Clarification section temperature control device and method

A technology of a temperature control device and a temperature control method, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass furnace equipment, etc., can solve the problems of temperature difference in glass liquid, low temperature of glass incoming material, and different temperature in the clarification section, etc., to achieve Reduce the temperature difference between front and back, flexible power adjustment, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A temperature control method for a clarification section, comprising the following steps:

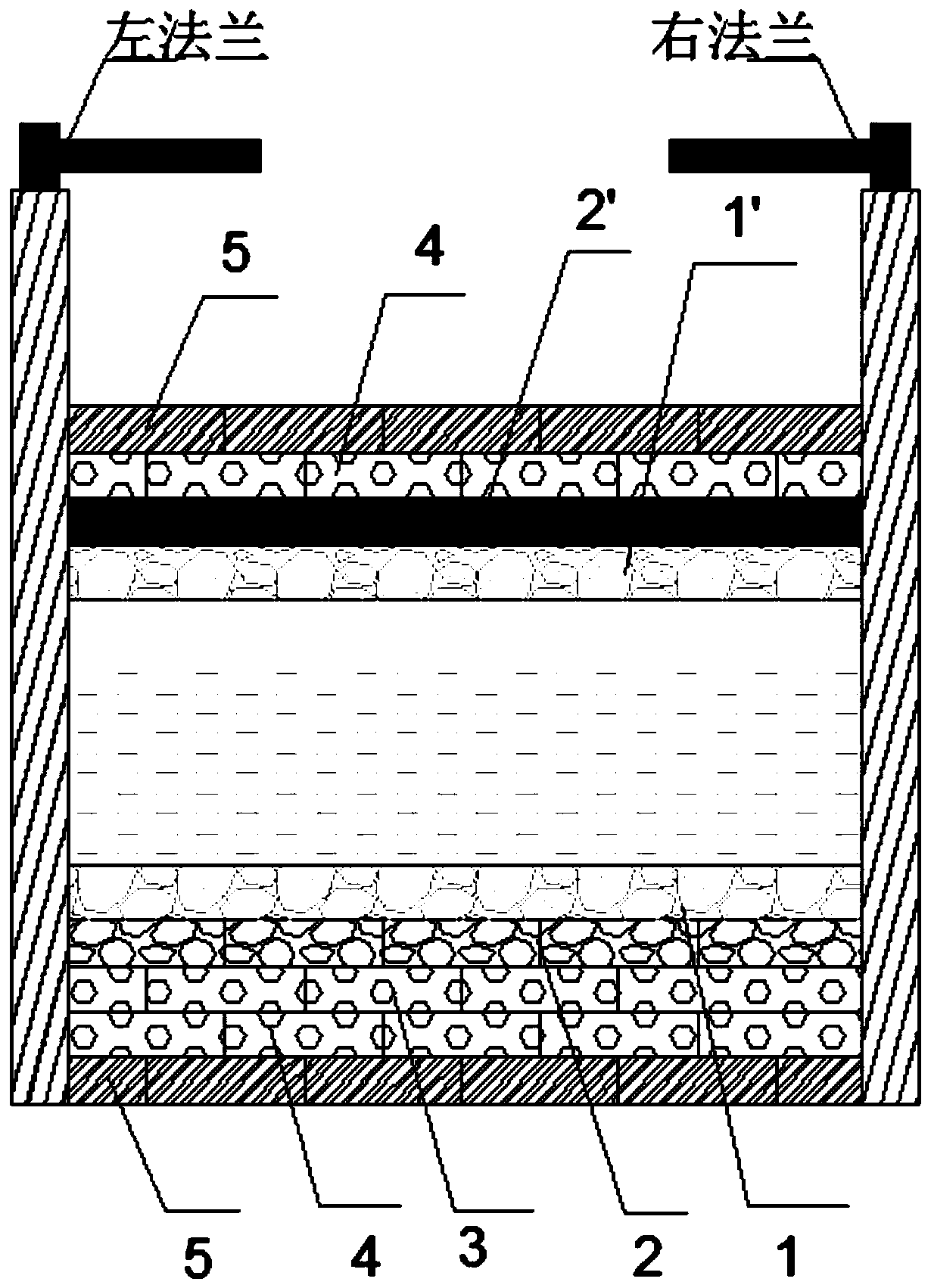

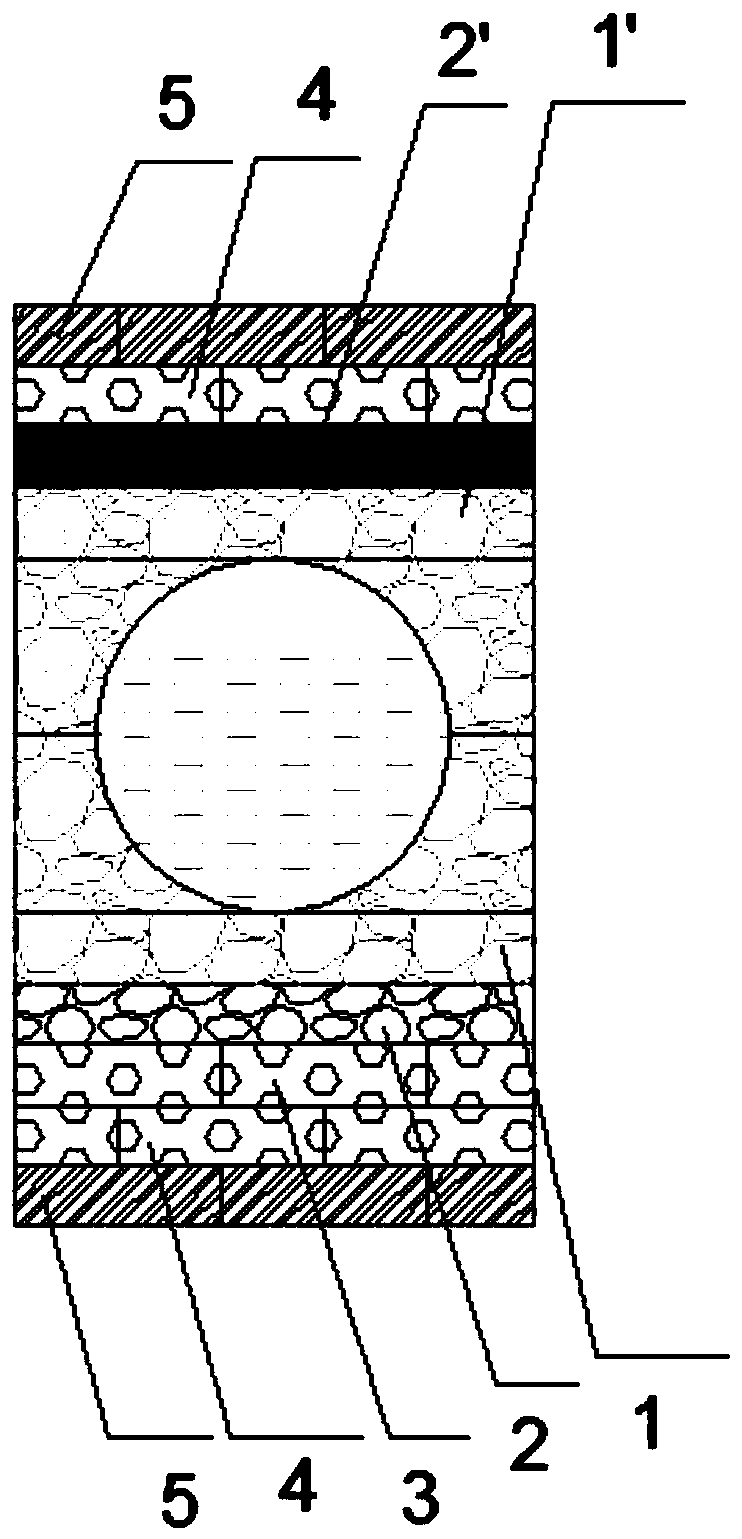

[0049] S1: Install the first U-shaped brick and the second U-shaped brick on the outer wall of the pipeline in the clarification section, and install a heating brick with an S-shaped platinum heating wire inside on the first U-shaped brick as an indirect heating system. The width is 10cm;

[0050] S2: Wrap the second thermal insulation layer and the first thermal insulation layer sequentially on the heating brick described in step S1 from the inside to the outside, and sequentially wrap the fourth thermal insulation layer, the third thermal insulation layer, and the second thermal insulation layer on the second U-shaped brick and the first insulation layer;

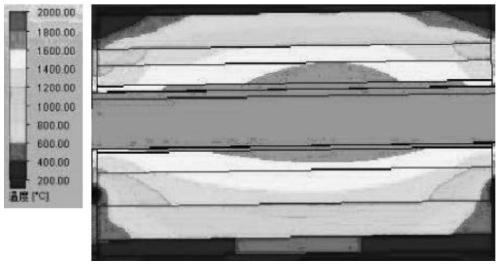

[0051] S3: Control the load power of the heating brick according to the temperature of different areas of the pipeline in the clarification section. When the temperature of the pipeline in the clarification section is 1450°C,...

Embodiment 2

[0053] A temperature control method for a clarification section, comprising the following steps:

