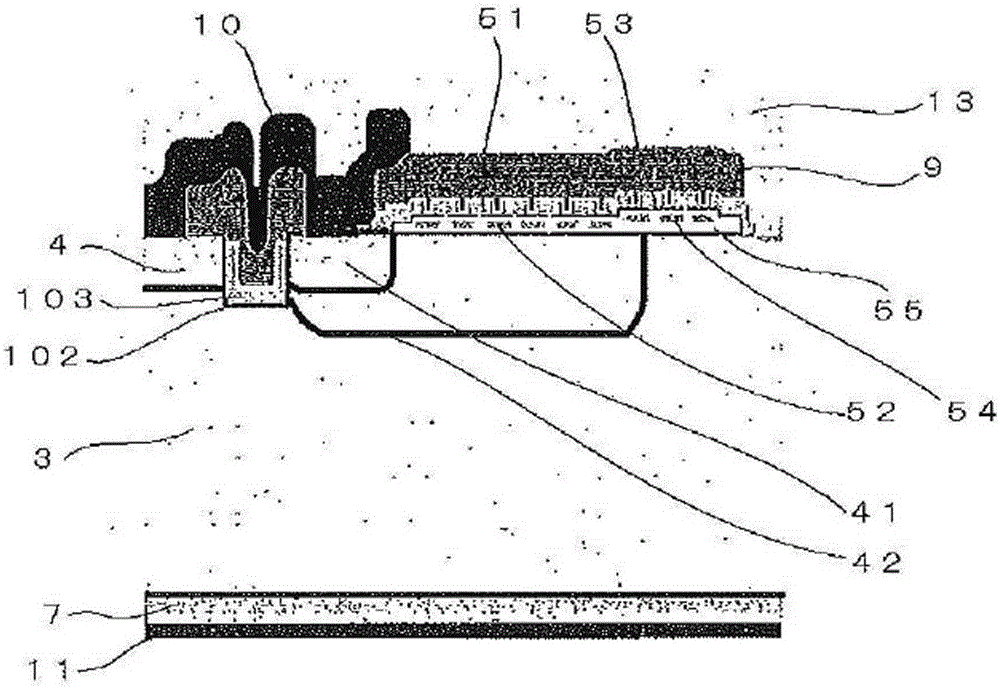

[0017] figure 1 A cross-sectional view of the semiconductor device 1 is shown. This semiconductor device 1 includes a trench gate type element portion (active region) formed on a semiconductor base 2 made of silicon. In this semiconductor substrate 2, an n-layer (first semiconductor region) 3 serving as a drift region and a p- layer (second semiconductor region) 4 serving as a base region are sequentially formed on a p-layer 7 serving as a collector region. A groove (gate trench) 100 penetrating through p − layer 4 and reaching n − layer 3 at the bottom is formed on the surface side of semiconductor substrate 2 . Slot 100 in with figure 1 Extended in the vertical direction of the paper, although not in the figure 2 It is shown in the plan view of , but a plurality of parallel grooves 100 are formed in the longitudinal direction of the paper. Here, the width b of the trenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com