U-shaped inner surface plastic-coating steel tube protecting cap

A technology of plastic steel pipes and protective caps is applied to the protection of the ends of petroleum steel pipes. It can solve the problems of raw materials and production process, easy loosening and falling off, damage to pipe ends, etc., to achieve ideal effects, tight integration, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

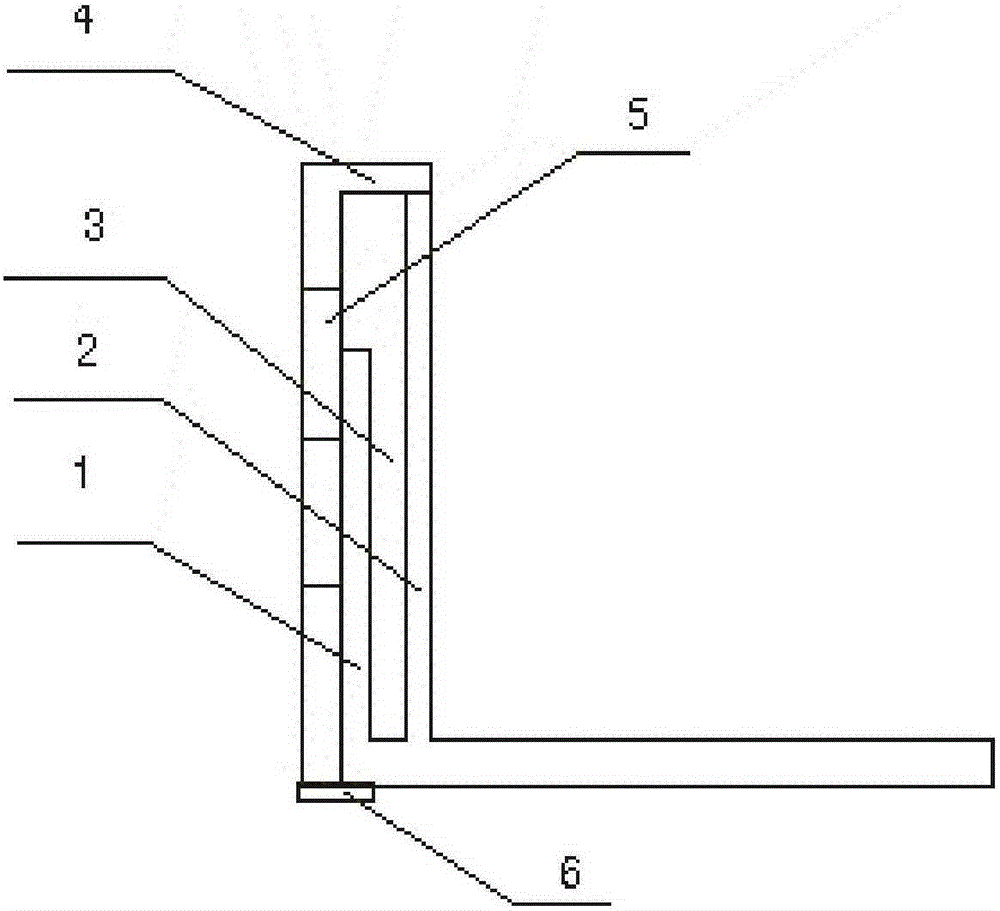

[0011] attached by figure 1 It can be seen that the present invention includes an outer wall 1 and an inner wall 2 connected as one, and a longitudinal groove 3 is formed between the outer wall 1 and the inner wall 2, and a plurality of cover strips 5 are longitudinally arranged on the top of the groove 3 along the outer wall 1, and on the topmost cover The strip 5 is bent toward the side of the inner wall 2 to form a 90° cover top 4, and is fixedly connected with the inner wall 2 to cover the top of the groove 3 formed by the outer wall 1 and the inner wall 2, where the bottommost cover strip 5 contacts the bottom of the outer wall 1 , is provided with the connecting plate 6 that prevents cover strip 5 from coming off. The cover strip 5 described in the present invention can be provided with multiple pieces, and the number of the cover strips 5 is related to the depth of the socket of the steel pipe end. The present invention is set as four pieces altogether, and each piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com