Degradable bioactive composite ceramic microsphere stent material, and preparation method and application thereof

A technology of bioactive ceramics and composite ceramics, used in tissue regeneration, medical science, prosthesis, etc., can solve problems such as porous ceramic stents that have not yet been found, and improve the ability to promote osteogenesis and vascularization, and is conducive to osteogenesis and vascularization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

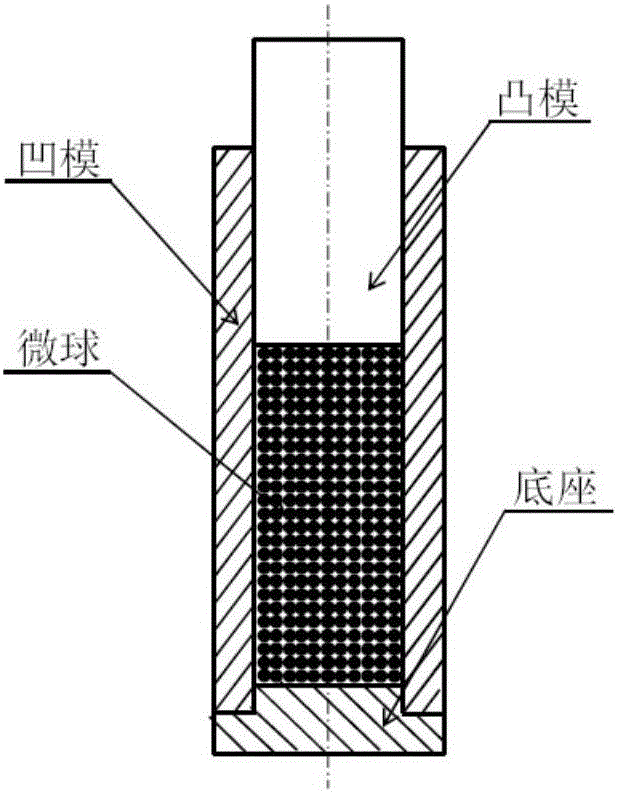

[0033] The preparation method of the β-tricalcium phosphate composite ceramic microsphere support is as follows:

[0034] (1) Using (NH4)2HPO4, CaCO3, MgCO3, Na2CO3 as raw materials, the molar percentage of oxides CaO:P2O5:MgO:Na2O corresponding to each substance is 40:40:10:10, mix the raw materials evenly, put In the furnace, heat to 1000°C and keep it warm for 1 hour to obtain a clear glass solution, then pour the glass solution into water to quench, collect glass particles, dry at 150°C, grind, and pass through a 1000-mesh sieve to obtain a low melting point Bio-glass powder;

[0035] (2) The steps of preparing β-tricalcium phosphate composite microspheres by droplet condensation method are as follows: dissolving gelatin at a ratio of 8 g / 100 mL in deionized water at 30 °C to make gelatin with a concentration of 8% (w / v) solution. The β-tricalcium phosphate powder and the bioglass powder prepared in step (1) are uniformly mixed, and the mass ratio of β-tricalcium phosphate...

Embodiment 2

[0039] The preparation method of calcium silicate composite ceramic microsphere support is:

[0040] (1) Using B2O3, P2O3, CaCO3, SiO2, and Na2CO3 as raw materials, the molar percentage of the oxides B2O3:P2O5:CaO:SiO2:Na2O corresponding to each substance is 4:6:30:45:15, and mix the raw materials evenly , put it into a furnace, heat it to 1200°C, keep it warm for 3 hours to obtain a clear glass solution, then pour the glass solution into water to quench, collect glass particles, dry at 150°C, grind, pass through a 1000-mesh sieve, that is Obtain low melting point bioglass powder;

[0041] (2) The steps of preparing calcium silicate composite microspheres by droplet condensation method are as follows: dissolve xanthan gum in 30°C deionized water at a ratio of 4g / 100mL to make xanthan gum with a concentration of 4% (w / v). Raw gum solution. Sodium hydroxypropyl cellulose was dissolved in 60°C deionized water at a ratio of 3g / 100mL to make a sodium hydroxypropyl cellulose solut...

Embodiment 3

[0045] The preparation method of the hydroxyapatite / β-tricalcium phosphate / calcium silicate composite microsphere scaffold is as follows:

[0046] (1): Using (NH4)2HPO4, CaCO3, SrCO3, and Na2CO3 as raw materials, the molar percentage of oxides P2O5:CaO:SrO:Na2O corresponding to each substance is 45:40:5:10, mix the raw materials evenly, and put Put it into a furnace, heat it to 1200°C, keep it warm for 3 hours to obtain a clear glass solution, then pour the glass solution into water to quench, collect glass particles, dry at 150°C, grind, and pass through a 1000-mesh sieve to obtain a low-density glass solution. Melting point bioglass powder;

[0047] (2) The steps of preparing calcium silicate composite microspheres by droplet condensation method are as follows: dissolve pectin in deionized water at 30°C at a ratio of 0.3g / 100mL to make pectin with a concentration of 0.3% (w / v). glue solution. Dissolve cyclodextrin at a ratio of 10g / 100mL in deionized water at 60°C to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com