Steel bar truss floor deck

A technology of reinforced trusses and floor slabs, applied in the field of floor slabs, can solve the problems of long construction period, poor quality, cumbersome procedures, etc., and achieve the effects of fast construction progress, saving occupied area, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

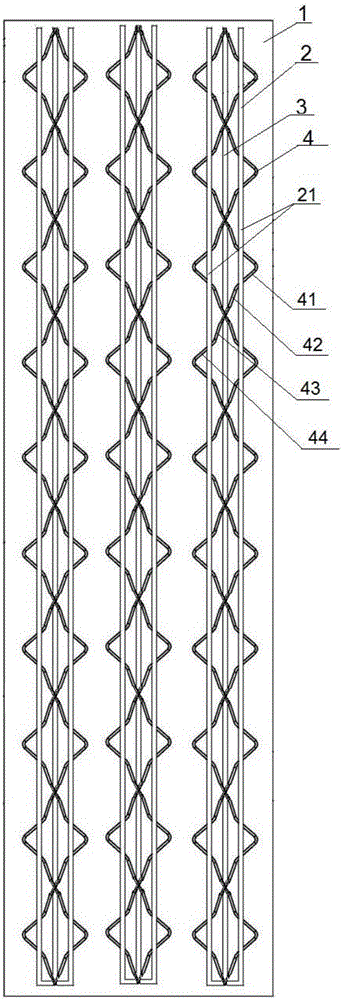

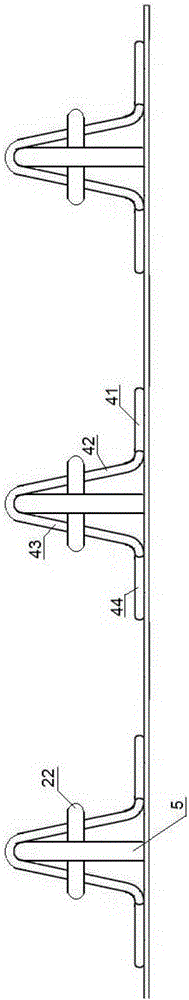

[0025] Such as Figure 1-2 As shown, each reinforcement assembly includes a lower chord 2 , an upper chord 3 and two web reinforcements 4 . There is a certain distance between the lower string member 2 and the top surface of the base plate 1 . The lower chord 2 includes two first steel bars 21 extending parallel to the length direction of the base plate 1 and a first connecting steel bar 22 , the first connecting steel bar 22 is connected to the first ends of the two first steel bars 21 . The upper chord reinforcement 3 is arranged parallel to the first reinforcement 21 , and the upper chord reinforcement 3 is arranged directly above the lower chord 2 , that is, in the middle of the two first reinforcements 21 .

[0026] Such as figure 1 and 2 As shown, each web reinforcement 4 is S-shaped, and the web reinforcement 4 extends from one end of the upper chord reinforcement 3 and the lower chord 2 to the other end, and the web reinforcement 4 is connected to the top surface of...

Embodiment 2

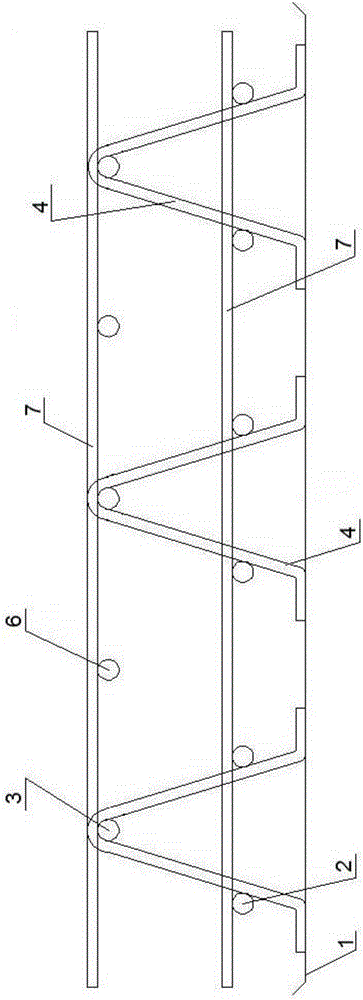

[0032] The difference between this embodiment and Embodiment 1 is that the steel bar assembly includes two lower chords 2 arranged from top to bottom, and the lowermost lower chord 2 has a certain distance from the top surface of the base plate 1, such as Figure 4 shown.

[0033] When utilizing the floor bearing plate of the steel bar truss of the present invention to install, comprise the following steps:

[0034] 1) According to the strength of steel bars designed on engineering drawings, the bearing capacity of the floor and the service life, calculate the steel bar models of the upper chord, lower chord and web reinforcement.

[0035] 2) Process the floor deck.

[0036] 3) Acceptance of materials entering the site: Sampling inspection is carried out on the qualified floor slabs to ensure that the steel bar type and structural dimensions of the floor slabs are correct, and check whether the welding points of the floor slabs are firm.

[0037] 4) Directly hoist the qualif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com