Refrigerant filling machine and method for carrying out vacuum-pumping, leakage detecting and refrigerant filling by utilizing refrigerant filling machine

A filling machine and vacuuming technology, used in lighting and heating equipment, refrigerators, refrigeration and liquefaction, etc., can solve the problems of high professional proficiency, cumbersome operation process, hidden safety hazards, etc., to improve system reliability, The effect of prolonging the vacuuming time and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

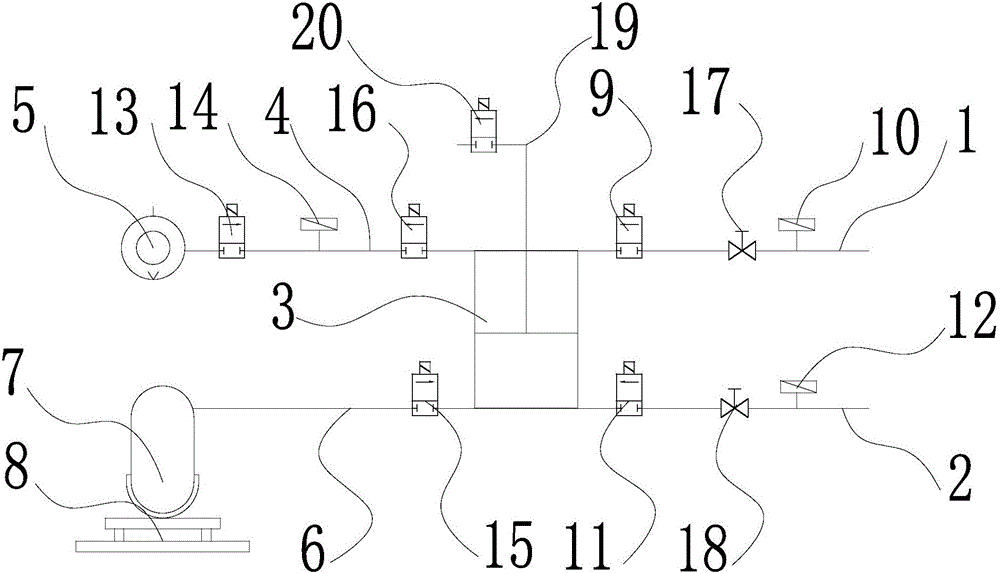

[0041] Such as figure 1 As shown, a refrigerant filling machine of the present invention includes a corresponding high-pressure pipe 1 and a low-pressure pipe 2 connected to the high and low-pressure ends of the refrigeration system, and the other ends of the high-pressure pipe 1 and the low-pressure pipe 2 are connected in parallel. On the interface of one end of the valve body pipeline 3, the other end of the valve body pipeline 3 is connected in parallel to the vacuum pipeline 4 and the refrigerant pipeline 6, and the other end of the vacuum pipeline 4 is connected to the vacuum pump 5 and the refrigerant pipeline 6. The other end is connected to the refrigerant storage cylinder 7. The refrigerant storage cylinder 7 is placed on the electronic scale 8. On the high-pressure pipeline 1, there are a high-pressure side solenoid valve 9 and a high-pressure side sensor 10 in series. The valve 9 is located on the high-pressure pipeline 1 close to the valve body pipeline 3, and a hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com