Egg yolk protein powder product capable of being suspended stably in water and preparation method thereof

A protein powder, egg yolk powder technology, applied in the direction of protein food ingredients, egg protein ingredients, food science, etc., to achieve the effects of increasing stability, enhancing emulsifying performance, and improving appearance and properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

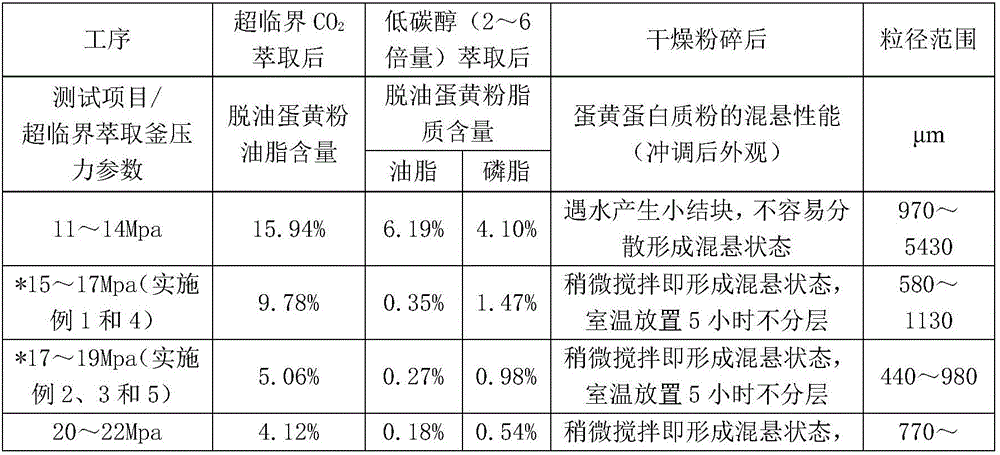

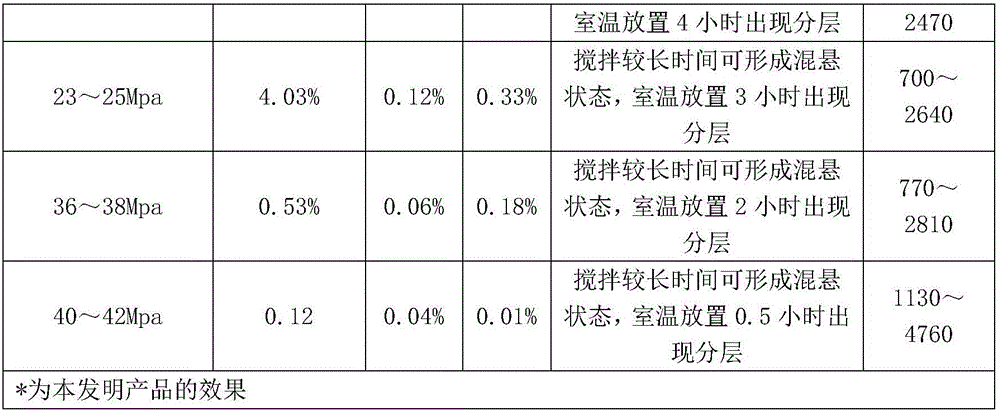

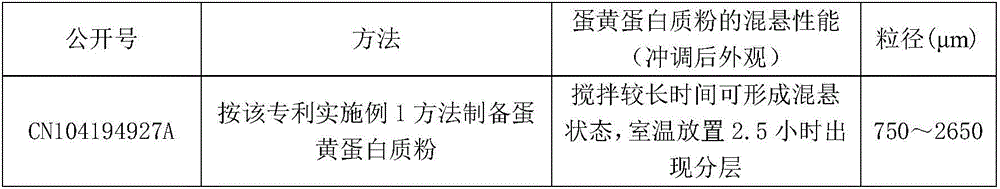

Examples

Embodiment 1

[0025] Get egg yolk powder 6kg, place in supercritical CO 2 In the extraction kettle, open the equipment to preheat the system to 32-36°C, open the inlet valve of the extractor, and introduce CO 2 , after the system pressure reaches equilibrium, open the CO 2 High-pressure metering pump, adjust the throttle valve to keep the pressure of the extraction kettle between 15 and 17Mpa, and control the CO 2 The flow rate is about 90Kg / h, and the throttle valve is adjusted to keep the pressure of the separation tank 1 at 10-12Mpa, and the pressure of the separation tank 2 at 8-10Mpa, and the egg oil is released at the bottom of the separator every 0.5 hours for 5 hours. Release the above-mentioned deoiled egg yolk powder, add 24 liters of ethanol, stir for 2 hours, filter under reduced pressure, and drain it, and dry the filter residue under reduced pressure at 40°C for 2 hours, and then grind at low temperature after drying to obtain egg yolk protein with a phospholipid content of 1...

Embodiment 2

[0027] Get egg yolk powder 20kg, place in supercritical CO 2 In the extraction kettle, open the equipment to preheat the system to 32-36°C, open the inlet valve of the extractor, and introduce CO 2 , after the system pressure reaches equilibrium, open the CO 2 High-pressure metering pump, adjust the throttle valve to keep the pressure of the extraction kettle between 17 and 19Mpa, and control the CO 2 The flow rate is about 60Kg / h, and the throttle valve is adjusted to keep the pressure of separation kettle 1 at 10-12Mpa, and the pressure of separation kettle 2 at 8-10Mpa. Egg oil is released at the bottom of the separator every 0.5 hours for 3 hours. Release the above-mentioned deoiled egg yolk powder, add 40 liters of ethanol, stir for 5 hours, filter under reduced pressure, and drain it, and dry the filter residue under reduced pressure at 40°C for 2 hours, and then pulverize at a low temperature after drying to obtain egg yolk protein with a phospholipid content of 1.23%....

Embodiment 3

[0029] Get egg yolk powder 20kg, place in supercritical CO 2 In the extraction kettle, open the equipment to preheat the system to 32-36°C, open the inlet valve of the extractor, and introduce CO 2 , after the system pressure reaches equilibrium, open the CO 2 High-pressure metering pump, adjust the throttle valve to keep the pressure of the extraction kettle between 17 and 19Mpa, and control the CO 2 The flow rate is about 90Kg / h, and the throttle valve is adjusted to keep the pressure of the separation tank 1 at 10-12Mpa, and the pressure of the separation tank 2 at 8-10Mpa, and the egg oil is released at the bottom of the separator every 0.5 hours for 5 hours. Release the above-mentioned deoiled egg yolk powder, add 120 liters of ethanol, stir for 1 hour, filter under reduced pressure, and drain it, and dry the filter residue under reduced pressure at 40°C for 2 hours, and then grind at low temperature after drying to obtain egg yolk protein with a phospholipid content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com