Debugging method and debugging system for distribution automation equipment

A power distribution automation and debugging system technology, which is applied in the direction of circuit breaker testing, measuring electricity, measuring electrical variables, etc., can solve the problems of affecting the debugging effect, heavy workload, and difficulty in providing AC working power, so as to reduce the debugging workload , the effect of verifying the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions in the present invention will be clearly and completely described below in conjunction with specific embodiments.

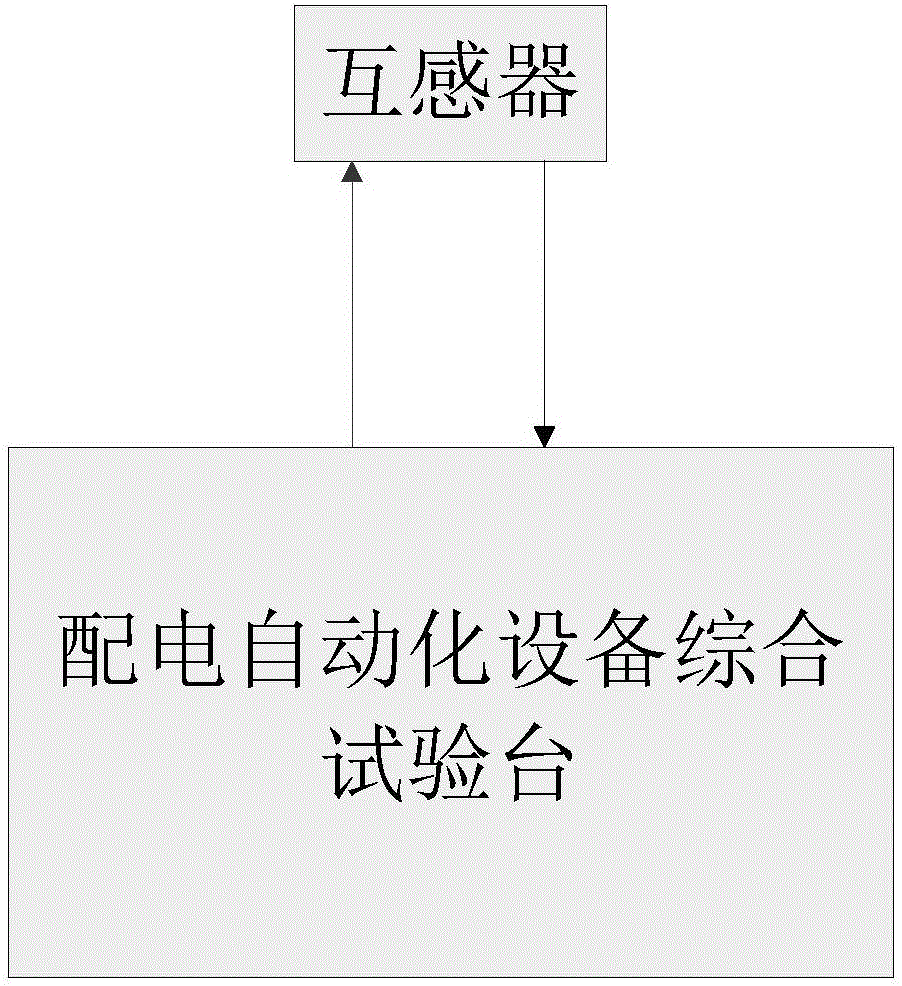

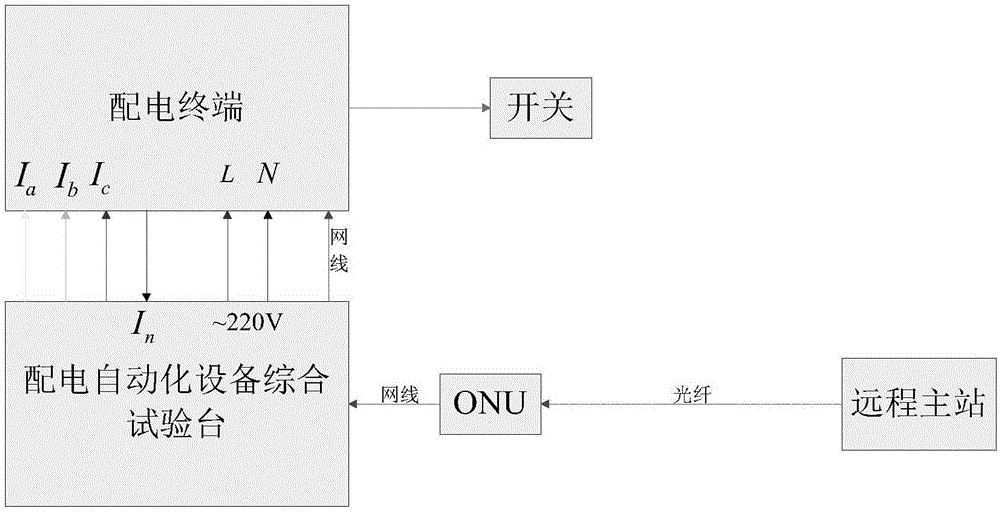

