Plastic pipe cutting device with receiving barrel

A cutting device and plastic pipe technology, applied in metal processing, etc., can solve problems such as poor automation, low cutting efficiency, and reduced cutting quality, and achieve the effects of easy collection, avoiding cutting deviation, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

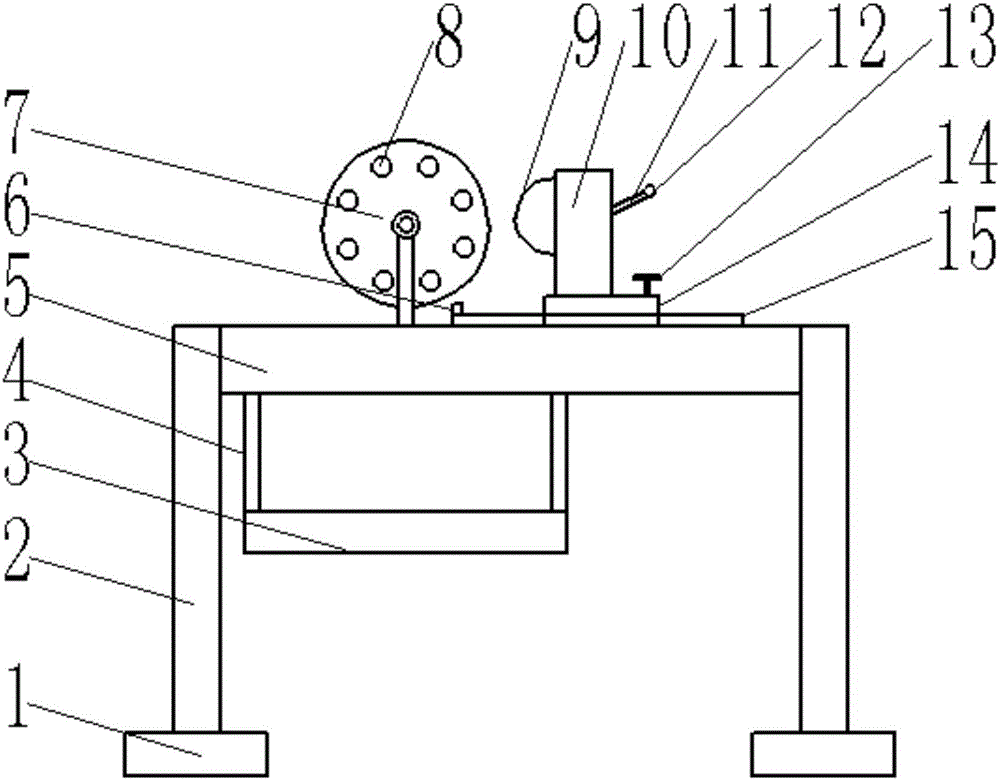

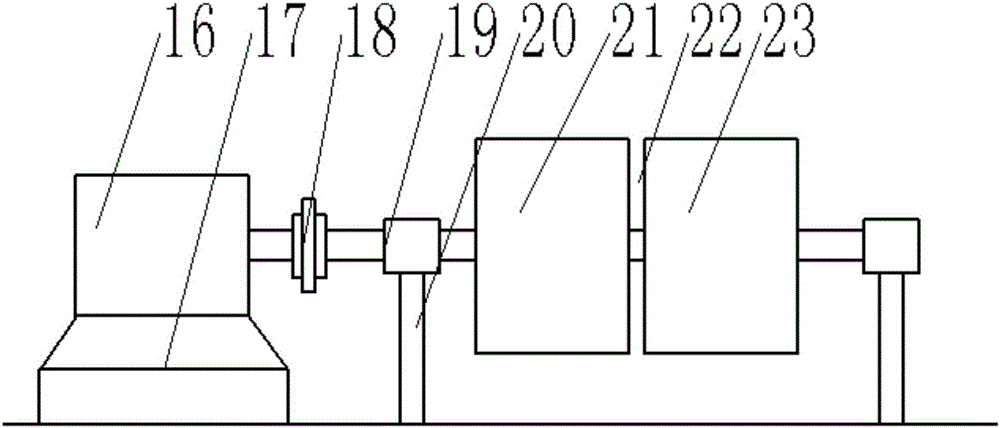

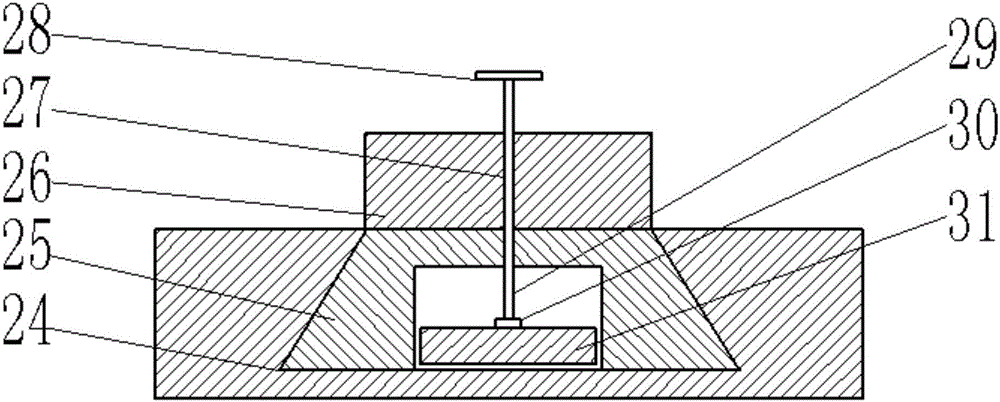

[0018] see Figure 1-4 , a plastic pipe cutting device with a receiving bucket, comprising a workbench 5, a support device 7 and a cutting knife 9; two ends of the workbench 5 are provided with support legs 2, and the bottom of the support legs 2 is provided with a bottom plate 1 , used to increase the contact area of the supporting legs 2, and then support the workbench 5; the support device 7 is arranged on the left part of the upper surface of the workbench 5, and the support device 7 is composed of a motor 16, a bearing 17, a shaft coupling 18, Rotating shaft 19, pillar 20, first support block 21, slit 22, second support block 23 and through hole 8 are formed, are used for fixing the plastic pipe to be cut; Described support 17 is fixed on the workbench 5, and support 17 The top is fixed with a motor 16, the main shaft of the motor 16 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com