Polycarboxylic acid water reducer reaction stirring kettle convenient to heat and cool

The technology of a water reducing agent and stirring tank is applied in the field of polycarboxylate water reducing agent reaction stirring tank, which can solve the problems of single function, dangerous operation process, low production efficiency, etc., so as to improve economic benefits, reduce maintenance costs, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

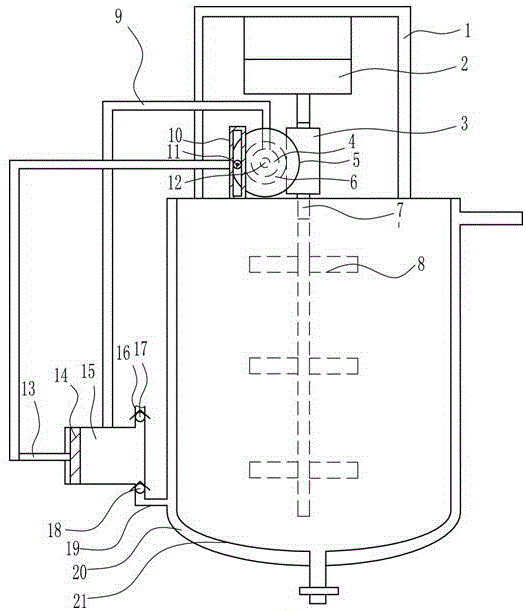

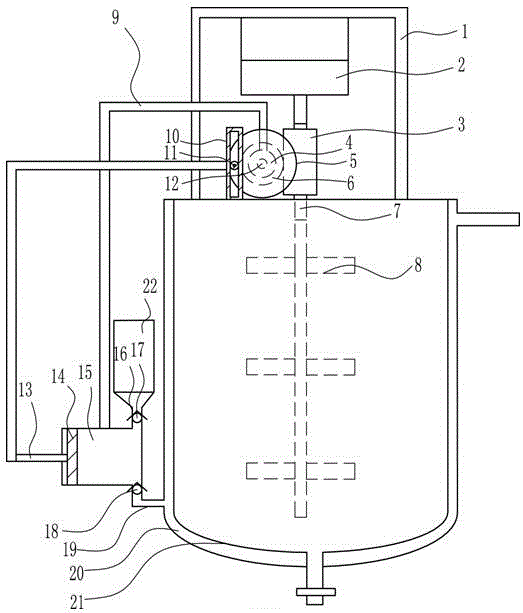

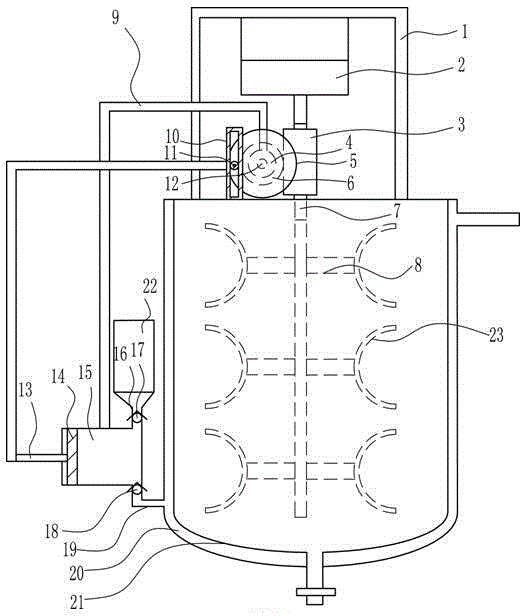

[0022] A polycarboxylate superplasticizer reaction stirred tank that is convenient for heating and cooling, such as Figure 1-3 As shown, it includes a first bracket 1, a motor 2, a worm screw 3, a bearing housing 4, a runner 5, a worm wheel 6, a first rotating shaft 7, a stirring rod 8, a second bracket 9, a moving frame 10, a roller 11, a first Two rotating shafts 12, left and right moving rods 13, piston 14, cylinder body 15, liquid inlet pipe 16, first one-way valve 17, second one-way valve 18, connecting pipe 19, cavity 20 and reaction kettle 21; first bracket 1 is connected to the top of the reaction kettle 21 by welding, the motor 2 is installed directly below the middle part of the first bracket 1 by screws, the output shaft of the motor 2 is connected to the first rotating shaft 7 through a coupling, and the worm 3 is connected to the second shaft by a flat key. On a rotating shaft 7, the lower end of the first rotating shaft 7 is connected with a stirring rod 8 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com