[0054] S1: Install the first U-shaped brick and the second U-shaped brick on the outer wall of the pipeline in the clarification section, and install a heating brick with an S-shaped platinum heating wire inside on the first U-shaped brick as an indirect heating system. The width is 15cm;

[0055] S2: Wrap the second thermal insulation layer and the first thermal insulation layer sequentially on the heating brick described in step S1 from the inside to the outside, and sequentially wrap the fourth thermal insulation layer, the third thermal insulation layer, and the second thermal insulation layer on the second U-shaped brick and the first insulation layer;

[0056] S3: Control the load power of the heating bricks according to the temperature in different areas of the pipeline in the clarification section. When the pipeline temperature in the clarification section is 1500°C, con...

Embodiment 3

[0058] A temperature control method for a clarification section, comprising the following steps:

[0059] S1: Install the first U-shaped brick and the second U-shaped brick on the outer wall of the pipeline in the clarification section, and install a heating brick with an S-shaped platinum heating wire inside on the first U-shaped brick as an indirect heating system. The width is 20cm;

[0060] S2: Wrap the second thermal insulation layer and the first thermal insulation layer sequentially on the heating brick described in step S1 from the inside to the outside, and sequentially wrap the fourth thermal insulation layer, the third thermal insulation layer, and the second thermal insulation layer on the second U-shaped brick and the first insulation layer;

[0061] S3: Control the load power of the heating brick according to the temperature of different areas of the pipeline in the clarification section. When the temperature of the pipeline in the clarification section is 1550°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com