Brake drum comprising an annular body spaced away from the friction ring

A technology of ring components and brake drums, which is applied in the direction of brake types, brake parts, brake drums, etc., can solve the problems of more expensive and complicated implementation of brake drums, and achieve the effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

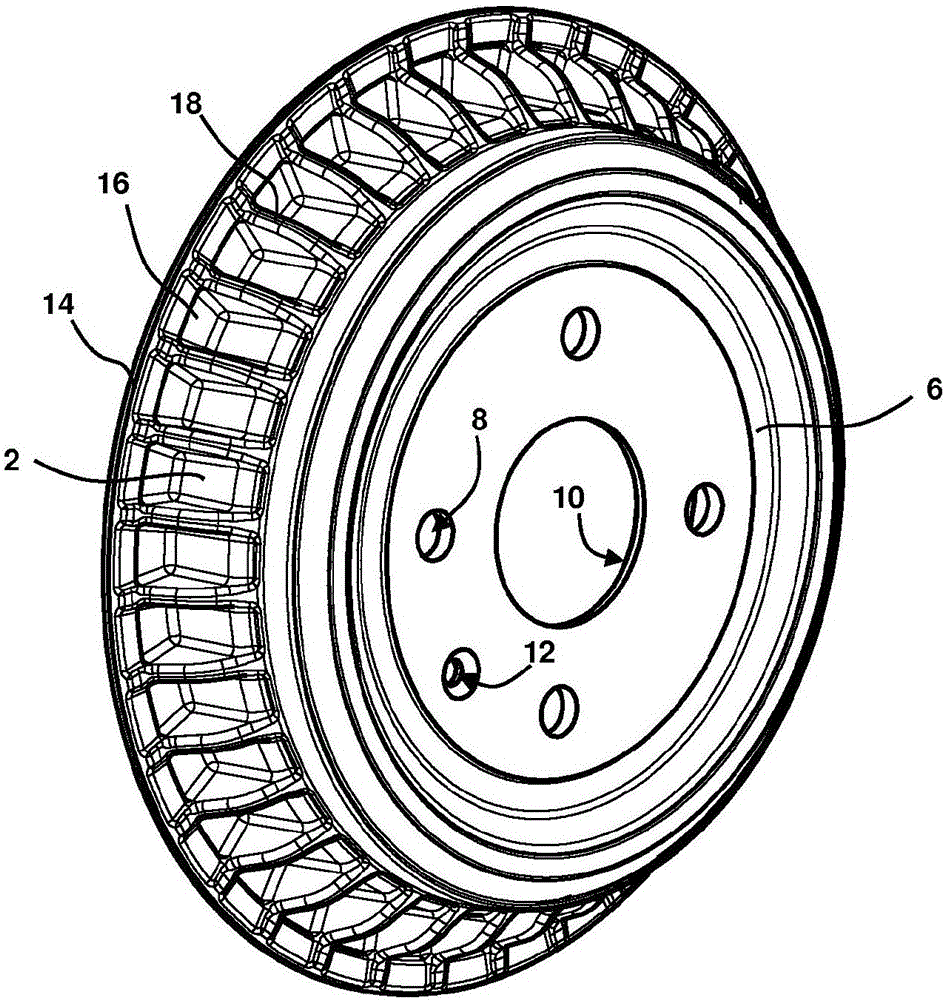

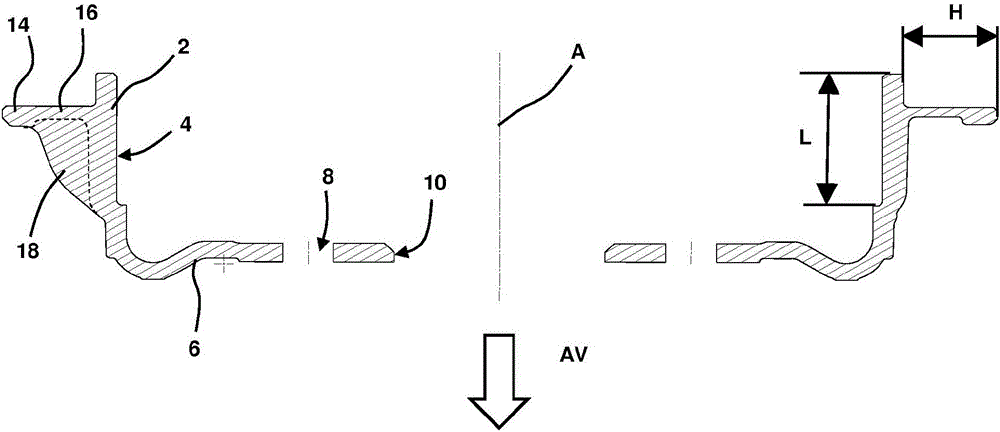

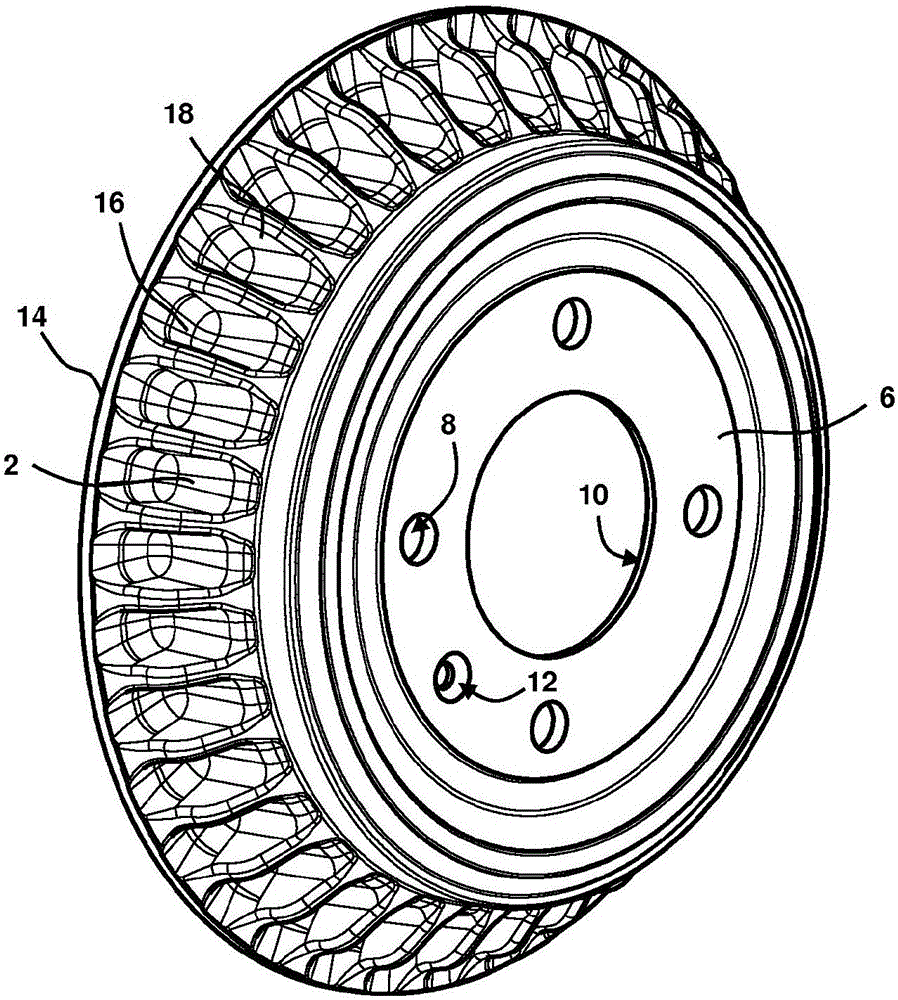

[0027] figure 1 and figure 2 A brake drum is shown comprising a circular ring 2 having a cylindrical inner friction surface 4 receiving brake member pressure, said inner friction surface being centered on a main axis A as a center.

[0028] As indicated by the arrows "AV", the front side of the ring 2 is connected by means of a bend to a radial flange 6 comprising a central transverse planar part with four perforations 8, The four perforations receive the fixing screws that secure the wheel to the hub; and the supplementary perforations 12 that receive the tightening screws that tighten the brake drum on the hub.

[0029] A central hole 10 in the center of the radial flange 6 implements the centering of the brake drum on the hub.

[0030] An annular member 14 arranged on the outside of the ring 2 is coupled to it by a continuous radial wall 16 of reduced thickness relative to this annular member, said radial wall lying in a transverse plane, said A transverse plane is adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com