Automatic ring-cone-process uniform-mixing and division apparatus for dry bulk material

A mixing and material technology, applied in the field of mining machinery, can solve the problems of difficult to eliminate errors, easy generation of dust, large workload, etc., to reduce the workload and the harm of dust to the body, reduce the impact, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

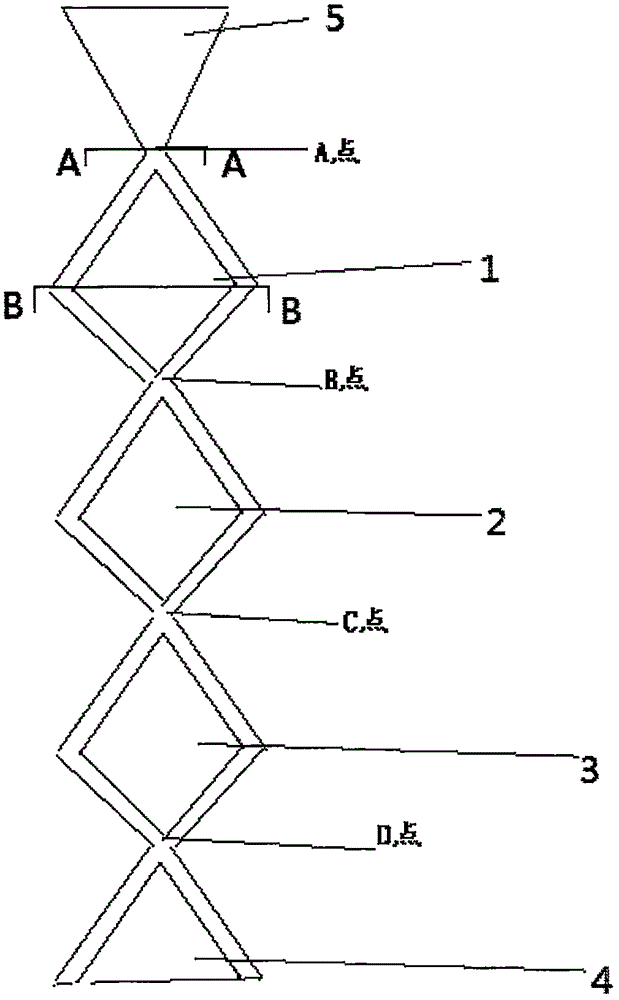

[0014] like Figure 1-Figure 3 As shown, the embodiment of the present invention provides an automatic ring-cone mixing and shrinking equipment for dry bulk materials, including a feeding port, a four-time ring-cone mixing system, and an annular outlet; the four-time ring-cone The mixing system is composed of the first ring cone 1, the second ring cone 2, the third ring cone 3 and the fourth ring cone 4 connected in sequence from top to bottom; the first ring cone 1, the second ring cone The ring cone 2 and the third ring cone 3 are composed of an upright cone and an inverted cone, and the fourth ring cone 4 is only composed of an upright cone;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com