Centrifugal rotation feeder

A technology of rotary feeder and hopper, applied in the field of mechanical processing, can solve the problems of low efficiency in discharging workpieces, slow feeding speed and difficulty, and achieve the effect of improving efficiency, avoiding re-accumulation and fast feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

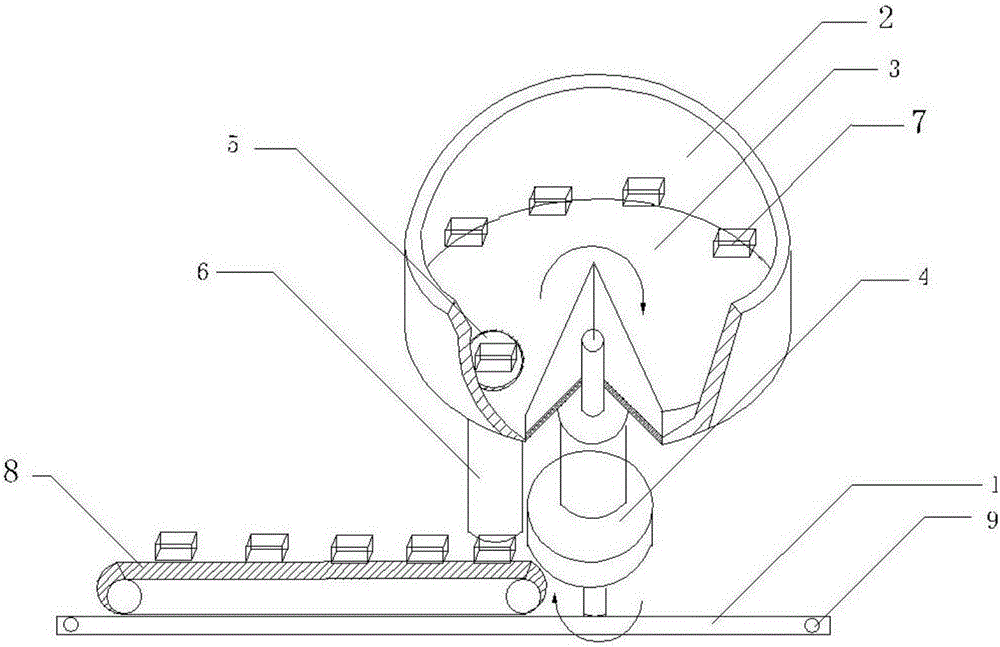

[0014] The reference signs in the drawings of the description include: machine base 1, hopper 2, cone 3, bearing 4, hole 5, conduit 6, workpiece 7, belt conveyor 8, threaded hole 9.

[0015] Example basic reference figure 1 Shown: Centrifugal rotary feeder, including machine base 1, hopper 2, cone 3, bearing 4 and conduit 6, cone 3 is arranged in hopper 2, and the bottom surface of hopper 2 is the bottom of cone 3, the bottom surface The top of the center is the apex, the lower end of the center of the cone 3 is connected to the bearing 4, the bearing 4 is installed on the base 1, and the bearing 4 drives the hopper 2 to rotate, and a hole 5 is opened at the edge of the bottom of the cone 3, and the bottom of the hole 5 is connected Conduit 6 is arranged, and belt conveyor 8 is installed below conduit 6, and its belt conveyor 8 is installed on the support 1.

[0016] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com