A pole-holding lattice spanning frame on both sides of the expressway

A technology for expressways and spanning racks, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of guide rope and cable winding, damage from overpassing racks, stagnation of transmission wires, etc., to facilitate transportation, ensure stability, and facilitate erection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

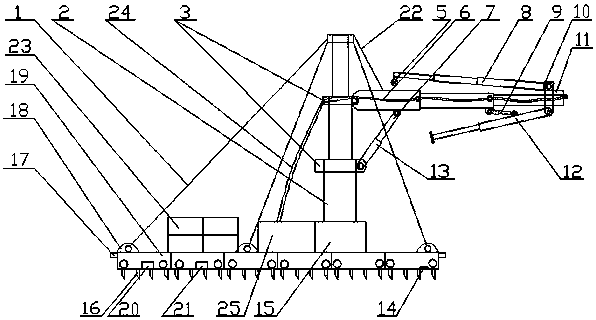

[0035] A pole-holding cross frame on both sides of an expressway, comprising a ground anchor mechanism for enhancing stability, a support mechanism arranged on the ground anchor mechanism, and a span mechanism arranged on the support mechanism, the ground anchor The mechanism, the supporting mechanism and the spanning mechanism are all connected to the control mechanism;

[0036] The ground anchor mechanism includes a ground anchor plate 19 composed of a plurality of ground anchor units, a counterweight unit 23 arranged on the ground anchor plate 19, a load-bearing ring 18 arranged on the peripheral side of the ground anchor plate 19, and a load-bearing ring connected to the ground anchor plate 19. 18 connected pulling ropes 1;

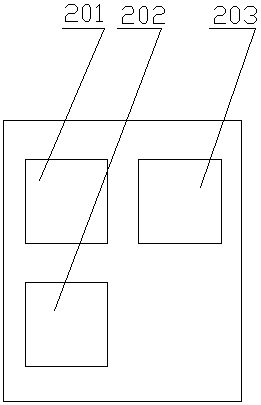

[0037] The support mechanism includes a fixed base 15, a telescopic rod 2 arranged on the fixed base 15, and a fixed base 3 arranged on the telescopic rod 2, and the telescopic rod 2 is arranged on the telescopic rod 2 to connect with the pull rope 1 ...

Embodiment 2

[0054] The difference from Embodiment 1 is that: the main telescopic arm 6 is provided with a support groove 11 that matches the first telescopic arm 8 .

[0055] The first fixed pulley 26 matched with the fixed pulley is arranged at the top of the telescopic rod.

[0056] In this embodiment, a support groove is added to support the first support arm, so as to ensure that the first telescopic arm can be strongly supported when it is deployed, ensuring the stability of the structure, and the fixed pulley and the first fixed pulley are set Conveyor rope for item conveyance.

Embodiment 3

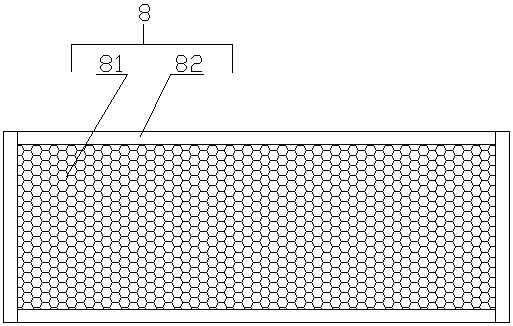

[0058] The difference from the second embodiment is that the first telescopic arm 8 has a honeycomb structure 82 inside and a chrome-plated layer 81 on its surface.

[0059] The honeycomb structure is arranged inside the first telescopic arm adopted in this embodiment, which can reduce the structural weight without changing the structural strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com