Continuous roller type cold bending forming method for sharp-angled rectangular tube

A technology of cold forming and rectangular tubes, which is applied in the field of metal material pressure processing, can solve the problems of poor pressure control, insufficient stability, and poor welding quality, and achieve high forming accuracy, improved forming accuracy, and stable forming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

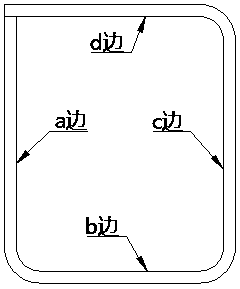

[0040] A continuous roll-type cold-bending forming method for a pointed rectangular tube, specifically comprising the following steps:

[0041] (1) Feed the strip steel billet into the first frame of the cold roll forming unit, then bend side a upwards and form a 9-14° angle with the horizontal bottom line, keep side b horizontal, and bend side d upwards and meet the horizontal bottom line at the same time It is 12-17°, and then enters the next process.

[0042] (2) Send the strip steel deformed by the first pass into the second frame, continue to deform on the basis of the first pass, bend side a upwards and form 21-26° with the horizontal bottom line, and keep side b At the same time, bend the d side upwards and form a 26-31° angle with the horizontal bottom line, and then enter the next process.

[0043] (3) Send the strip deformed by the second pass into the third rack, bend side a upwards and form a 36-41° angle with the horizontal bottom line, keep side b horizontal, an...

Embodiment approach 1

[0053] The steel strip in this embodiment is a hot-rolled coil with a width of 468.74 mm, a thickness of 6 mm, and unlimited length after slitting, and the brand name is 09CuPTiRE-A.

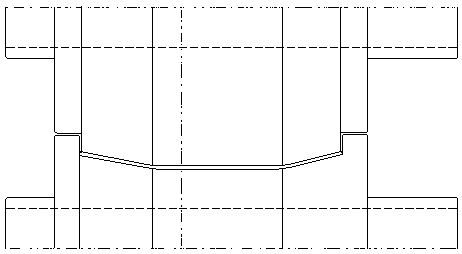

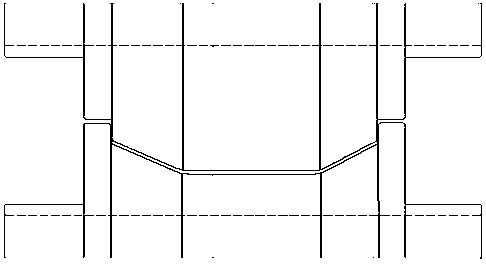

[0054] as attached figure 2 ~ attached Figure 12 shown

[0055] The first pass to the third pass: mainly the part of the left side (a side) and the top side (d side) is formed, and the bending angle of the left side (a side) is: 11 ° - 23 ° - —38°; the bending angles of the top edge (d side) are: 14°—28°—46°.

[0056] The 4th pass to the 7th pass: mainly the part of the left side (a side) and the right side (c side) is formed, and the bending angle of the left side (a side) is: 53 ° - 68 ° ——80°—88°; the bending angles of the right side (side c) are: 12°—27°—45°—66°; the top side (side d) is not bent.

[0057] The 8th pass: mainly the partial molding of the top side (d side), the top side (d side) is bent upwards and forms 105° with the c side, and the left side (a side) and right side (c ...

Embodiment approach 2

[0062] The steel strip in this embodiment is a hot-rolled coil with a width of 468.74 mm, a thickness of 6 mm, and unlimited length after slitting, and the brand name is 09CuPTiRE-A.

[0063] as attached figure 2 ~ attached Figure 12 shown

[0064] The first pass to the third pass: mainly the part of the left side (a side) and the top side (d side) is formed, and the bending angle of the left side (a side) is: 9 ° - 21 ° - —36°; the bending angles of the top edge (d side) are: 12°—26°—49°.

[0065] The 4th pass to the 7th pass: mainly the part of the left side (a side) and the right side (c side) is formed, and the bending angle of the left side (a side) is: 51 ° - 66 ° ——78°——89°; the bending angles of the right side (side c) are: 10°—25°—43°—69°; the top side (side d) is not bent.

[0066] The 8th pass: It is mainly the partial molding of the top edge (d edge), the top edge (d edge) is bent upwards and forms 108 with the c edge, and the left edge (a edge) and the right...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com