A production method of high-strength pipeline steel with low yield ratio

A high-strength pipeline steel and production method technology, applied in the field of metal rolling, can solve the problems of high strength and low yield ratio, and achieve good toughness, excellent yield ratio range, and huge social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

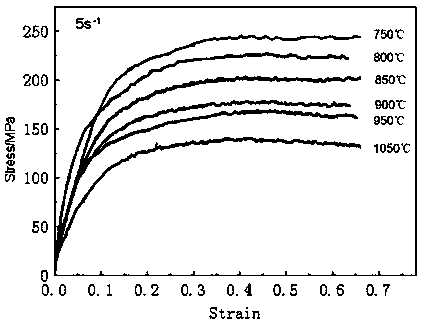

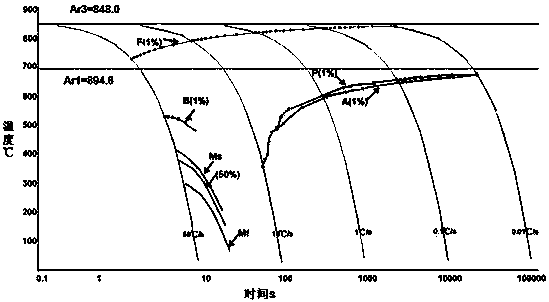

[0032] Example 1: Purified molten steel is obtained through smelting, and then cast into slabs through continuous casting machines. The composition weight percentages are: C: 0.03%, Si: 0.025%, Mn: 1.50%, P: 0.0018%, S : 0.006%, Als: 0.015%, Nb: 0.055%, Ti: 0.030%, Cr: 0.20%; Pcm: 0.13%; heat the billet to 1100°C and keep it for 320min; The pressure is 22Mpa, and the furnace oxide scale on the surface is completely removed; then rolling in the austenite recrystallization zone in the first rolling process, the starting rolling temperature is 1020°C, after the slab widening rolling is completed, four passes are used for elongation rolling In the first rolling, the pass reduction rates are 16%, 18%, 18%, and 25%, respectively, and the cumulative effective reduction rate is 77%. The temperature range of the second rolling start rolling temperature is 780°C. The pass reduction rates are 13%, 15%, 17%, and 10% respectively; the cooling temperature is 670°C, the DQ cooling section co...

Embodiment 2

[0034] Example 2: Purified molten steel is obtained through smelting, and then continuously cast into a slab through a continuous casting machine. The composition weight percentages are: C: 0.05%, Si: 0.06%, Mn: 1.61%, P: 0.013%, S : 0.005%, Als: 0.025%, Nb: 0.059, Ti: 0.020%, Cr: 0.26%; Pcm: 0.15%; heat the billet to 1130°C and keep it for 340min; to 26Mpa, thoroughly remove the furnace oxide scale on the surface; then carry out rolling in the austenite recrystallization zone in the first rolling process, the starting rolling temperature is 1050°C, and after the slab widening rolling is completed, four passes are used for elongation rolling Rolling, the pass reduction rate is 16%, 17%, 19%, 20% respectively, the cumulative effective reduction rate is 72%, the starting temperature of the austenite non-recrystallized zone in the second rolling pass is 795 ° C, four passes are adopted rolling, the pass reduction rate is 12%, 14%, 16%, 10% respectively. The starting cooling temp...

Embodiment 3

[0036] Example 3: Purified molten steel is obtained by smelting, and then cast into slabs through continuous casting machines. The composition weight percentages are: C: 0.07%, Si: 0.08%, Mn: 1.70%, P: 0.025%, S : ≤0.007%, Als: 0.045%, Nb: 0.070%, Ti: 0.010%, Cr: 0.30%; Pcm: 0.18%; heat the slab to 1150°C and keep it for 360min; turn on all the high-pressure water for descaling and descaling The water pressure is 30Mpa, and the surface furnace scale is completely removed; then the rolling in the austenite recrystallization zone in the first rolling process is carried out, and the starting rolling temperature is 1080°C. Pass rolling, the pass reduction rate is 17%, 18%, 19%, 22%, the cumulative effective reduction rate is 76%, and the rolling temperature range of the austenite non-recrystallized zone in the second rolling pass is 810°C , using four-pass rolling, the pass reduction rate is 12%, 15%, 15%, 10%, respectively, the cooling temperature is 690 °C, and the DQ cooling se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com