Treatment method for improving applicability of burley tobaccos in flue-cured tobaccos

A technology of flue-cured cigarettes and processing methods, which is applied in the field of processing to improve the applicability of burley tobacco in flue-cured cigarettes, and can solve the problems of heavy smell of burley tobacco, difficulty in being used in flue-cured cigarette formulas, and large inventory of burley tobacco. problem, to achieve the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

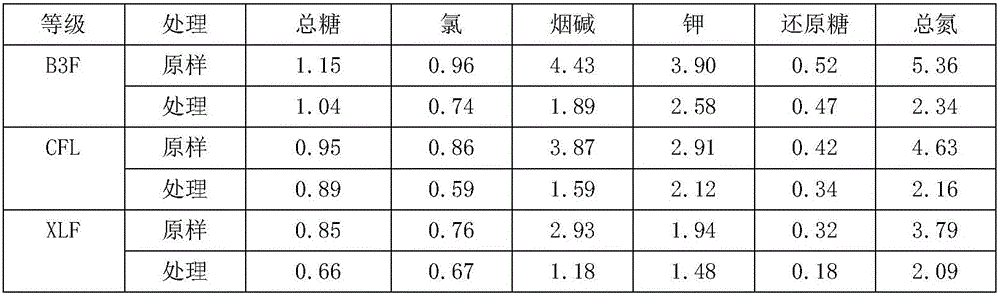

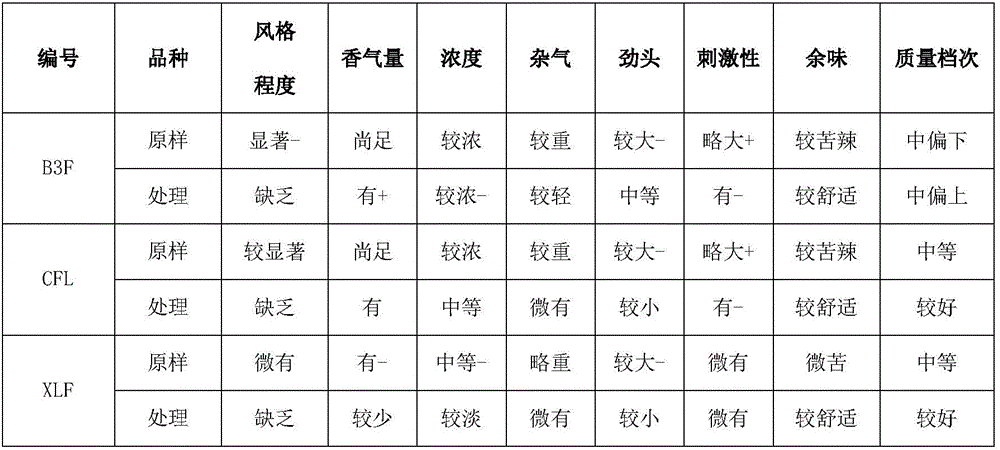

Embodiment 1

[0019] Using the existing stock of Burley Tobacco B3F in China Tobacco Hubei as the material, shake the tobacco loose, put it into a special bamboo basket, and vacuum it for 30 minutes before taking it out. According to the solid-liquid ratio of 1:4, put the burley tobacco after vacuum rehydration together with the bamboo basket into the 8% feed liquid, which contains 2.5% citric acid, 2% malic acid, and 3.5% lactic acid , Soak for 15 minutes, then remove and put in a centrifuge for dehydration. The dehydrated Burley tobacco enters the roasting machine and is baked in two stages. The first stage is baked at 140°C for 10 minutes, 150°C and 160°C for 5 minutes each, and the second stage is 110-120°C. Bake until the water content is about 20%, and then shred. The shredded Burley tobacco is fed twice according to 3% of the weight of shredded tobacco, and the concentration of the feed liquid is 6%, of which 0.5% is indole, 1.5% is damascenone, 1.5% is fennel oil, and 2% is fig ext...

Embodiment 2

[0021] Using the existing stock of China Tobacco Hubei Burley Tobacco CFL as the material, shake the tobacco loose, put it into a special bamboo basket, and take it out after 25 minutes of vacuum rehydration. According to the solid-to-liquid ratio of 1:4, put the burley tobacco after vacuum rehydration together with the bamboo basket into a 6.5% feed liquid, which contains 2% citric acid, 1.5% malic acid, and 3% lactic acid , Soak for 10 minutes, then remove and put in a centrifuge for dehydration. The dehydrated Burley tobacco enters the roasting machine and is baked in two stages. The first stage is baked at 140°C for 10 minutes, 150°C and 160°C for 5 minutes each, and the second stage is 110-120°C. Bake until the water content is about 20%, and then shred. The shredded Burley tobacco is fed twice according to 3% of the weight of shredded tobacco, and the concentration of the feed liquid is 6%, of which 0.5% is indole, 1.5% is damascenone, 1.5% is fennel oil, and 2% is fig ...

Embodiment 3

[0023] Using the existing stock of Burley tobacco XLF in Hubei China Tobacco as the material, shake the tobacco loose, put it into a special bamboo basket, and vacuum it for 20 minutes before taking it out. According to the solid-to-liquid ratio of 1:4, put the vacuum-rehydrated Burley tobacco together with bamboo baskets into a 5% feed liquid, which contains 1.5% citric acid, 1.5% malic acid, and 2% lactic acid. , Soak for 12 minutes, then remove and put in a centrifuge for dehydration. The dehydrated Burley tobacco enters the roasting machine and is baked in two stages. The first stage is baked at 140°C for 10 minutes, 150°C and 160°C for 5 minutes each, and the second stage is 110-120°C. Bake until the water content is about 20%, and then shred. The shredded Burley tobacco is fed twice according to 3% of the weight of shredded tobacco, and the concentration of the feed liquid is 6%, of which 0.5% is indole, 1.5% is damascenone, 1.5% is fennel oil, and 2% is fig extract. %...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com