Steel box girder unit part stiffening rib welding method

A welding method and single-element technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as weld appearance quality defects, long welding cycle of single elements, and affecting production cycle, etc., to achieve good forming effect, Lightweight, time- and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] A method for welding steel box girder unit stiffeners, comprising the following steps:

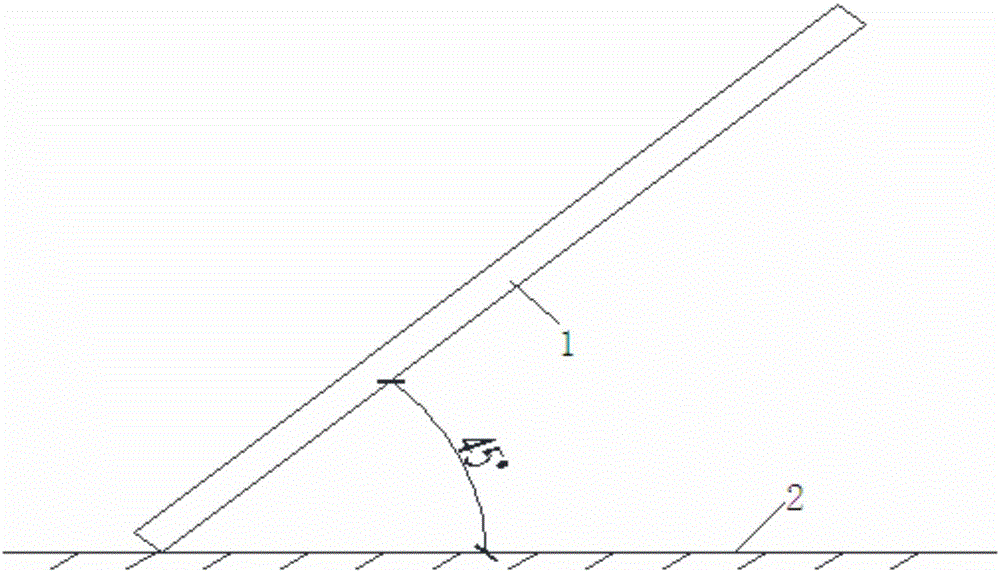

[0024] S1. If figure 1 As shown, the welded tire frame 1 of the steel box girder unit 3 is set so that the operating surface and the horizontal ground 2 form an angle of 45°;

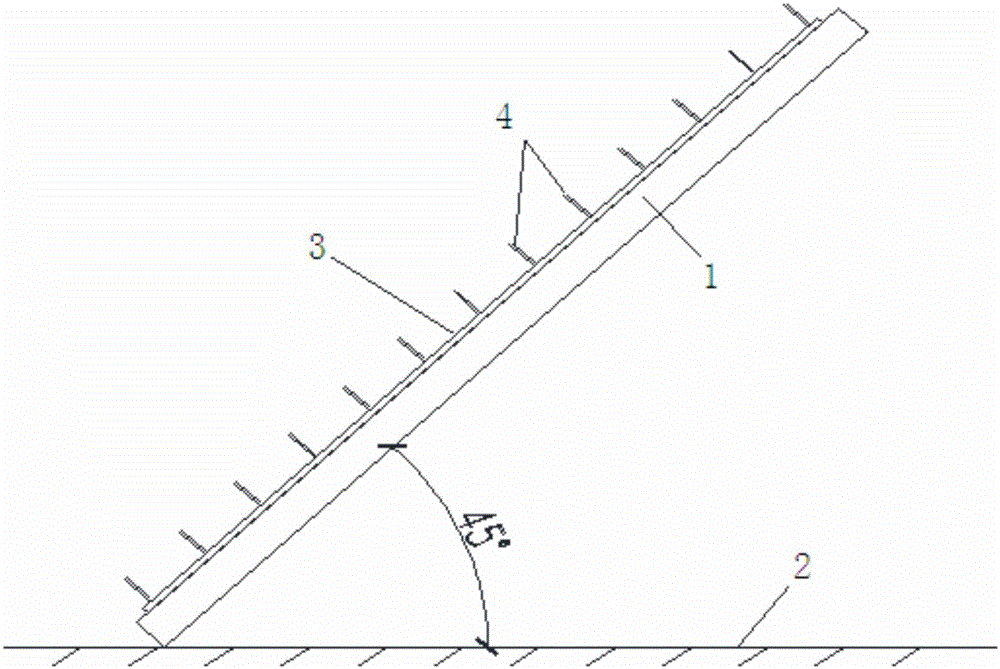

[0025] S2. If figure 2 As shown, the stiffener 4 and the steel box girder unit 3 are fixed by spot welding, and the steel box girder unit 3 is pasted on the welded tire frame 1;

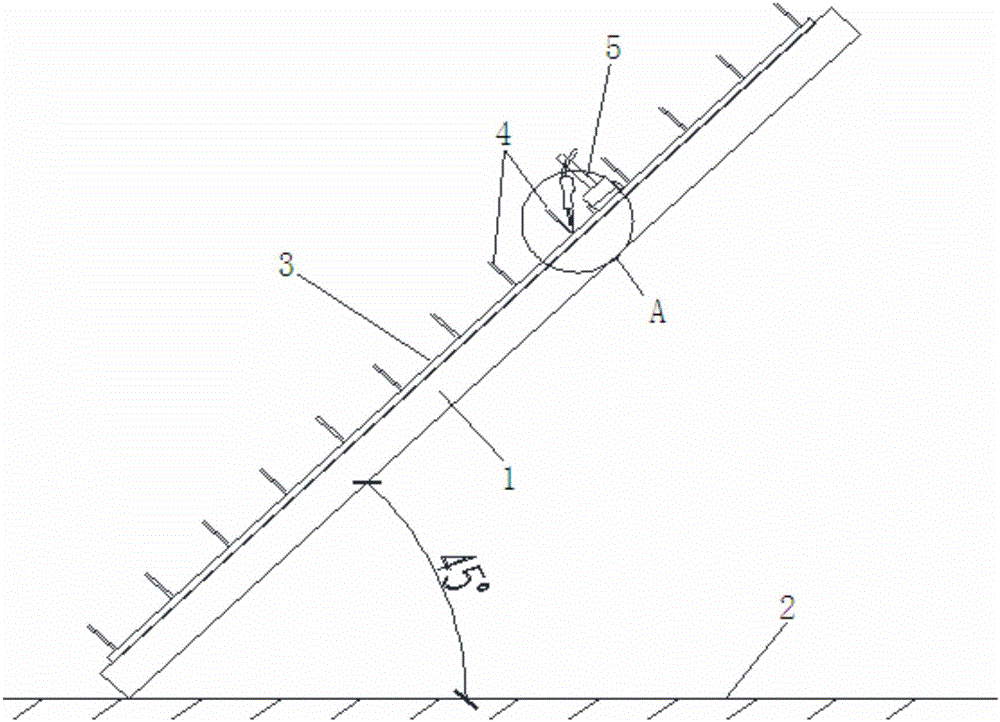

[0026] S3. If image 3 and Figure 4 shown, will have a CO 2 The welding trolley 5 protecting the welding torch 6 is placed on the steel box girder unit 3, and the CO 2 Protect the protective sleeve on the torch 6 so that the CO 2 The conductive tip at the end of the protective welding torch 6 is exposed, and the CO 2 The welding wire 7 on the protective welding torch 6 is aligned with the weld bead,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com