A portable stress detection device for in-service steel bridges based on magnetic flux technology

A stress detection and portable technology, which is applied in the direction of measuring device, measuring the change force of material magnetic property caused by applied stress, measuring force, etc., can solve the problem of difficult operation, difficult to reuse, internal force and deformation exceeding the limit and other problems, to achieve the effect of simple detection method, reliable detection results and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

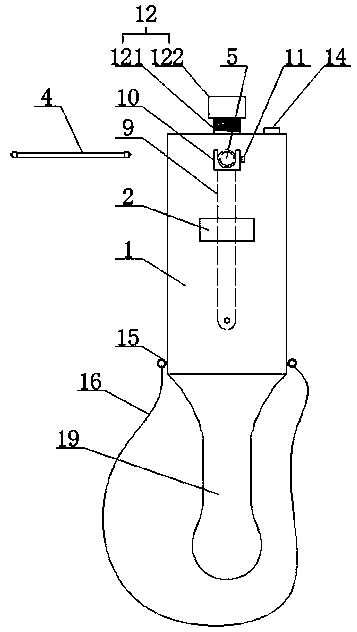

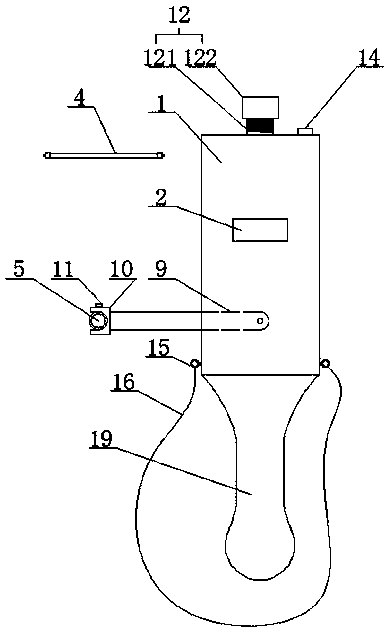

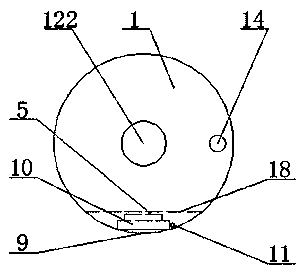

[0030] Figure 1 to Figure 9 A specific embodiment of the present invention is shown: a portable in-service steel bridge stress detection device based on magnetic flux technology, including a casing 1, a main control unit 2, a display screen 3, a magnetic induction coil 4, a Hall sensor 5 and a power module 6. The main control unit 2 is installed in the casing 1, the display screen 3 is embedded outside the casing 1, the magnetic induction coil 4 is connected to the power module 6 through the main control unit 2, and the main control unit 2. The strength of the applied magnetic field is controlled by the D / A card 7. The Hall sensor 5 is connected to the main control unit 2 through the A / D card 8. The main control unit 2 and the Hall sensor 5 are powered by the power module 6. The power module 6 is a rechargeable power supply, and the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com