Manufacturing method of nanocrystalline common-mode inductor

A common mode inductance and manufacturing method technology, applied in the field of inductance, can solve the problems of large volume, difficult to balance inductance, small volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described in conjunction with the following examples.

[0038] A method for manufacturing a nanocrystalline common-mode inductor in this embodiment includes the following steps:

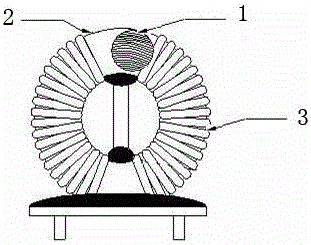

[0039] Step 1: Install a core mold with a diameter of 22mm on the amorphous automatic winding machine, and wind the 13mm long iron-based nanocrystalline strip into a nanocrystalline magnetic ring with an outer diameter of 38mm, an inner diameter of 22mm, and a height of 13mm 1.

[0040] Then, detect the tightness of the amorphous magnetic ring: the external force pushes the nanocrystalline magnetic ring 1 from the direction perpendicular to the bandwidth of the nanocrystalline magnetic ring 1

[0041] Compression deformation, after the external force is removed, the height dimension of the magnetic ring in the direction of the force can be restored to 80% greater than that before the external force is not applied. This step can eliminate the internal stress of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com