[0056] The invention provides a debugging method for power distribution automation equipment. The power distribution automation equipment debugging method includes a single test method for power distribution automation terminals and switchgear, a transformer ratio test method, and a master station for power distribution automation equipment. System joint debugging method.

[0057] A method for debugging power distribution automation equipment, comprising the steps of:

[0058] Step 1. Single test of distribution automation terminal and switchgear:

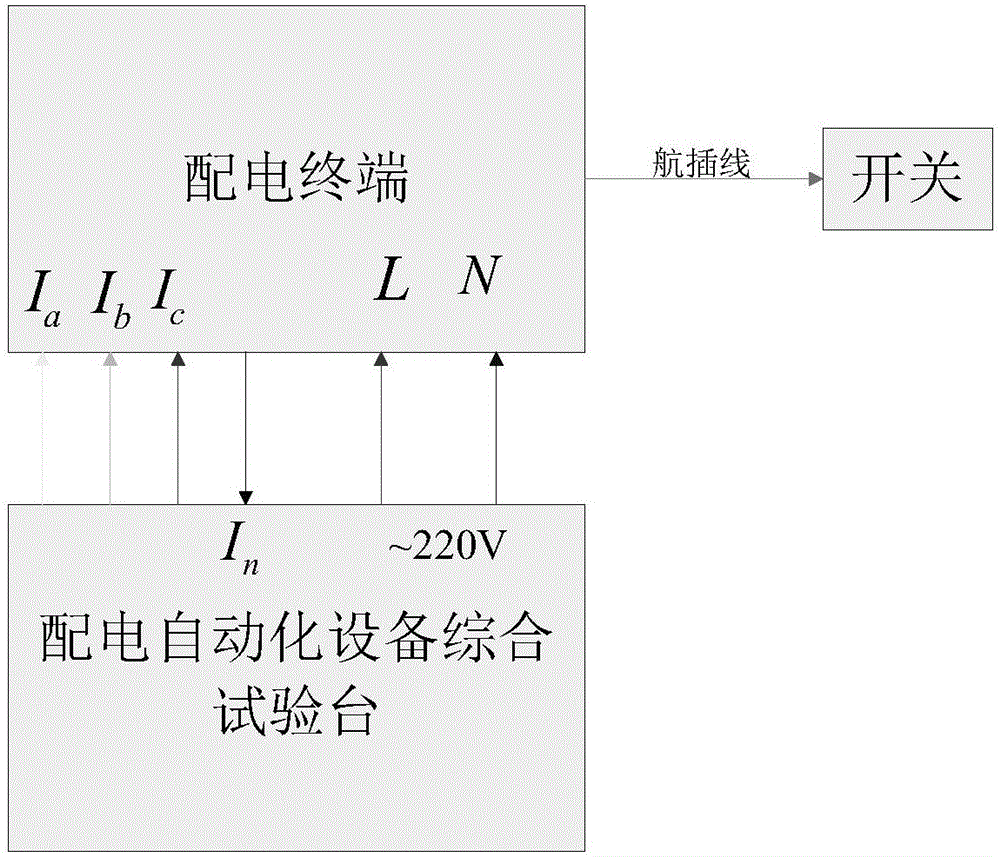

[0059] The schematic diagram of the single test system of distribution automation terminal and switchgear in one embodiment of the present invention is as follows figure 1 As shown, the described distribution automation terminal and switchgear unit test system is a subsystem of a distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com