Aircraft built-in engine installation structure and its moving assembly method

An installation structure and engine technology, applied in aircraft assembly, power plant arrangement/installation, aircraft parts, etc., can solve the problem that the convenience, safety, speed, and accuracy of aircraft built-in engine installation cannot meet the requirements of coordination, unity, and vertical integration. Problems such as complex conversion of hoisting product stations, etc., to achieve the effect of convenient operation and simple installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The aircraft built-in engine installation structure and its step-by-step assembly method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

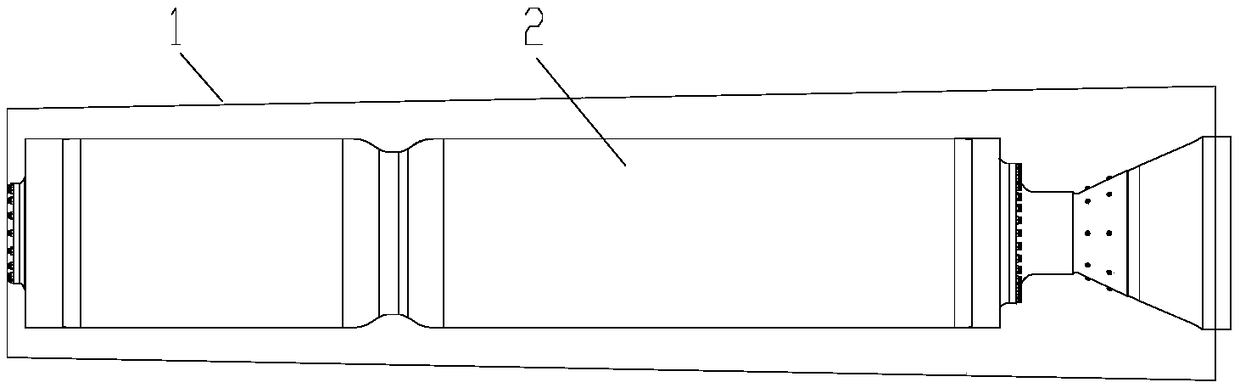

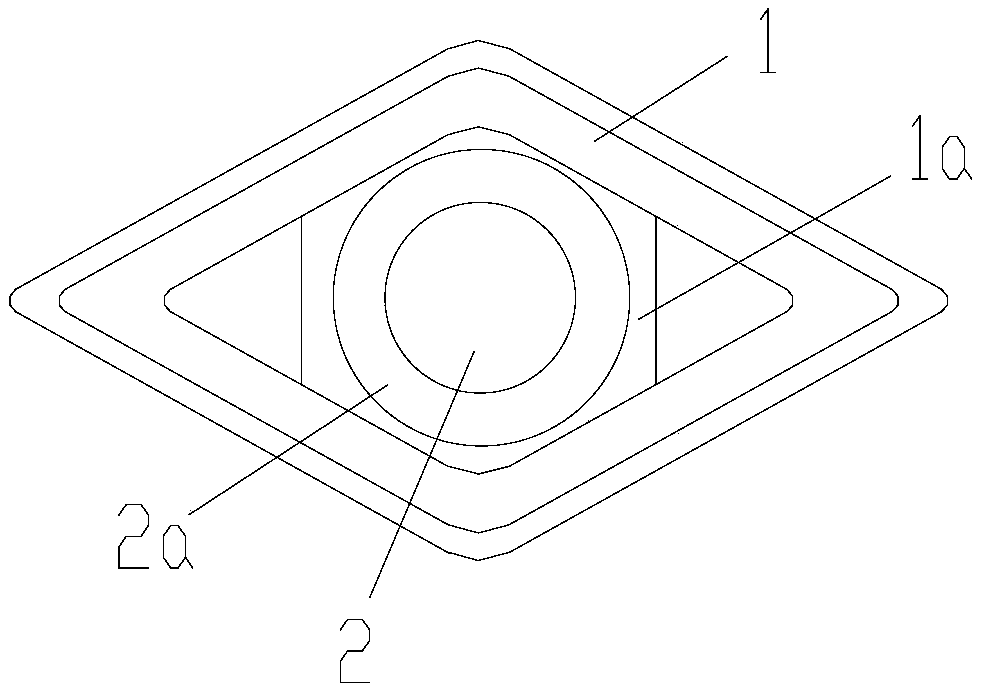

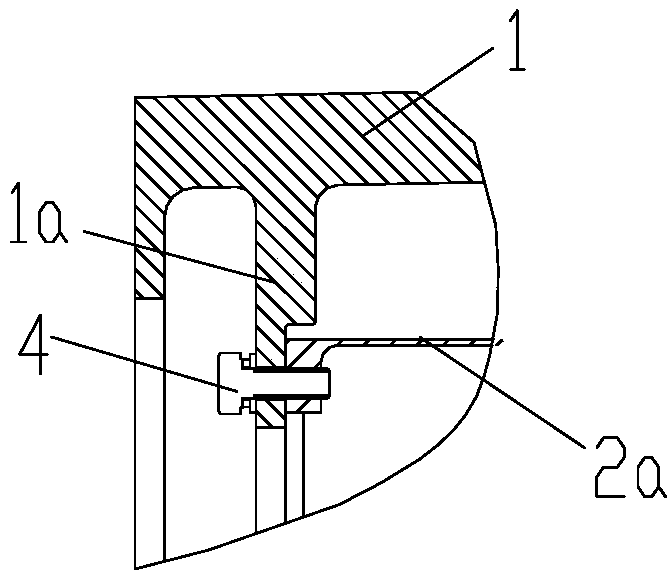

[0031] Such as Figure 1~5 As shown, the aircraft built-in engine mounting structure of the present invention includes a protective cover 1 as an aircraft load-bearing shell and an engine 2 fixedly installed in the inner cavity of the protective cover 1, and the protective cover 1 and the engine 2 are coaxially arranged. The front part of the protective cover 1 is integrally formed with an end face installation frame 1a, and the head of the engine 2 is provided with an end face connection frame 2a. Fitted and connected, so that the head of the engine 2 is axially fixed in the front cavity of the protective cover 1; the rear part of the protective cover 1 is integrally formed with the shaft section support frame 1b in an open structure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com