A 3D printer extrusion head trapezoidal speed curve control system

A 3D printer and speed curve technology, applied in the field of 3D printing, can solve problems such as prolonging printing time and affecting 3D printing speed, and achieve the effects of enhancing calculation stability, clear function division, and reducing data processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific details and features of the present invention will be further described in detail below in combination with embodiments.

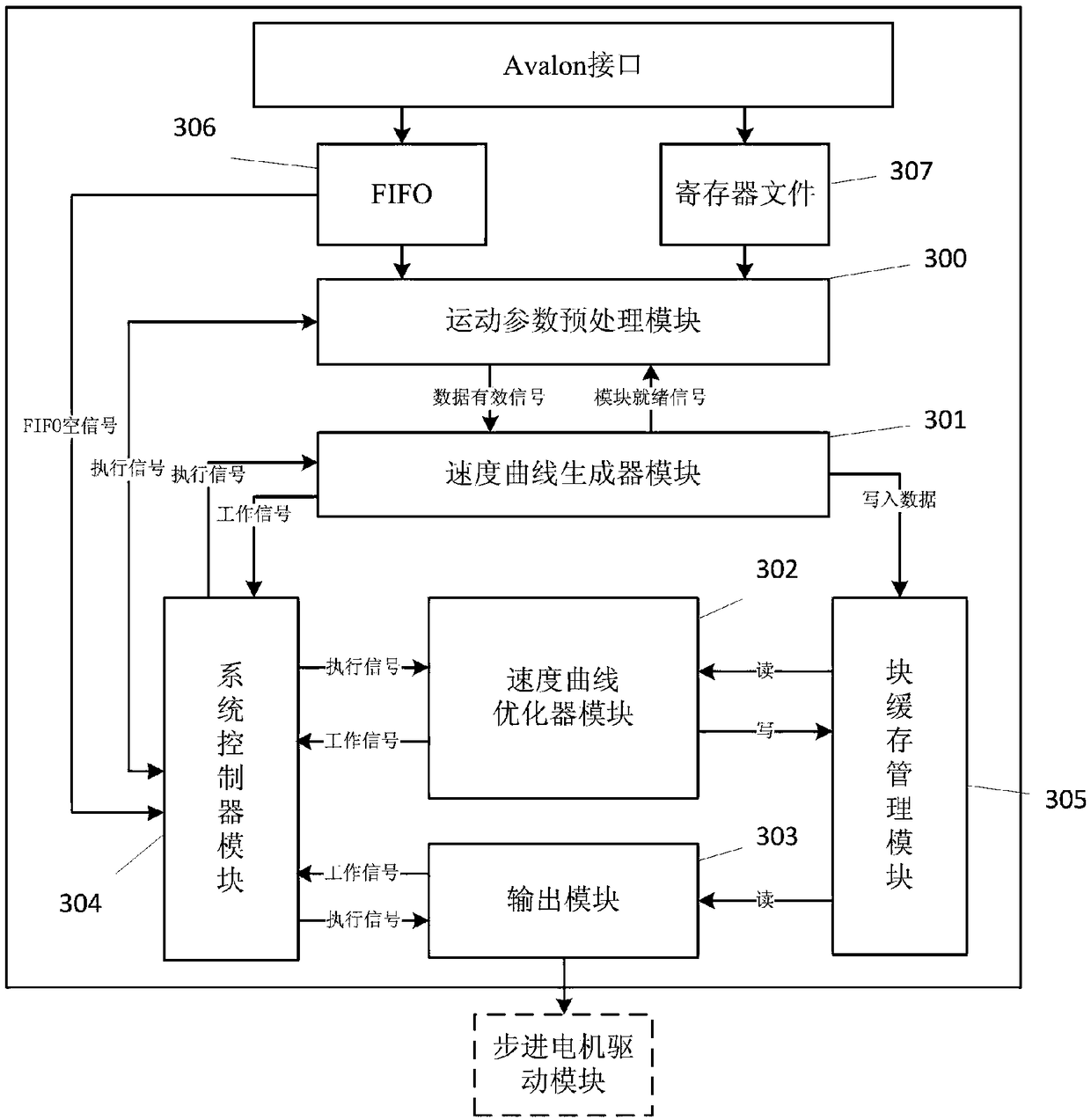

[0034] image 3 It is the overall hardware block diagram of the hardware IP core of the embodiment of the present invention. The 3D printer extrusion head trapezoidal speed curve control system includes a motion parameter preprocessing module 300, a speed curve generator module 301, a speed curve optimizer module 302, an output module 303, and a system A controller module 304 and a block cache management module 305 .

[0035] The motion parameter preprocessing module 300 is the first to be executed in the entire hardware IP core device, and its priority is above other modules, as long as the FIFO is not empty, and the signal transmitted by the system controller module 304 meets the conditions for reading the FIFO , it will continuously read out the data for calculation. Its main function is to calculate the main parameters of the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com