Aerated concrete building block grooving machine

A technology of aerated concrete and slotting machine, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., and can solve the problem that the groove position, groove width, straightness, and groove depth cannot be effectively controlled and other problems, to achieve the effect of high construction efficiency, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited.

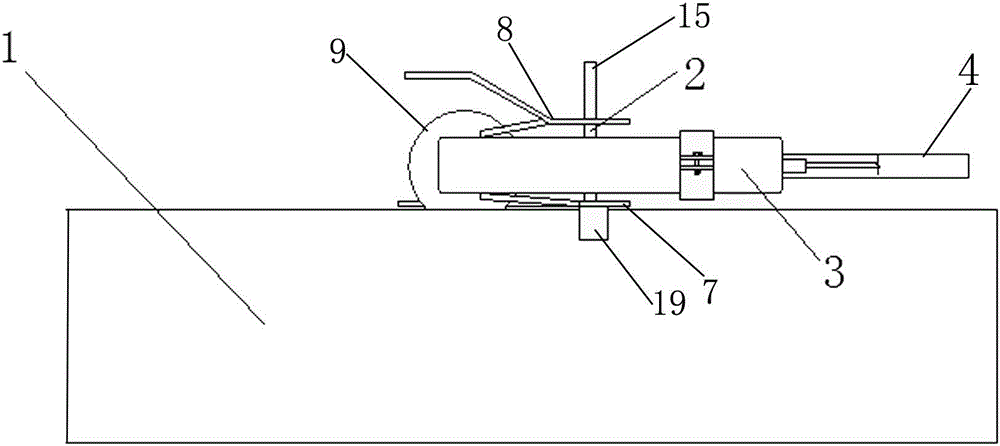

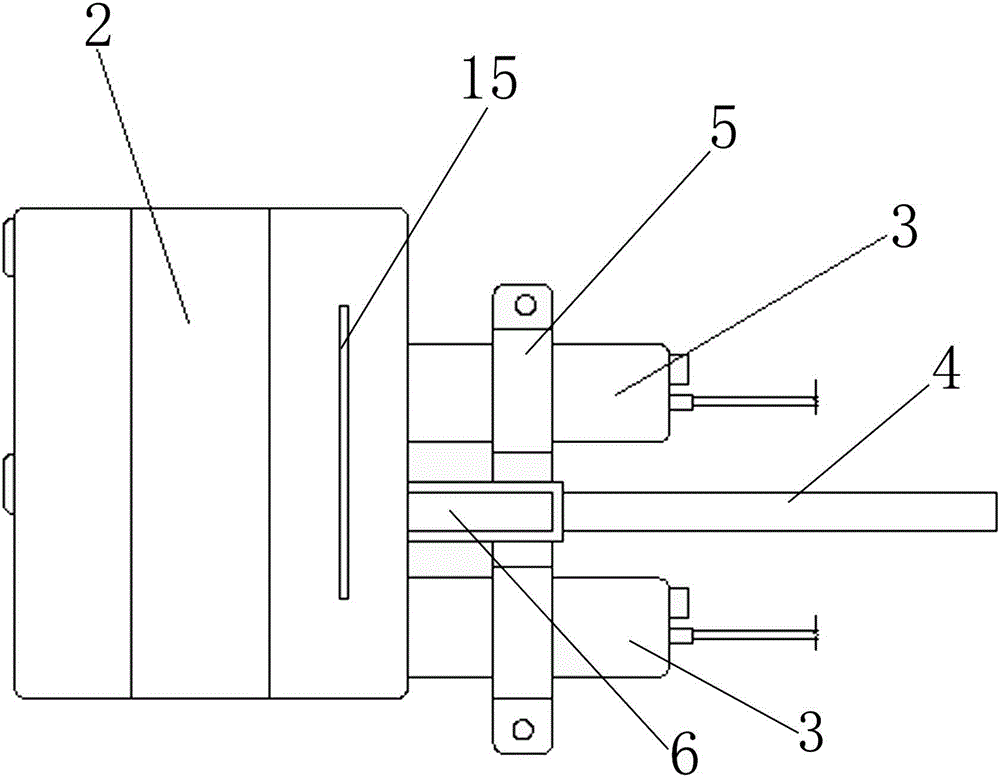

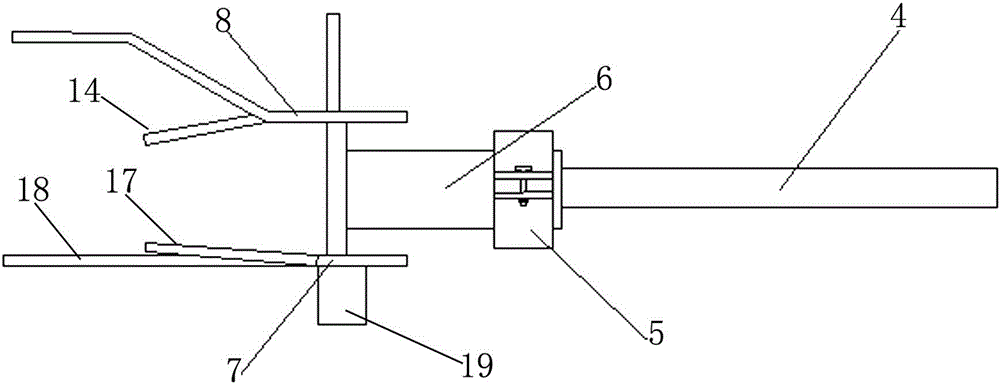

[0028] refer to Figure 1-5 , a slotting machine for aerated concrete blocks, including two refitted grinders 3 and a slotting machine fixing bracket 2, the bracket 2 includes a steel plate connector 6, and the front ends of the steel plate connector 6 are respectively welded with a protective plate 8 and the lower fixed plate 7, its rear end is provided with a handle 4, the steel plate connector 6 is provided with two polishing machine fixing rings 5, and the top of the upper protective plate 8 is provided with a handle 15; the described polishing machine 3 is not A protective cover is provided, and the original grinding wheel is replaced by a saw blade group composed of three hard alloy circular saw blades 9, which is the cutting part of the slotting machine. Spacers 10 are arranged between the circular saw bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com