Time difference method ultrasonic flowmeter

An ultrasonic and flowmeter technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve the problems of flowmeter performance degradation, flow fluctuation error, IC integration, etc., to improve energy utilization rate , increase the installation distance, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

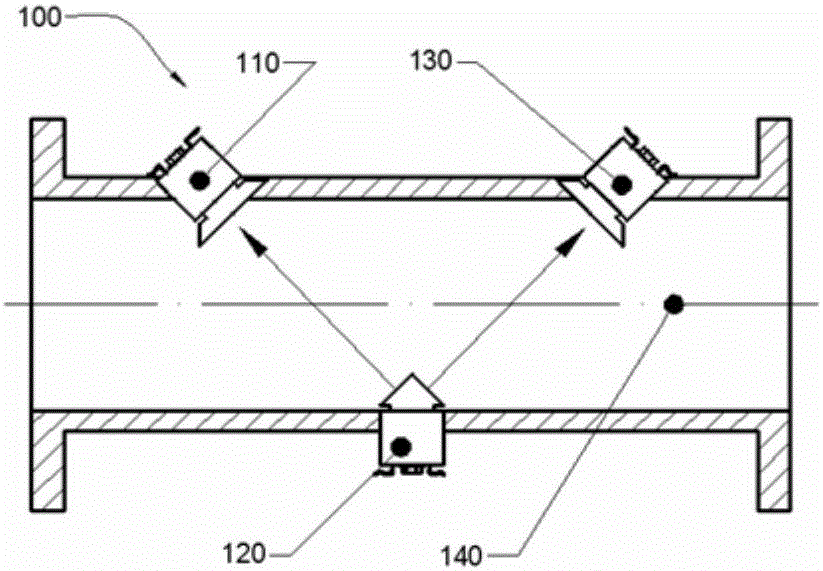

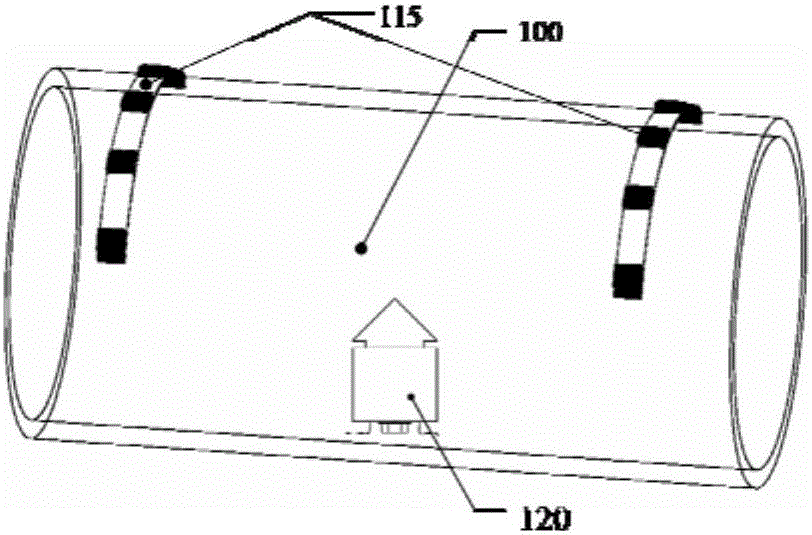

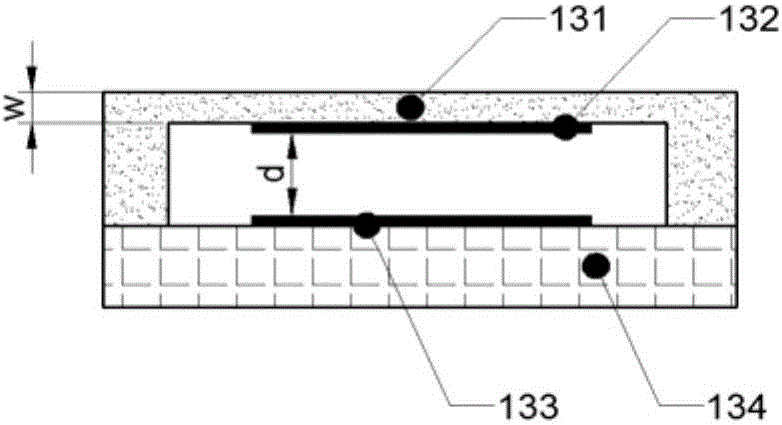

[0022] see Figure 1~6 The transit-time ultrasonic flowmeter 100 according to the embodiment of the present invention includes an ultrasonic transducer 120 with a tapered matching layer, a reverse flow ultrasonic receiver 110 , a downstream ultrasonic receiver 130 , and a pipe 140 . The ultrasonic transducer 120 with a tapered matching layer is only used as an ultrasonic transmitter and continuously emits ultrasonic waves during operation, while the ultrasonic receiver 110 and downstream ultrasonic receiver 130 are only used as ultrasonic receivers, so the ultrasonic flowmeter 100 transmits and receives ultrasonic waves. Ultrasonic can be carried out simultaneously, compared with the traditional time-sharing ultrasonic flowmeter, it reduces the error caused by different measurement time when the flow fluctuates, and increases the data collection rate.

[0023] Since the piezoelectric ultrasonic transducer has a higher output sound pressure than the capacitive ultrasonic transd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com