Palm wax-silicon resin compound high-resilience polyurethane foaming product release agent

A technology for foaming products and release agents, which is applied in the field of release agents for high-resilience polyurethane foam products compounded with palm wax and silicone resin. Problems such as complex edges and corners of the product, to achieve the effect of improving the unevenness of the cells, high demoulding times, and low mold pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Heat and melt 3.0wt.% palm wax and 1.0wt.% silicone resin at 95°C. After the melt is completely melted, continue stirring for 3 minutes, then lower the temperature to 85°C, and add 0.4wt.% Tween80 With 0.4wt.% of SPAN80, the emulsion was ultrasonically oscillated for 90 seconds and emulsified with a high-shear homogeneous emulsifier for 1 hour (stirring speed was 20000r / min), and finally 55.2wt.% solvent was gradually added dropwise to form a thick The emulsion is the stock solution of release agent for high-resilience polyurethane foam products compounded with palm wax and silicone resin. It can be sprayed directly after adding 40.0wt.% n-heptane at room temperature.

[0018] Emulsion stability: After being centrifuged at 3000r / min for 5 minutes, the release agent emulsion prepared by this formula will not be demulsified or delaminated.

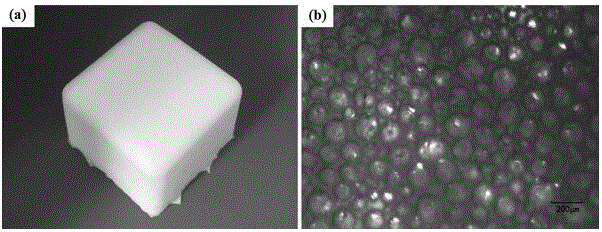

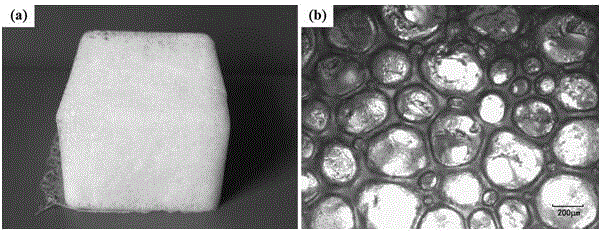

[0019] Release effect: Heat the polyurethane foam mold to 60°C, spray the release agent evenly on the surface, and dry th...

Embodiment 2

[0021] Example 2: Heat and melt 3.0wt.% palm wax and 1.0wt.% silicone resin at 95°C. wt.% fatty alcohol polyoxyethylene ether and 0.5wt.% zinc stearate, then ultrasonically oscillate the emulsion for 90 seconds and emulsify it with a high-shear homogeneous emulsifier for 1 hour (stirring speed is 20000r / min), Finally, add 55.0wt.% solvent gradually to form a thick emulsion, which is the stock solution of release agent for high resilience polyurethane foam products compounded with palm wax and silicone resin. When using it, add 40.0wt.% n-heptane at room temperature It can be used directly by spraying.

[0022] Emulsion stability: After being centrifuged at 3000r / min for 5 minutes, the release agent emulsion prepared by this formula will not be demulsified or delaminated.

[0023] Release effect: heat up the polyurethane foam mold to 70°C, spray the release agent evenly on the surface, and dry the solvent with a spray gun, then mix the high-resilience polyurethane A and B mate...

Embodiment 3

[0024] Example 3: Heat and melt 2.0wt.% palm wax and 2.0wt.% silicone resin at 95°C. After the melt is completely melted, continue stirring for 3 minutes, then lower the temperature to 85°C, and add 0.2wt.% Tween80 With 0.2wt.% of SPAN80, the emulsion was ultrasonically oscillated for 100 seconds and emulsified with a high-shear homogeneous emulsifier for 0.5 hours (stirring speed was 30000r / min), and finally 55.6wt.% solvent was gradually added dropwise to form a thick The emulsion is the stock solution of release agent for high-resilience polyurethane foam products compounded with palm wax and silicone resin. It can be sprayed directly after adding 40.0wt.% n-heptane at room temperature.

[0025] Emulsion stability: After being centrifuged at 3000r / min for 5 minutes, the release agent emulsion prepared by this formula will not be demulsified or delaminated.

[0026] Release effect: heat up the polyurethane foam mold to 70°C, spray the release agent evenly on the surface, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com