Flat type industrial control method and system

A flat, industrial control technology, applied in transmission systems, electrical components, etc., to achieve the effects of cost reduction, high performance, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

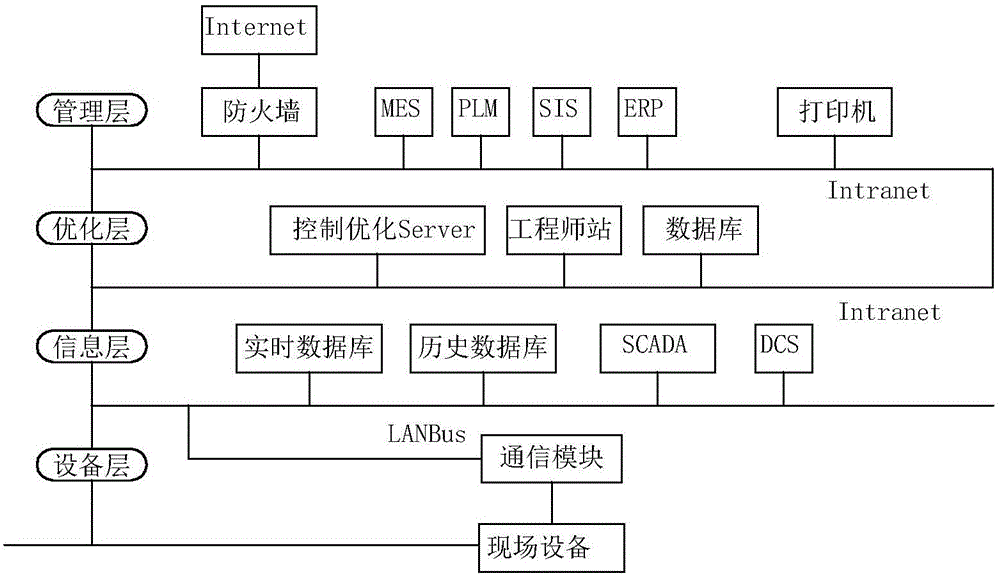

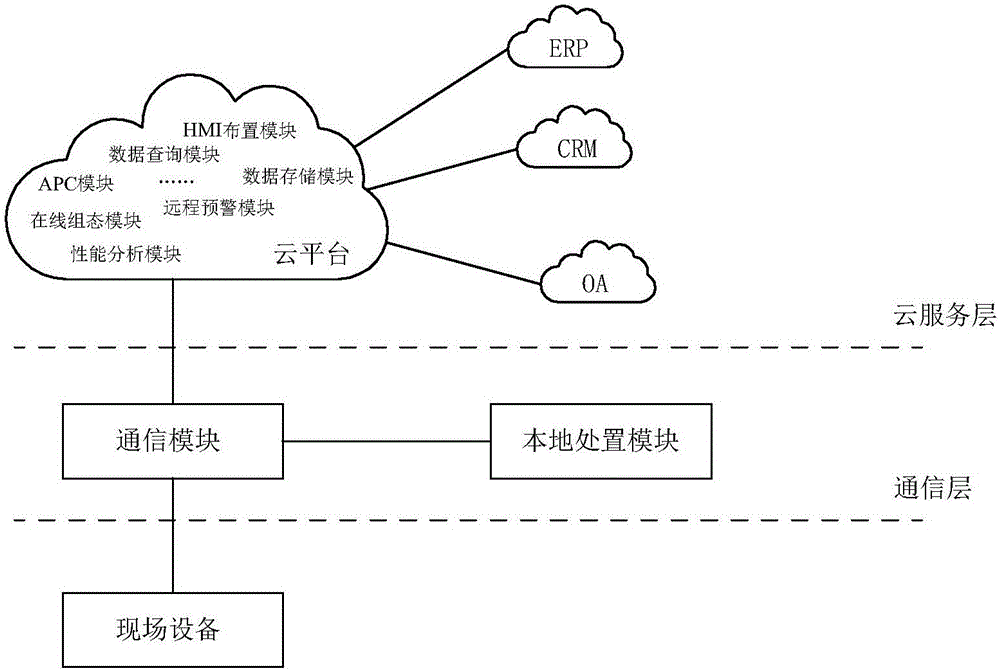

[0026] The present invention provides a flat industrial control method and a flat industrial control system, such as figure 2 As shown, it is mainly composed of two layers: the communication layer and the cloud service layer. The data collected by field equipment does not need to be sent to SCADA through data acquisition logic control modules such as PLC and DDC. At the same time, no SCADA and other monitoring software and supporting hardware equipment are arranged on site , No need to build on-site central control room and other cost-intensive control system facilities. Instead, the data collected by field devices is directly uploaded to the cloud service layer by the communication layer without any processing, and according to user needs, it cooperates with the modular components of various functions of the cloud service layer to perform da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com