Busbar-free double-sided battery module and its manufacturing process

A double-sided battery and manufacturing process technology, applied in the field of solar cells, can solve the problems of prone to cracks, large battery power loss, and large short-circuit current, so as to reduce the problems of hidden cracks and lobes, improve conversion efficiency, and increase short-circuit current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

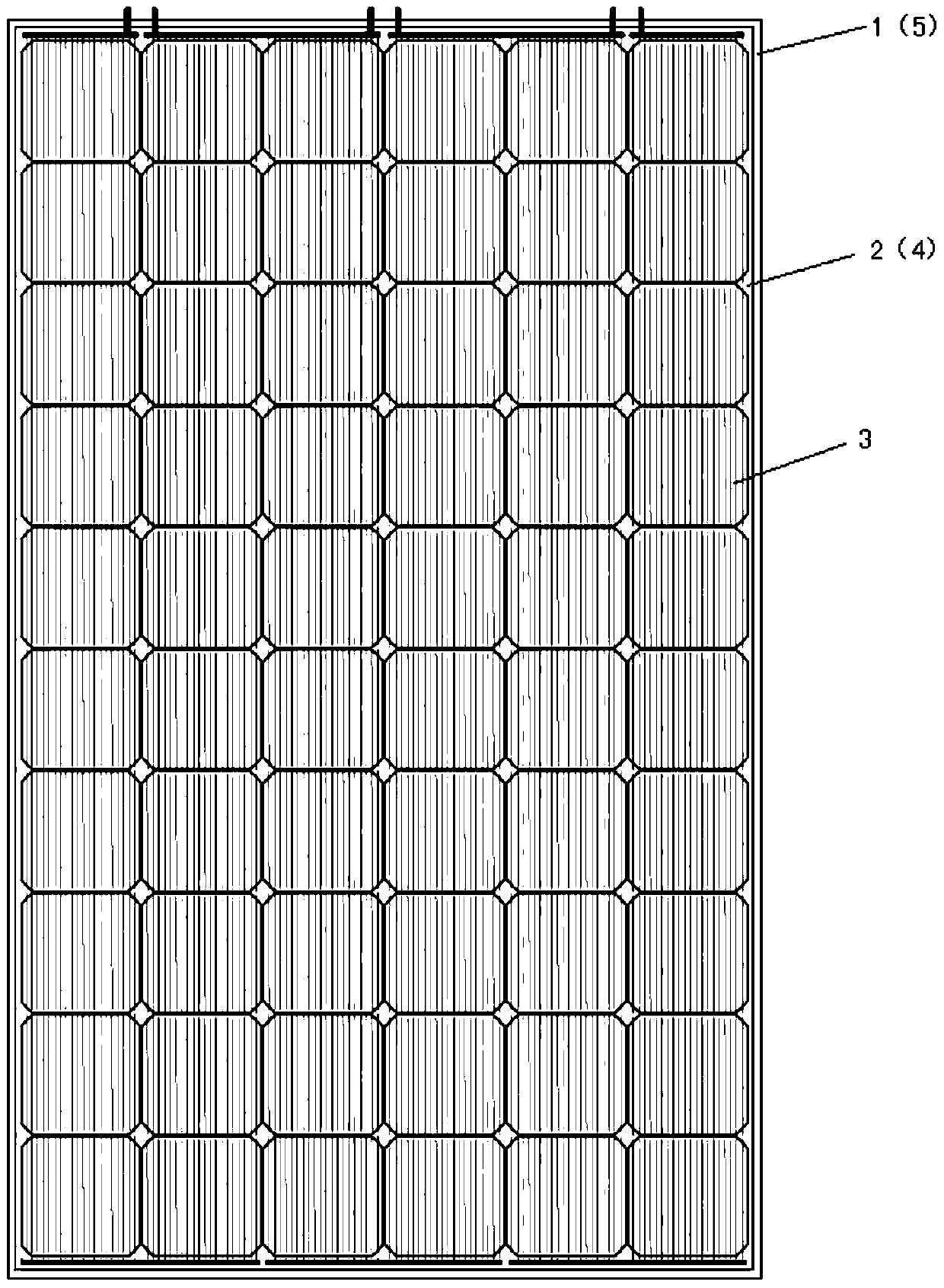

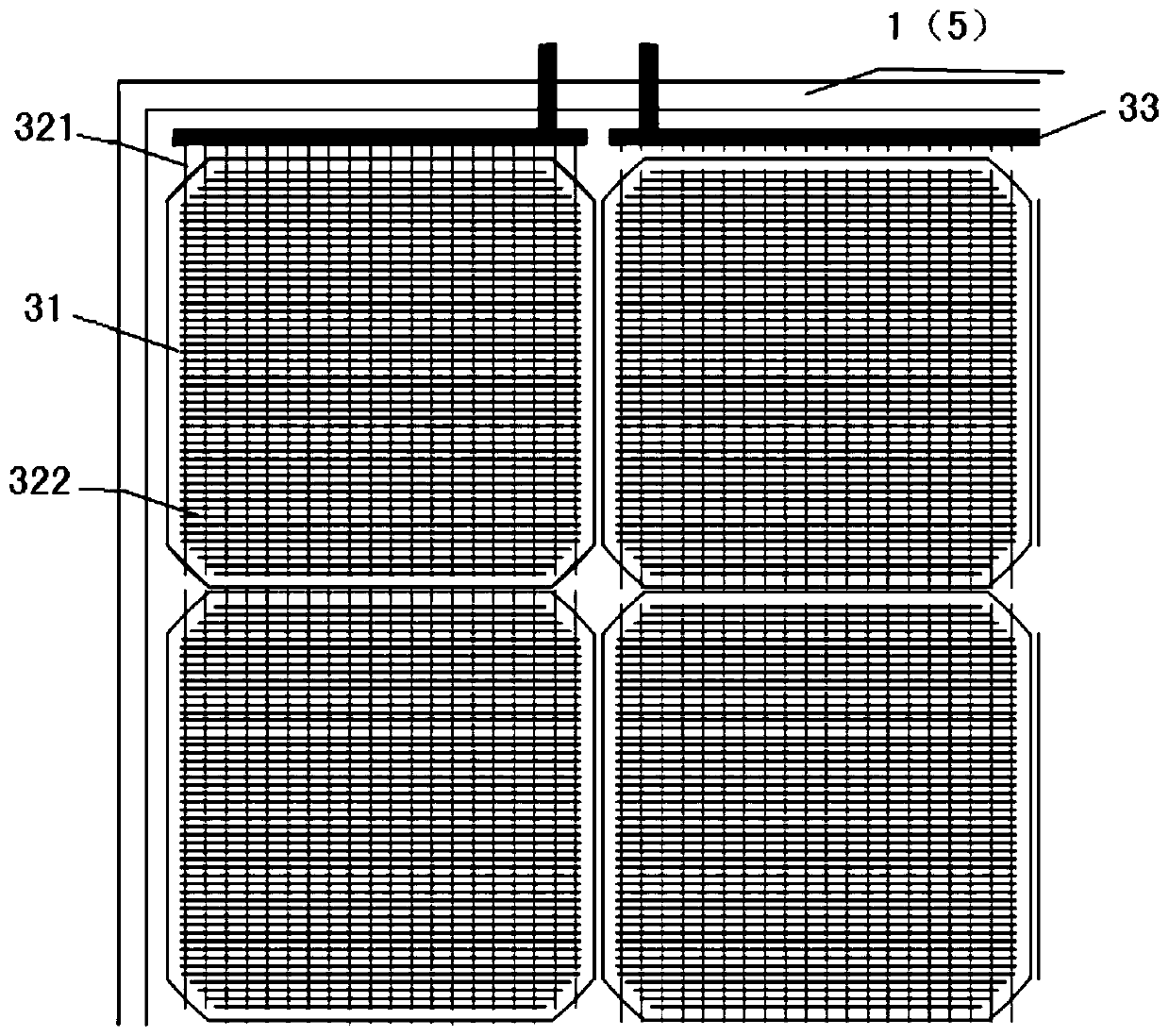

[0024] see figure 1 , with reference to figure 2 , image 3 , Figure 4 , Figure 5 , the busbar-free double-sided battery assembly of the present invention includes a front tempered coated glass 1, a front EVA film 2, a busbar-free double-sided cell array 3, a back EVA film 4 and a back toughened coated glass 5, which are sequentially stacked.

