Novel method for reducing cogging torque of permanent magnet synchronous motor

A permanent magnet synchronous motor, cogging torque technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electrical components, etc., can solve the problem of no calculation method and achieve the effect of reducing the simulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

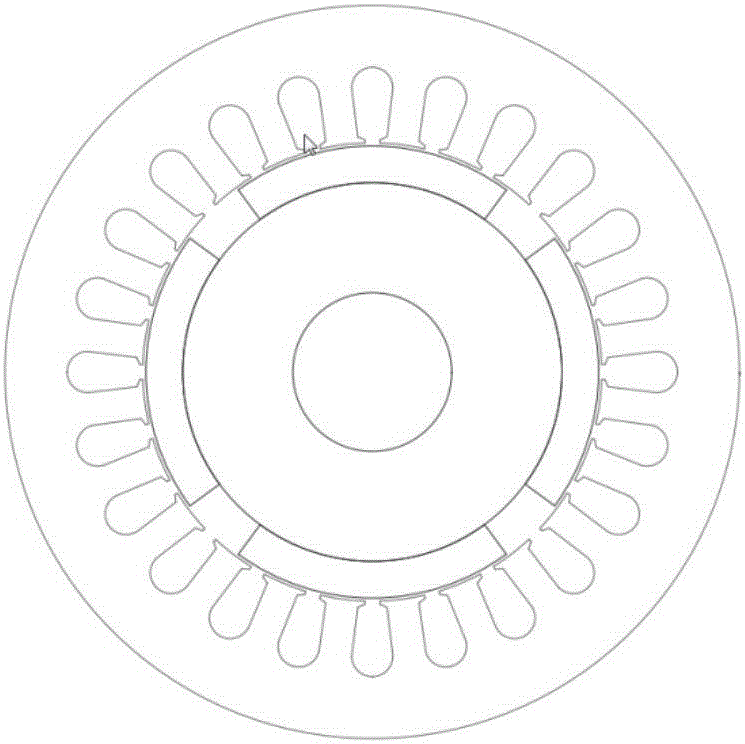

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

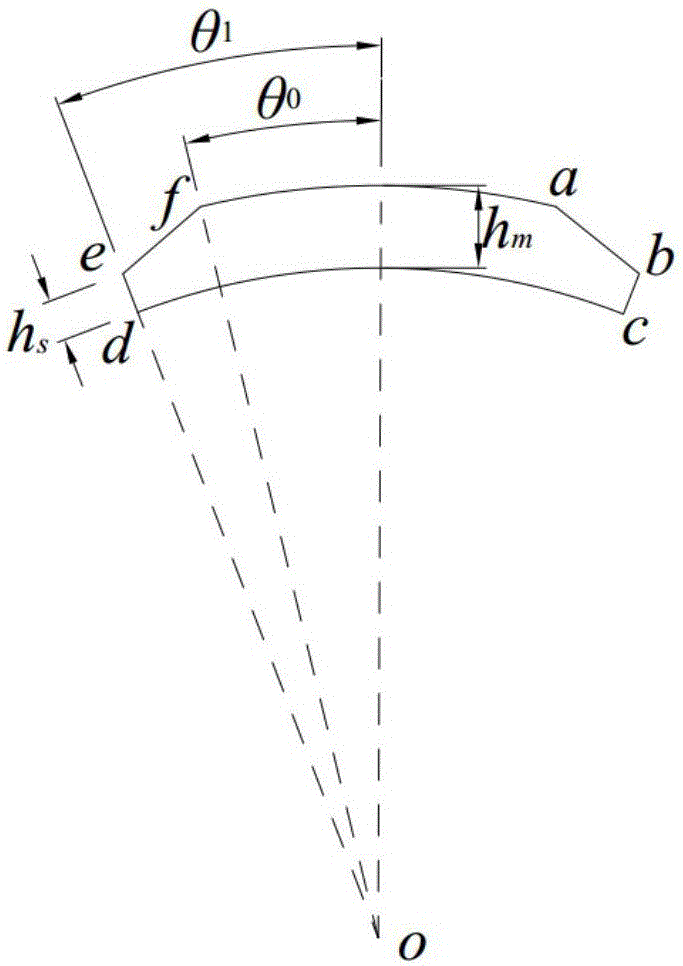

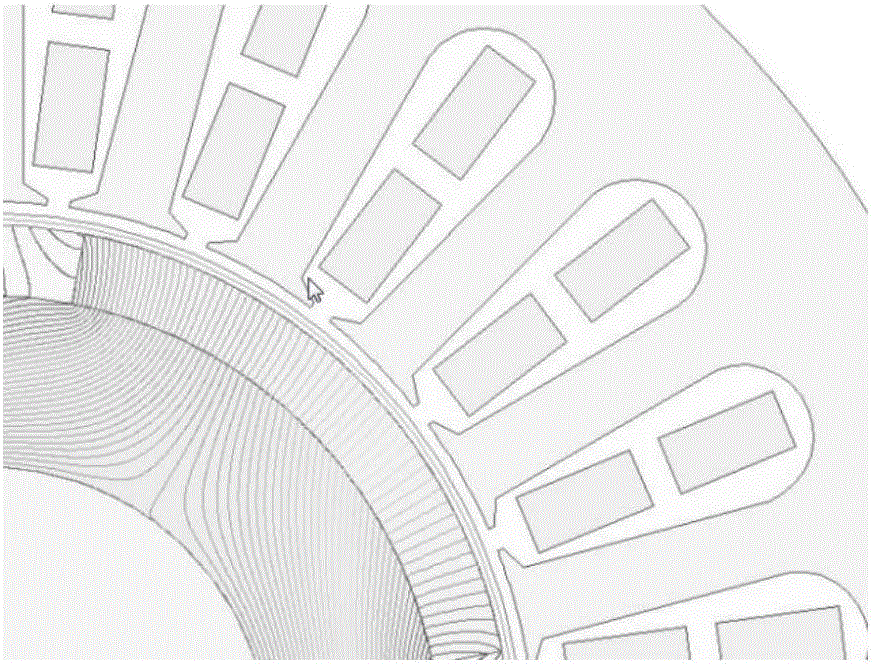

[0033] Permanent magnet structure of the present invention such as figure 2 as shown, image 3 It is a schematic diagram of magnetization of the permanent magnet of the present invention.

[0034] Such as figure 2 , The chamfering of the permanent magnet adopts a symmetrical way to the central axis. o is the center of arc af and arc cd, the lengths of ed and bc are equal, defined as h s , the permanent magnet thickness is defined as h m . h for h s and permanent magnet thickness h m The ratio of h s / h m , defined as the chamfer length proportional coefficient. θ 1 is the angle corresponding to the polar arc coefficient of the permanent magnet, that is, α p π / 2p, 0 is the angle of chamfering. If the angle of the chamfered corner is θ 0 Determined, then the determination method of h is as follows:

[0035]

[0036] in:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com