Applications of carboxymethyl chitosan to preparation or screening of products for antiallergic treatment

A carboxymethyl chitosan, anti-allergic technology, applied in allergic diseases, medical preparations containing active ingredients, organic active ingredients, etc., can solve the problem of undisclosed anti-allergic and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

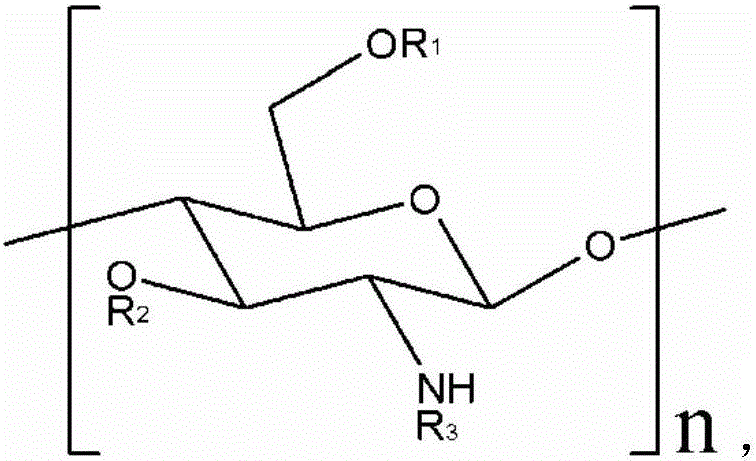

[0024] In this embodiment, carboxymethyl chitosan with a number average molecular weight of 2000 was prepared.

[0025] The carboxymethyl chitosan raw material with higher viscosity-average molecular weight is degraded with hydrogen peroxide, the viscosity-average molecular weight of the carboxymethyl chitosan raw material with higher viscosity-average molecular weight is 30W, and the carboxymethyl substitution degree is 0.8~1.3, Wherein, O means that the carboxymethyl substitution degree is 0.7-1.0, and the N-position substitution degree is not more than 0.3.

[0026] The process of hydrogen peroxide degradation is: adding hydrogen peroxide to carboxymethyl chitosan with higher viscosity-average molecular weight under stirring conditions for degradation reaction, adding alkali during the degradation reaction to make the pH of the reaction system be 8.2 until the viscosity of the reaction system is At 80cp, sodium sulfite was added to stop the reaction. In the degradation rea...

Embodiment 2

[0029] Carboxymethyl chitosan with a number average molecular weight of 8000 was adopted in the present embodiment.

[0030] The carboxymethyl chitosan raw material with higher viscosity-average molecular weight is degraded with hydrogen peroxide, the viscosity-average molecular weight of the carboxymethyl chitosan raw material with higher viscosity-average molecular weight is 40W, and the carboxymethyl substitution degree is 0.8~1.3, Wherein, O means that the carboxymethyl substitution degree is 0.7-1.0, and the N-position substitution degree is not more than 0.3.

[0031] The process of hydrogen peroxide degradation is: adding hydrogen peroxide to carboxymethyl chitosan with higher viscosity-average molecular weight under stirring conditions for degradation reaction, adding alkali in the degradation reaction process so that the pH of the reaction system is 8.5, until the viscosity of the reaction system is At 110cp, sodium sulfite was added to stop the reaction. In the degr...

Embodiment 3

[0034] Carboxymethyl chitosan with a number average molecular weight of 15,000 is used in this embodiment.

[0035] The carboxymethyl chitosan raw material with higher viscosity average molecular weight is degraded with hydrogen peroxide, the viscosity average molecular weight of the higher carboxymethyl chitosan raw material with viscosity average molecular weight is 55W, and the carboxymethyl substitution degree is 0.8~1.3, Wherein, O means that the carboxymethyl substitution degree is 0.7-1.0, and the N-position substitution degree is not more than 0.3.

[0036] The process of hydrogen peroxide degradation is: adding hydrogen peroxide to carboxymethyl chitosan with higher viscosity-average molecular weight under stirring conditions for degradation reaction, adding alkali during the degradation reaction to make the pH of the reaction system be 8.2 until the viscosity of the reaction system is Add sodium sulfite at 120cp to stop the reaction. In the degradation reaction, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com