Automatic feeding machine for injection solution

An automatic feeding and injection technology, applied in packaging machines, conveyor objects, packaging, etc., can solve the problems of inability to adapt to labor intensity and technical operation requirements, low degree of automation, and high technical requirements for operation, and to facilitate the observation of equipment operation. situation, improve the level of automation, good visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

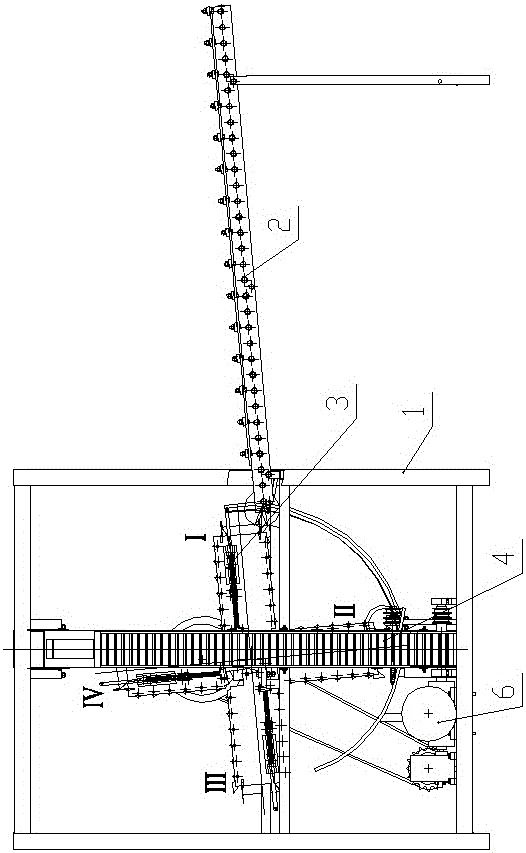

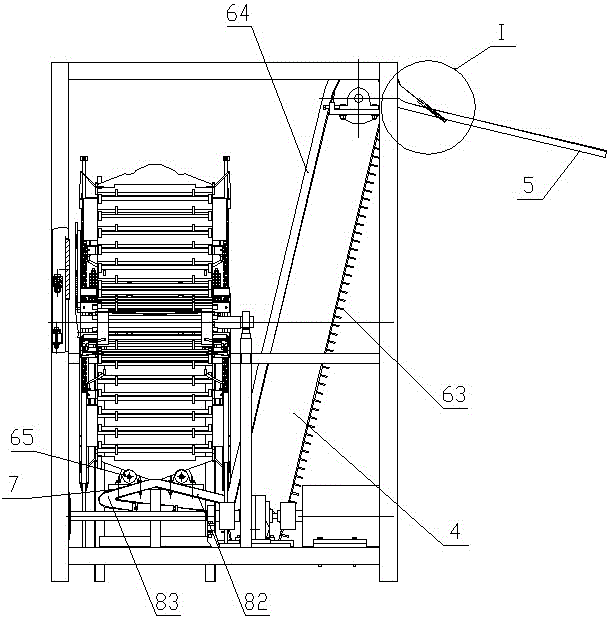

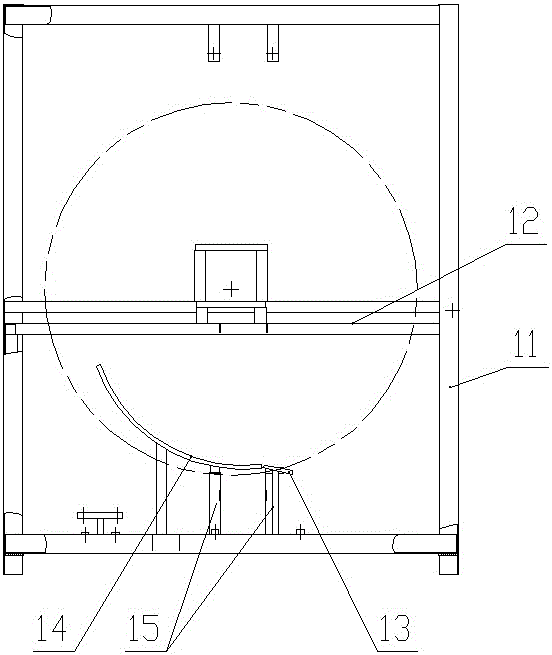

[0046] like Figure 1-15 As shown, the automatic injection feeder of the present invention includes a frame 1, the right side of the frame 1 is provided with a whole plate feeding mechanism 2, the frame 1 is provided with a material box inversion feeding device 3, and the front of the frame 1 is provided with a feeding device 3. There is a queuing conveying mechanism 4 on the side, a discharging rail 5 is arranged on the top of the front side of the rack 1, a power control system 6 is arranged at the bottom of the rack 1, and the left discharging part of the whole plate feeding mechanism 2 is turned over to the material box. The feeding part of the feeding device 3 is connected, and the discharging part of the feeding device 3 is connected to the feeding part of the queuing conveying mechanism 4 through the conveying track 7, and the discharging part of the queuing conveying mechanism 4 is connected with the feeding part of the discharging track 5. material port connection;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com