Virtual simulation test method

A test method and virtual simulation technology, which is applied in the field of virtual simulation testing, can solve problems such as difficult automation, cumbersome process, and heavy workload, and achieve the effects of improving use efficiency, reducing technical requirements, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The goal of testability work is to ensure that systems and equipment meet specified testability requirements to improve system and equipment readiness and mission success, reduce requirements for maintenance manpower and other resources, and reduce life cycle costs. Therefore, the main focus of testability prediction is the indicators of fault detection rate (FDR) and fault isolation rate (FAR).

[0034] The virtual simulation test method of the present invention comprises constructing a test model and carrying out fault analysis to the model constructed:

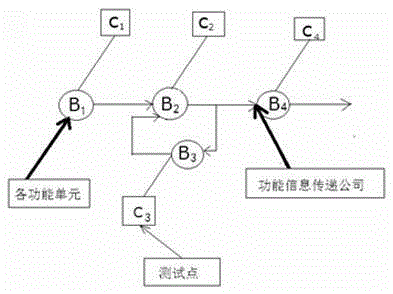

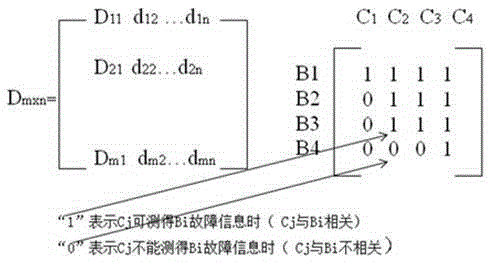

[0035] The basic construction elements of the model include functional modules (module), test points (lest point), tests (test), fault propagation relations (dependencies), and mode conversion switches (switches). The modeling steps are as follows:

[0036] 1) Collect and be familiar with all useful system documents: collect data about system operation manuals, design circuit diagrams, component reliability data indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com