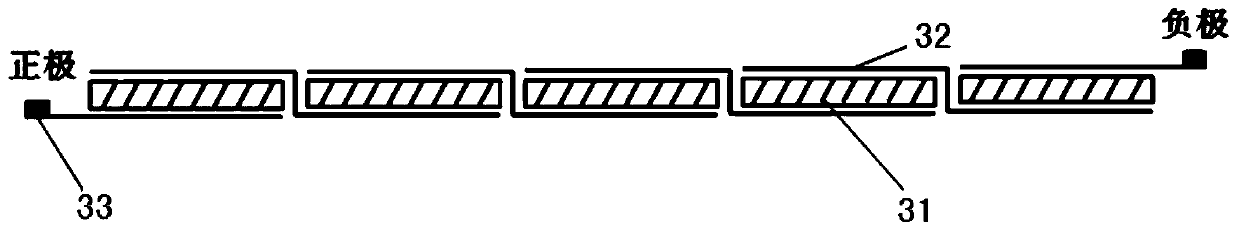

[0025] The busbar-free double-sided cell array 3 in the present invention includes a plurality of busbar-free double-sided cells 31 and a plurality of copper-tin metal wire films 32, and both sides of the busbar-free double-sided cells 31 have no busbar lines. There are only fine grid lines 311, and the numbers of the front and rear fine grid lines are 80 and 75 respectively. Each piece of copper-tin wire film connects two battery pieces, that is, the first piece of copper-tin metal wire film connects the front of the first battery piece and the back side of the second battery piece, and the second piece of copper-tin metal wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com