A kind of composite plate, production method and application of composite plate

A composite board and board technology, applied in the field of composite boards, can solve problems such as low utilization rate, low part conversion rate, energy consumption, etc., and achieve the effects of improving service life, high part conversion rate, and convenient installation and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

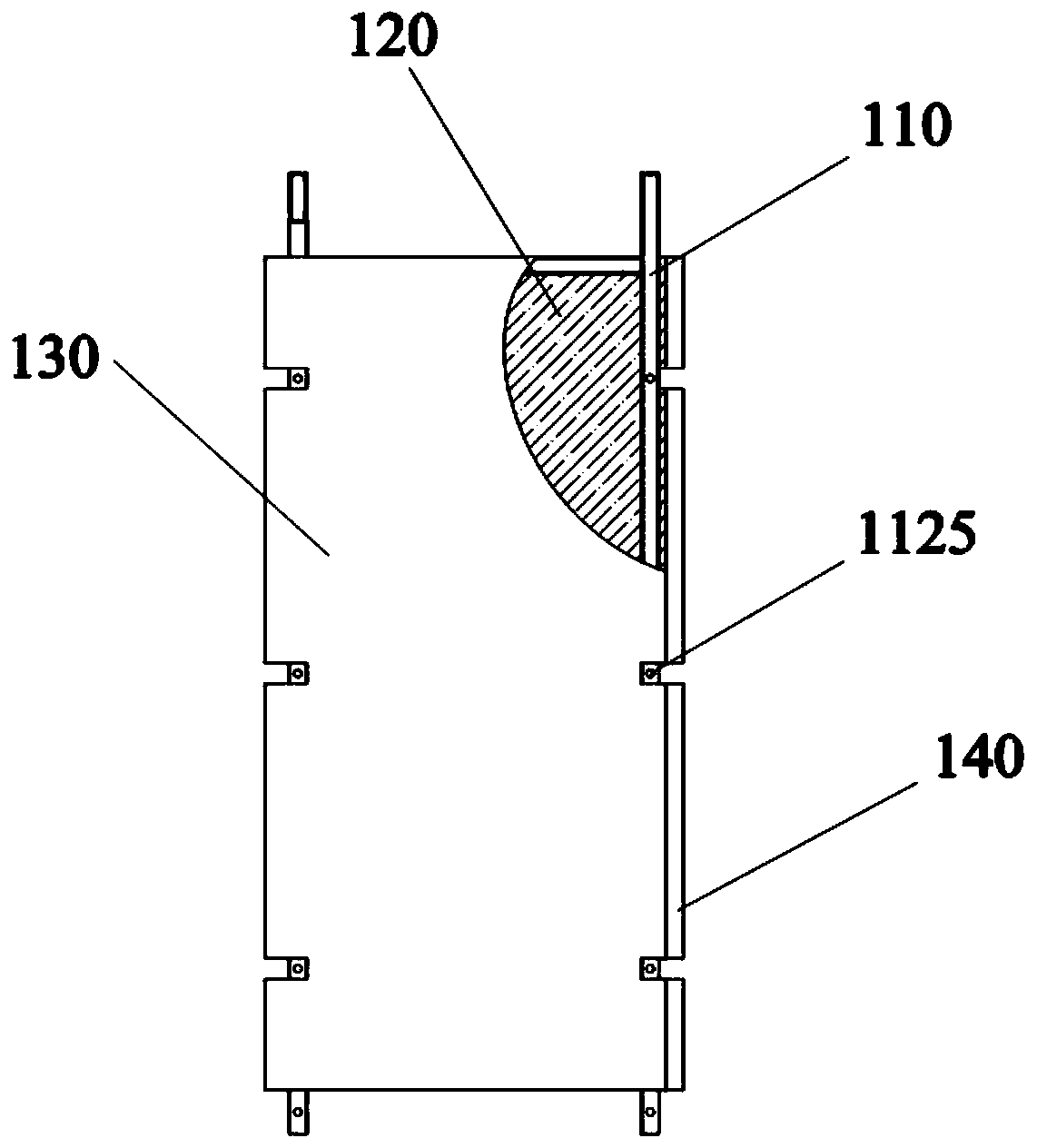

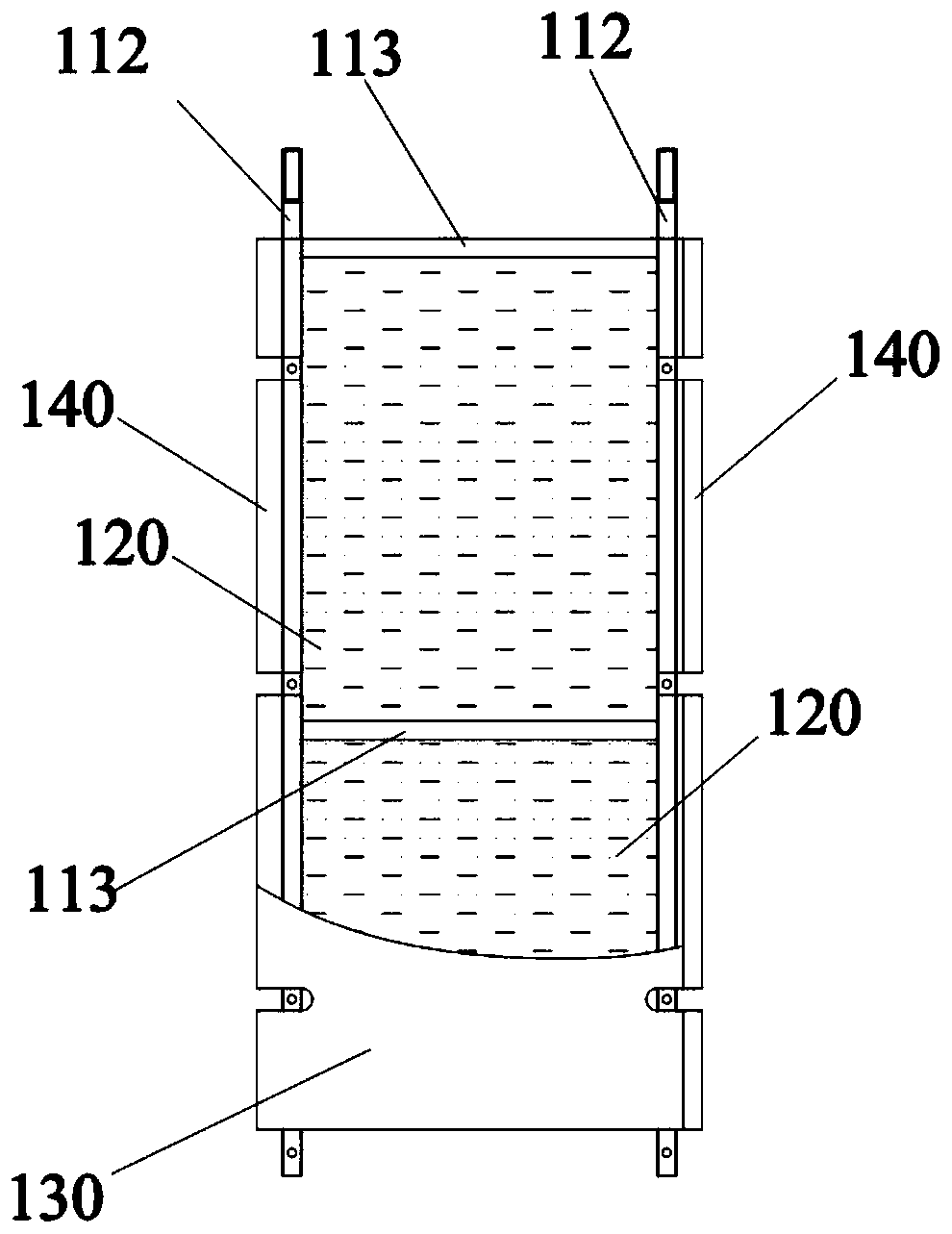

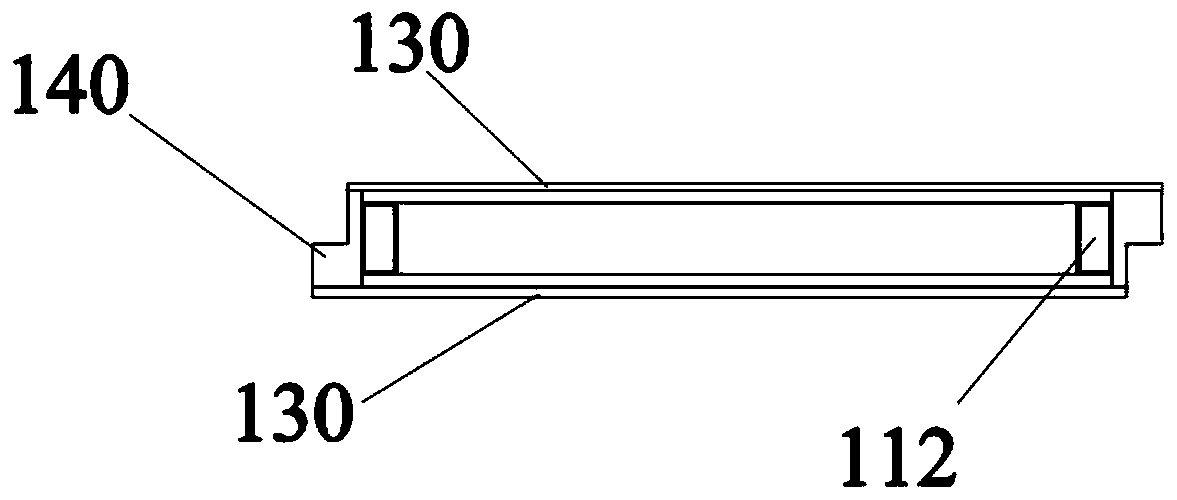

[0034] Such as Figure 1 to Figure 5 As shown, the composite panel provided by the present invention includes a light steel skeleton 110, a filling interlayer 120 and two fixing panels 130, the filling interlayer 120 is placed in the inner cavity of the light steel framework 110, and the two fixing panels 130 are installed in the light The front and back sides of the steel frame 110 fix the filled interlayer 120 in the light steel frame 110 .

[0035] As a possible implementation, the light steel skeleton 110 is a rectangular frame structure welded by rectangular steel pipes. The light steel skeleton 110 includes two longitudinal beams 112 and at least two cross beams 113. The two longitudinal beams 112 are arranged in parallel. 113 are arranged between the two longitudinal beams 112, and the two longitudinal beams 112 are provided with a plurality of plate connection holes 1125 penetrating through the longitudinal beams 112 for installation and fixing between adjacent composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com