Filling method for friction stir welding keyhole

A technology of friction stir welding and filling method, applied in the field of friction stir welding, can solve the problems of high residual stress, many pores and complex structure at the fusion welding seam, and achieve the effect of good connection effect and high filling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

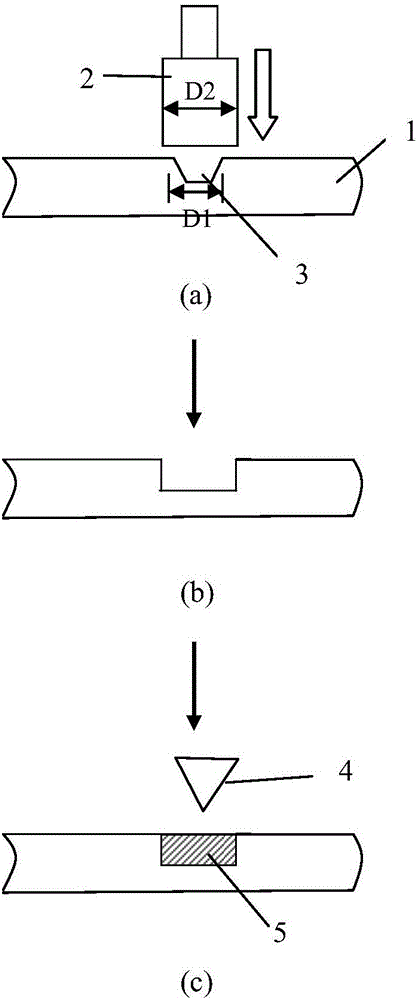

[0034] A filling method of friction stir welding keyhole, the schematic diagram of the filling process is as follows figure 1 shown, including the following steps:

[0035] (1) Reaming the keyhole 3. The schematic diagram of the reaming process is shown in Figure (a). The alloy drill bit 2 is used to process the keyhole 3 into a cylindrical drill hole. According to the maximum diameter D1 of the keyhole, select the corresponding Alloy drill bit 2, the diameter D2 of alloy drill bit 2 is greater than D1 by more than 2mm, and entered into the cad model library. The depth is more than 2mm greater than the depth of the keyhole, to ensure that the drilling area completely covers the keyhole 3, and the schematic diagram of the state after reaming is shown in Figure (b);

[0036] (2) According to the cad model of the alloy drill bit 2 of D2 size entered in advance, convert it into an stl model, perform positioning, determine the manufacturing depth, define the scanning path, and fin...

Embodiment 2

[0039] A filling method of friction stir welding keyhole, the schematic diagram of the filling process is as follows figure 1 shown, including the following steps:

[0040] (1) Reaming the keyhole 3. The schematic diagram of the reaming process is shown in Figure (a). The alloy drill bit 2 is used to process the keyhole 3 into a cylindrical drill hole. According to the maximum diameter D1 of the keyhole, select the corresponding Alloy drill 2, alloy drill diameter D2 is greater than D12mm, and entered into the cad model library, when the surface wear caused by alloy drill 2 repeated use, re-measure the size of alloy drill 2, and update the cad model, the drilling speed of alloy drill 2 is 3000r / min, the diameter of the completed drilling hole is greater than the maximum diameter D1 of the keyhole by more than 2mm, and the depth of the drilling hole is greater than the depth of the keyhole by more than 2mm, ensuring that the drilling area completely covers the keyhole 3. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com